Cold sizing device for making shoes

A cold-setting, shoe-use technology, applied in shoe uppers, footwear, applications, etc., can solve problems such as disadvantages, and achieve the effect of saving energy and increasing interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

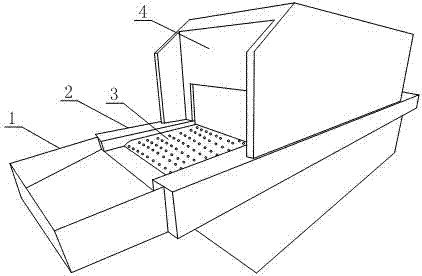

[0025] Such as figure 1 , A cold setting device for shoemaking, comprising a frame 2, a freezing chamber 4, at least two pulleys and a conveyor belt 3. The freezing chamber 4 and the two pulleys are fixedly connected to the frame 2, and the conveyor belt 3 is arranged On the plurality of pulleys, the conveyor belt 3 is a polyurethane conveyor belt, and the working surface of the pulley 3 is provided with a plurality of convex points.

[0026] Under the high conveying speed of the conveyor belt, the multiple bumps arranged on the conveyor belt can produce a large interaction force along the working surface of the conveyor belt under the action of the gravity of the shoes, so that the shoes can move together with the conveyor belt in a short time and prevent The shoes are slipping on the conveyor belt; the conveyor belt is set as a polyurethane conveyor belt, which aims to have a certain elasticity. Some of the polyurethane conveyor belts extend and compensate for deformation when ...

Embodiment 2

[0028] This embodiment is further improved on the basis of embodiment 1, such as figure 1 , The cold setting device for shoemaking includes a frame 2, a freezing cavity 4, and also includes a shoe pocket 1, a freezing cavity entrance door and a freezing cavity outlet door. The outlet end of the cold setting device for shoemaking on the frame 2 is welded A connecting nut, the shoe pocket 1 and the connecting nut are screwed and fixed by bolts, the freezing chamber entrance door is hingedly connected to the inner wall of the freezing chamber 4 at the entrance of the freezing chamber 4, and the freezing chamber outlet door is hingedly connected to the freezing chamber 4 The outer wall of the shell of the freezing chamber 4 at the outlet is hingedly connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com