A kind of preparation method of red yeast vinegar beans

A technology of red koji vinegar and red koji vinegar mash, which is applied to the functions of food ingredients, food science, and applications. It can solve the problems of less vinegar absorbed by soybeans, a long preparation cycle of vinegar beans, and a single applicable taste. Affect blood sugar rise, short fermentation cycle, easy to accept effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

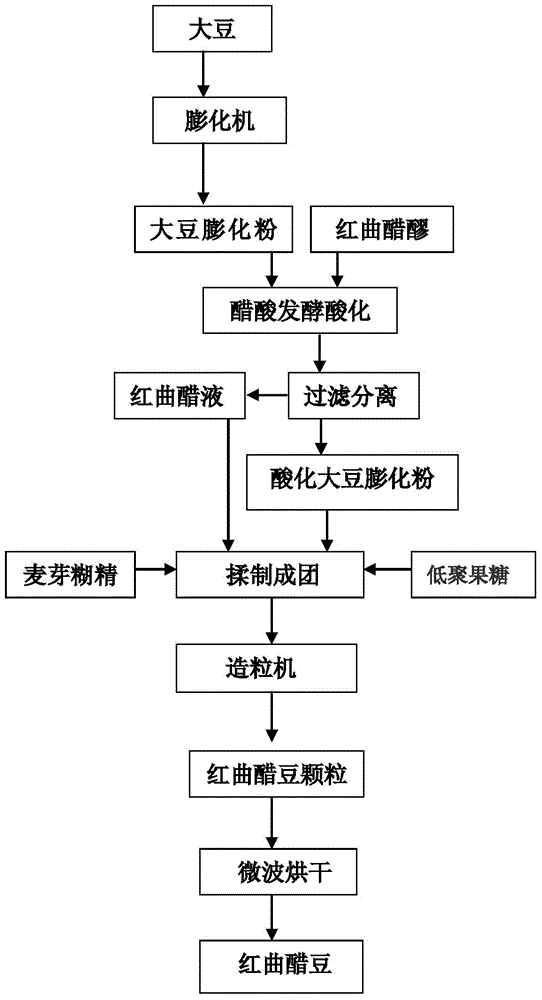

Method used

Image

Examples

Embodiment 1

[0022] (1) Soybean puffed powder production: 150 kg of clean soybeans are ground first, and the crushing degree is 3.0mm sieve plate. Inject steam into the conditioning machine to increase the moisture content of soybeans to 17%, and the soybean product temperature reaches 90°C, and then through the screw shaft of the extruder, the soybeans are extruded at 160°C by rotation and friction in the rotary extruder. , sprayed out from the small hole of the pointed outlet, extruded and then dried and cooled to 45°C to obtain 158 kg of soybean puffed powder.

[0023] (2) Acidification by acetic acid fermentation: Add 30 kg of puffed soybean powder for every 100 kg of red yeast rice vinegar mash. Requirements for red yeast rice vinegar mash: the acidity of red yeast rice vinegar mash with a one-year fermentation period is brewed by the traditional division method of acetic acid liquid fermentation process, with an acidity of 50g / L. The temperature of the fermentation room is required ...

Embodiment 2

[0035] (1) Production of puffed soybean powder: 100 kg of clean soybeans are ground first, and the crushing degree is passed through a 3.0mm sieve plate. Inject steam into the conditioning machine to increase the soybean moisture to 16%, and the soybean product temperature reaches 80°C, and then through the screw shaft of the extruder, the soybeans are extruded at 170°C by rotation and friction in the rotary extruder. , sprayed out from the small hole of the pointed outlet, extruded and then dried and cooled to 50°C to obtain 103 kg of soybean puffed powder.

[0036] (2) Acidification by acetic acid fermentation: Add 30 kg of puffed soybean powder for every 100 kg of red yeast rice vinegar mash. Requirements for red yeast rice vinegar mash: the acidity of red yeast rice vinegar mash with a one-year fermentation period is brewed by the traditional division method of acetic acid liquid fermentation process, with an acidity of 40g / L. The temperature of the fermentation room is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com