Integrated phase connection isolator with individual phase isolator

A technology of isolators and phase separators, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, electric components, etc., can solve problems such as reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

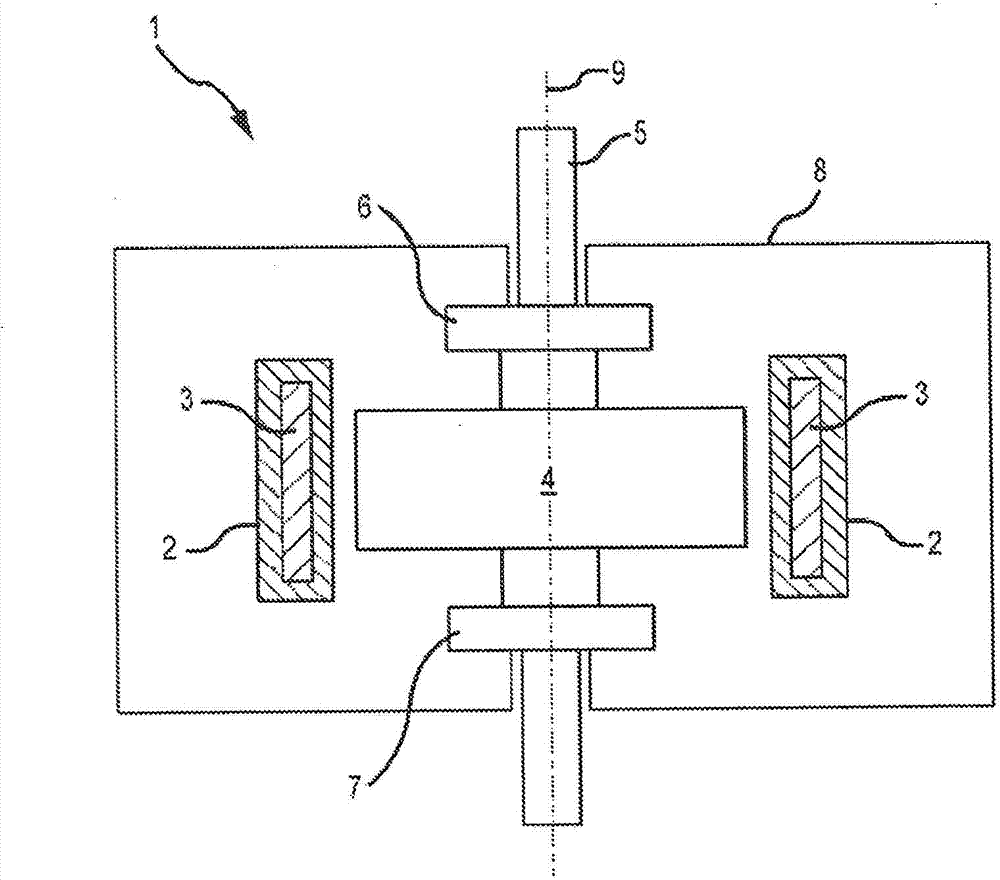

[0029] figure 1 Is a schematic illustration of an exemplary electric machine 1 having a stator 2 comprising a stator winding 3, eg one or more coils. The annular rotor body 4 may also comprise windings and / or permanent magnets and / or conductor bars formed eg by a molding process. The rotor body 4 is part of a rotor comprising an output shaft 5 supported by a front bearing assembly 6 and a rear bearing assembly 7 . The bearing assemblies 6 , 7 are fixed to the housing 8 . In general, the stator 2 and rotor body 4 are substantially cylindrical in shape and concentric with a central longitudinal axis 9 . Although the rotor body 4 is shown as being radially inside the stator 2 , alternatively, the rotor body 4 may be formed radially outside the stator 2 in various embodiments. The electric machine 1 may be a motor / generator or other device. In an exemplary embodiment, the electric machine 1 may be a traction motor for a hybrid vehicle or an electric vehicle. The housing 8 may...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com