Method and apparatus for separation of molybdenite from pyrite containing copper-molybdenum ores

A pyrite and ore technology, applied in solid separation, flotation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

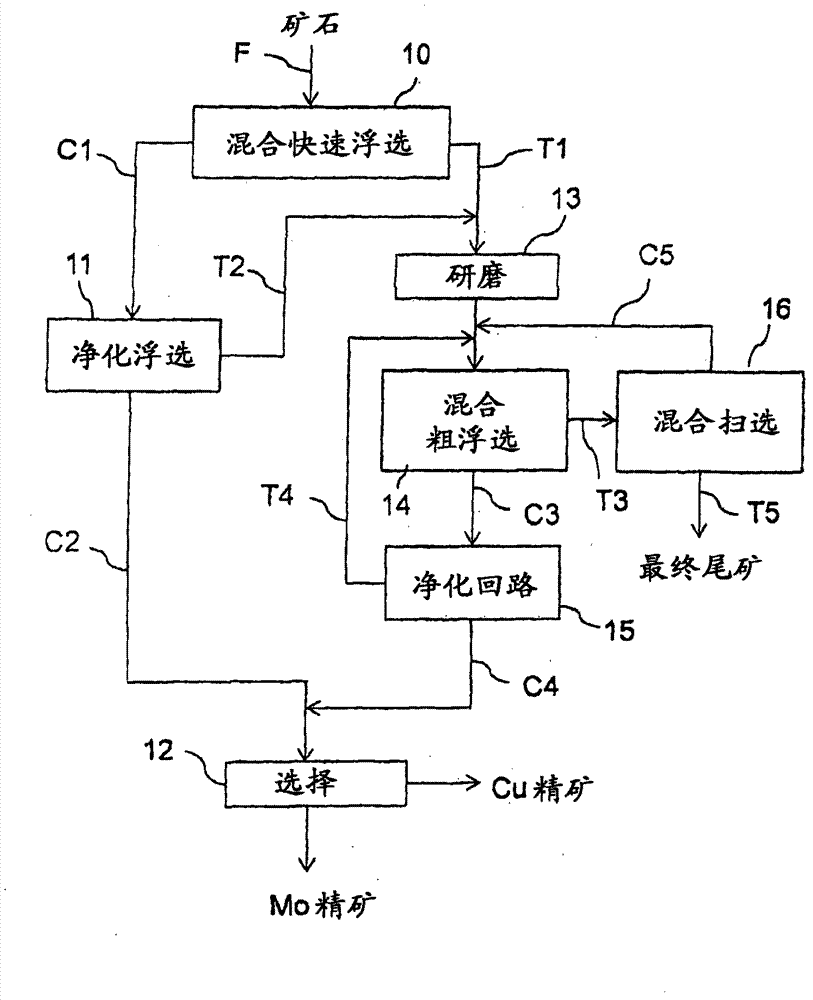

Method used

Image

Examples

Embodiment 1

[0061] Four hybrid rapid flotation tests were performed at laboratory scale using ore bodies from Deposit A in Table 1, and four different reagent combinations. The reagents used in the tests are shown in Table 2.

[0062] Table 2

[0063] Test serial number

Reagents used in fast flotation

5

Na 2 CO 3 +fuel oil+xanthates

11

Na 2 CO 3 +fuel oil+Na 2 S

13

Na 2 CO 3 +fuel oil+Na 2 S+xanthate

17

Na 2 CO 3 + fuel oil

[0064] The results of the rapid flotation tests are shown in Table 3. The values in each column describe the recovery of each chemical element (Cu, Fe, Mo, S) in the fast flotation concentrate expressed as a percentage by mass of the initial content of the element in the ore body. The last column describes the sulphide content in the concentrate.

[0065] table 3

[0066] Test serial number

Cu%

Fe%

Mo%

S%

Sulfide %

5

52.4

15.2

47...

Embodiment 2

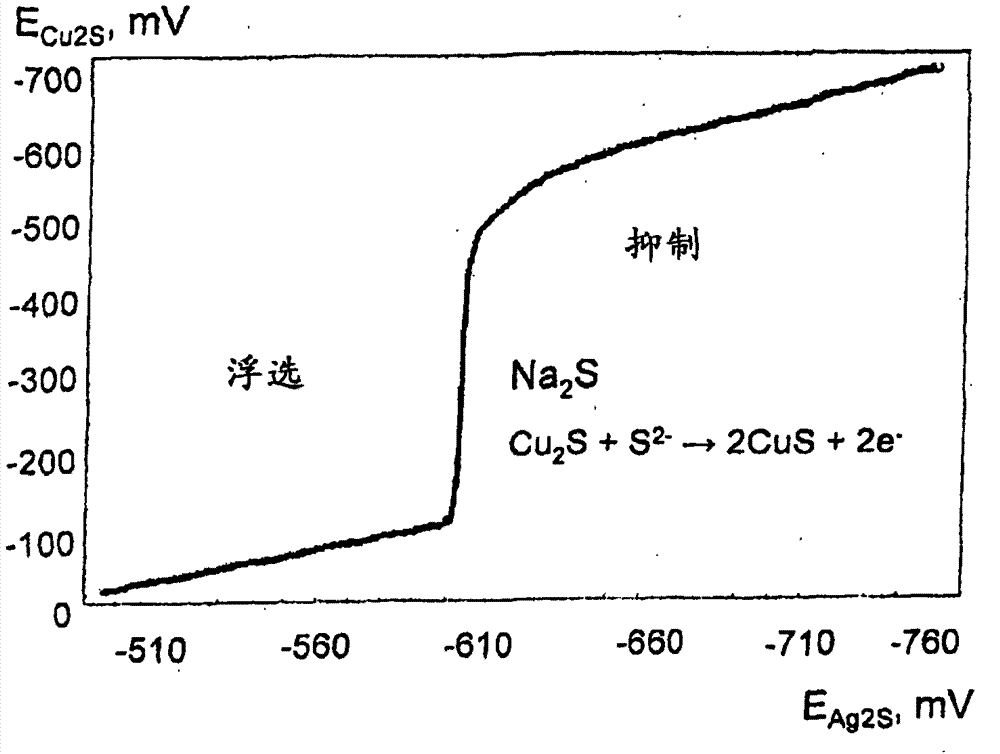

[0074] Optimal dosages of soda ash and sodium sulfide in the mixed flash flotation step were examined in terms of consistency with the new method during small-scale testing. Different conditions for slurry preparation in Figure 4 described in , where the arrows indicate the order of the conditions tested, including first adding Na at 800 g / t, 1200 g / t and 1500 g / t 2 CO 3 , then Na 2 CO 3 Add a small amount of Na together 2 S. Finally, 10g / t of Na was tested 2 S and 200g / t Na 2 CO 3 The combination. Combined with the conditions tested, the reduction potential (Eh vs. SHE) and pH of the slurry were measured. Tests show that using 10g / t of Na 2 S and 200g / t Na 2 CO 3 combination can give good results.

[0075] It was found that the optimum dosage of soda ash and sodium sulphide can be achieved when the relationship between Eh and pH is in the following region:

[0076] Eh=E 0 -59pH (1)

[0077] where for the following reactions, E 0 =437...457:

[0078] CuFeS ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com