Platinum-gallium catalyst loaded on double-oxide composite carrier as well as preparation method and application of platinum-gallium catalyst

A composite carrier and double oxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst supports, etc., can solve the problem of carbon deposition, deactivation selectivity, and Low propylene selectivity and other problems, to achieve the effect of improving oxygen storage capacity, improving oxygen moving capacity, and high dehydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dissolve 0.5046g of cerium nitrate hexahydrate in 3g of deionized water, and dissolve 1.8g of Al 2 o 3Soak in the above solution, ultrasonic for 30min, dry at room temperature for 12h, and dry at 80°C for 12h;

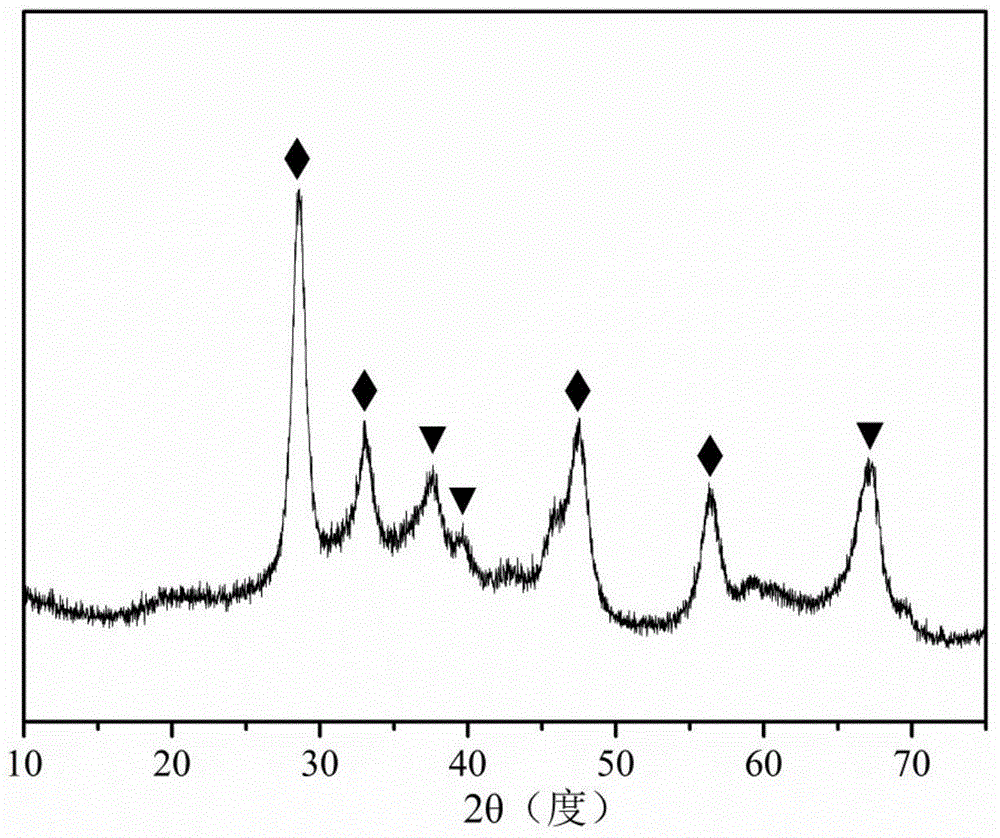

[0031] (2) Calcining the solid obtained in (1) at 600°C for 3h to obtain the composite oxide support CeO 2 -Al 2 o 3 ;

[0032] (3) Dissolve 0.36g of gallium nitrate in 3g of deionized water, and dissolve 2g of CeO 2 -Al 2 o 3 Immerse in the above solution, then add chloroplatinic acid solution with a concentration of 0.01g / mL, sonicate for 30min, dry at room temperature for 12h, and dry at 80°C for 12h;

