An ultra-high frequency sensor for on-line monitoring of partial discharge inside a switchgear

A technology of ultra-high frequency sensors and partial discharge, which is applied in the direction of testing dielectric strength, etc., can solve the problems of low gain, low efficiency, and narrow bandwidth of ultra-high frequency sensors, and achieve the effects of high sensitivity, easy manufacture, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings. For comparison with the present invention, a conventional microstrip antenna is first described.

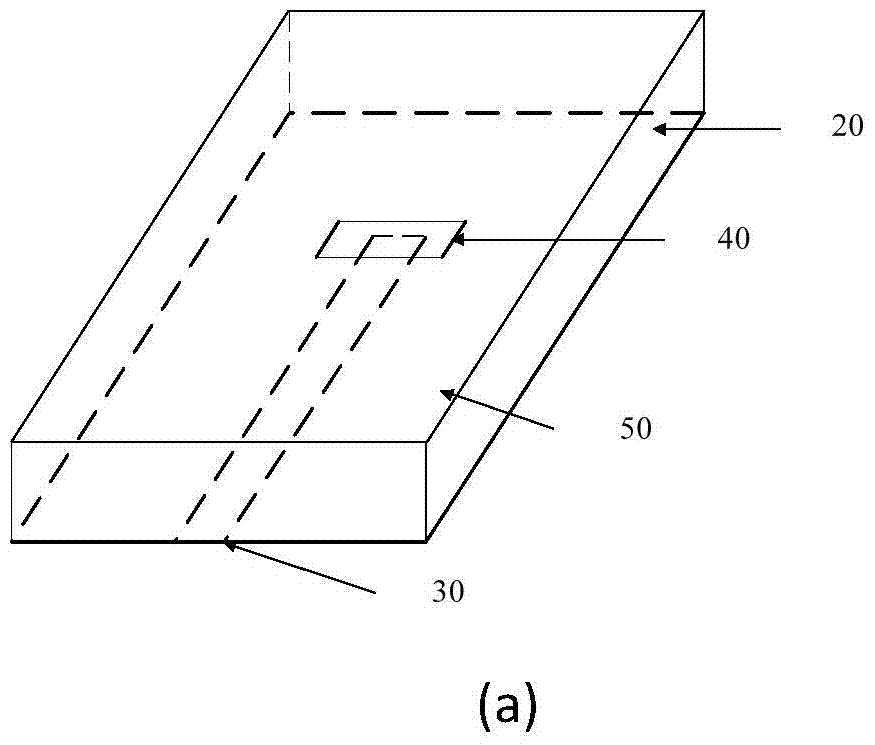

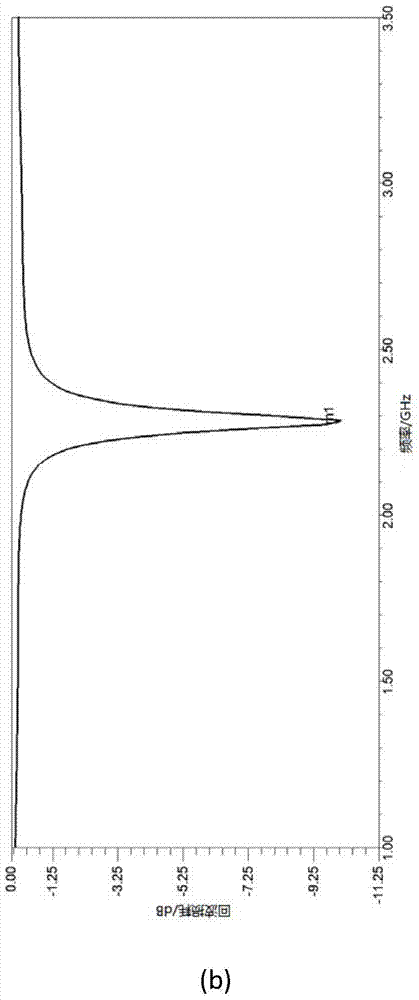

[0035] see figure 1 (a) to figure 1 As shown in (c), the radiation mechanism of the microstrip antenna will be described. for figure 1 The rectangular patch microstrip antenna shown in (a) theoretically uses the transmission line model to analyze its performance. figure 1 The rectangular patch microstrip antenna shown in (a) includes a rectangular dielectric substrate 20 on which a radiation patch 10 is pasted, and the radiation patch 10 is connected to a feeder 30 . Assume that the length of the radiation patch 10 is approximately half a wavelength, the width is w, the thickness of the dielectric substrate 2 is h, and the working wavelength is λ. The radiation patch 10, the dielectric substrate 20 and the ground plane can be regarded as a low-impedance micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com