Selenium-rich shiitake mushroom production process

A production process and selenium-enriched technology, which is applied in horticulture, mushroom cultivation, botanical equipment and methods, etc., can solve the problems of mushroom planting hazards, achieve safe absorption and utilization, eliminate toxic and side effects and gastrointestinal irritation, and achieve large economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A production process of selenium-enriched shiitake mushrooms, the described production process of selenium-enriched shiitake mushrooms is carried out according to the following steps:

[0026] The first step: ingredient pretreatment:

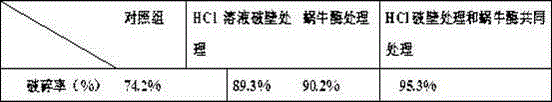

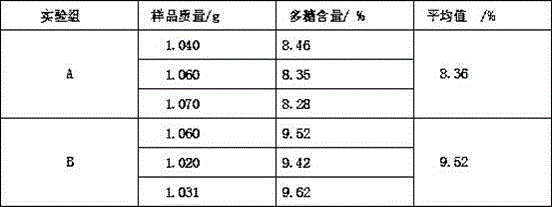

[0027] Soak the active selenium-enriched yeast in 3 mol / L HCl solution for 60 minutes before batching, heat-treat for 3-5 minutes, and cool down rapidly for wall-breaking pretreatment, and soak chestnut shells in 2-fold diluted biogas slurry for 5- Pulverize after 6 h;

[0028] The second step: preparation;

[0029] To make mushroom compost, 35 parts of wood chips, 16 parts of chestnut shells, 18 parts of wheat bran, 20 parts of corncobs, 5 parts of bagasse, 3 parts of sugar, 1 part of gypsum, 0.85 parts of superphosphate, 0.15 parts of carbendazim, The ratio of 1 part of active selenium-enriched yeast is used to make the compost and mixed evenly;

[0030] The third step: Sterilize in the pot;

[0031] Use a boiling steam pot to kill ...

Embodiment 2

[0037] As preferably, described a kind of selenium-enriched shiitake mushroom production technology is carried out according to the following steps:

[0038] The first step: ingredient pretreatment:

[0039] Before batching, the cultured active selenium-enriched Septoria gossypiae was treated with helicase for 2-3 hours, then soaked in 3 mol / L HCl solution for 60 minutes, heat-treated for 3-5 minutes, and cooled rapidly to break the wall Pretreatment, soaking the chestnut shells with 2 times diluted biogas slurry for 5-6 h and crushing;

[0040] The second step: preparation;

[0041] To make mushroom compost, 35 parts of wood chips, 16 parts of chestnut shells, 18 parts of wheat bran, 20 parts of corncobs, 5 parts of bagasse, 3 parts of sugar, 1 part of gypsum, 0.85 parts of superphosphate, 0.15 parts of carbendazim, The ratio of 1 part of active selenium-enriched yeast is used to make the compost and mixed evenly;

[0042] The third step: Sterilize in the pot;

[0043] Us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com