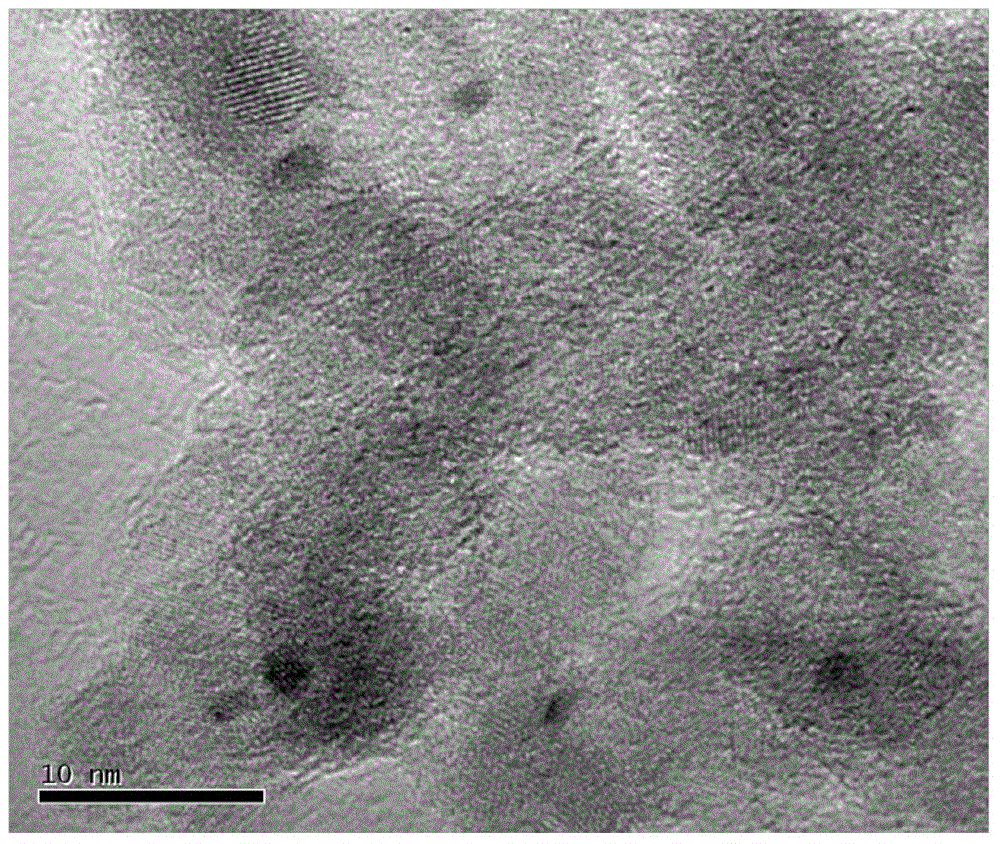

[0033] (4) Calcinate the solid obtained in (2) at 600°C for 3h to obtain PtGaOx / CeO 2 -Al 2 o 3 , and finally at 500°C H 2 Reduction under the atmosphere for 1h, the PtxGa / yCeAl catalyst was obtained. where x and y are Ga and CeO respectively 2 In the mass content percentage in the catalyst, x is 3, and y is 10.

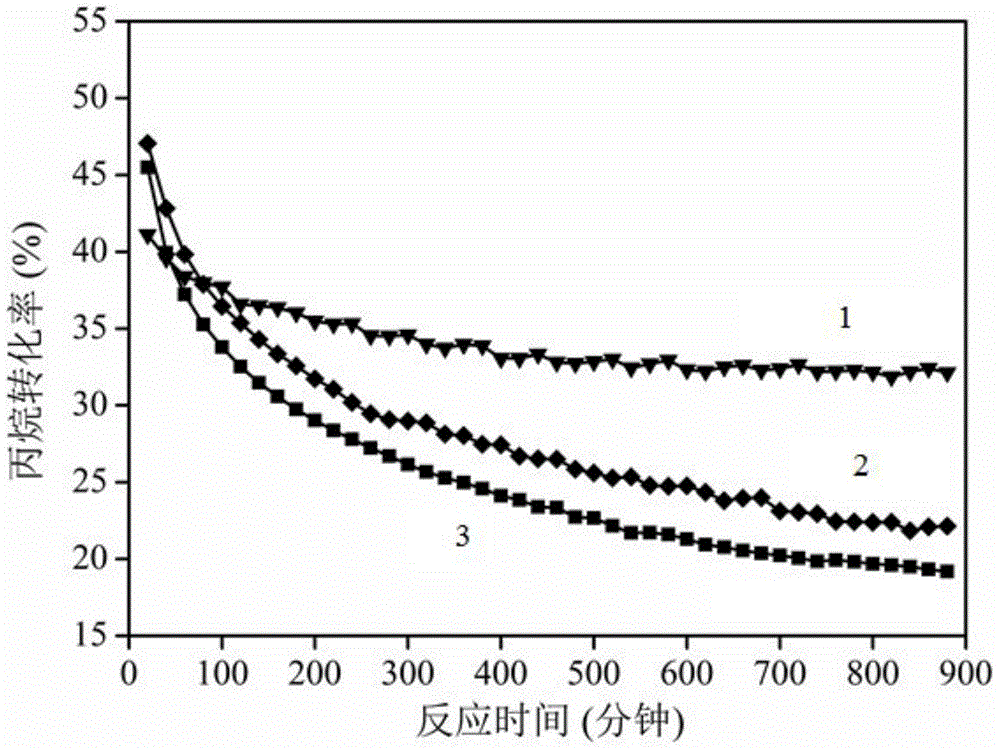

[0034] (5) Pt3Ga / 10CeAl 3 T...

Embodiment 2

[0048] Adopt the method of embodiment 1 to react, and its difference is only that the quality of the cerium nitrate hexahydrate of step (1) is 0.2523g, and the obtained catalyst y is 5.

Embodiment 3

[0050] Adopt the method of embodiment 1 to react, and its difference is only that the quality of the cerium nitrate hexahydrate of step (1) is 0.7570g, and the obtained catalyst y is 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com