A preparation method of nano-ink for silk printing based on cellulose nanospheres as dispersant

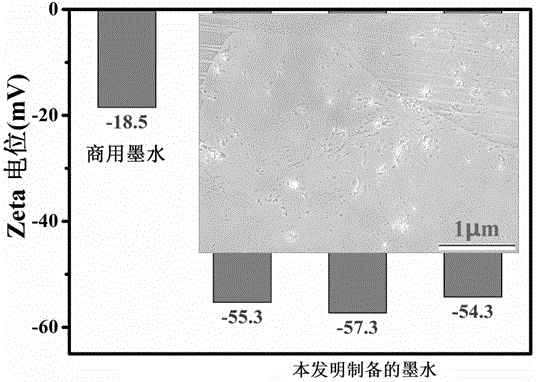

A nano-ink and dispersant technology, applied in dyeing, textile and papermaking, etc., can solve the problems of small particle size, unsmooth printing, narrow distribution, etc., and achieve small particle size, good conductivity and narrow distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Mix 5 g of red reactive dye with 0.7 g of uniformly dispersed cellulose nanosphere suspension, stir well, then add 1 g of sodium dodecylsulfonate, and stir ultrasonically for 30 min. Add 3 g of glycerol and 0.01 g of silver nitrate respectively, and stir thoroughly. The pH value of the solution was adjusted to 7.0 with 2 mol / L disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution. Stir well at 50°C for 1 h, then cool to room temperature, continue to stir for 0.5 h, stand at 50°C for 3 h to mature; repeat filtration through a nanofiltration membrane with a pore size of 500 nm three times, ultrasonically disperse and remove the solution The bubbles in the ink can be used to prepare nano-ink for silk printing.

Embodiment 2

[0035]Mix 10 g of cyan reactive dye with 2 g of uniformly dispersed cellulose nanocrystal sphere suspension, stir well, then add 2 g of sodium dodecylsulfonate, and stir ultrasonically for 50 min. Add 3 g of ethylene glycol and 0.2 g of zinc nitrate respectively, and stir thoroughly. Adjust the pH value of the solution to 7.3 with 0.05mol / L phthalic acid-hydrochloric acid buffer solution. Stir well at 65°C for 1 h, then cool to room temperature, continue to stir for 0.5 h, and stand at 70°C for 3 h to mature; repeat filtration through a nanofiltration membrane with a pore size of 100 nm three times, ultrasonically disperse and remove the solution The bubbles in the ink can be used to prepare nano-ink for silk printing.

Embodiment 3

[0037] Mix 15 g of red reactive dye with 0.5 g of uniformly dispersed cellulose nanosphere suspension, stir well, then add 0.5 g of sodium lauryl sulfate, and stir ultrasonically for 40 min. Add 1 g diethylene glycol and 0.02 g silver nitrate respectively, and stir well. The pH value of the solution was adjusted to 7.8 with 1mol / L disodium hydrogen phosphate-citric acid buffer solution. Stir well at 70°C for 1 h, then cool to room temperature, continue to stir for 0.5 h, and stand at 65°C for 3 h to ripen; repeat filtration through a nanofiltration membrane with a pore size of 500 nm three times, ultrasonically disperse and remove the solution The bubbles in the ink can be used to prepare nano-ink for silk printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com