Non-linear process industry fault prediction method based on novel FDE-ELM and EFSM

A fault prediction and non-linear technology, applied in electrical test/monitoring, test/monitoring control systems, instruments, etc., can solve problems such as inaccurate representation, inaccurate analysis of the relationship between variables, complex mathematical models, etc., to improve generalization The effect of low accuracy, complex solution model, and high generalization accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

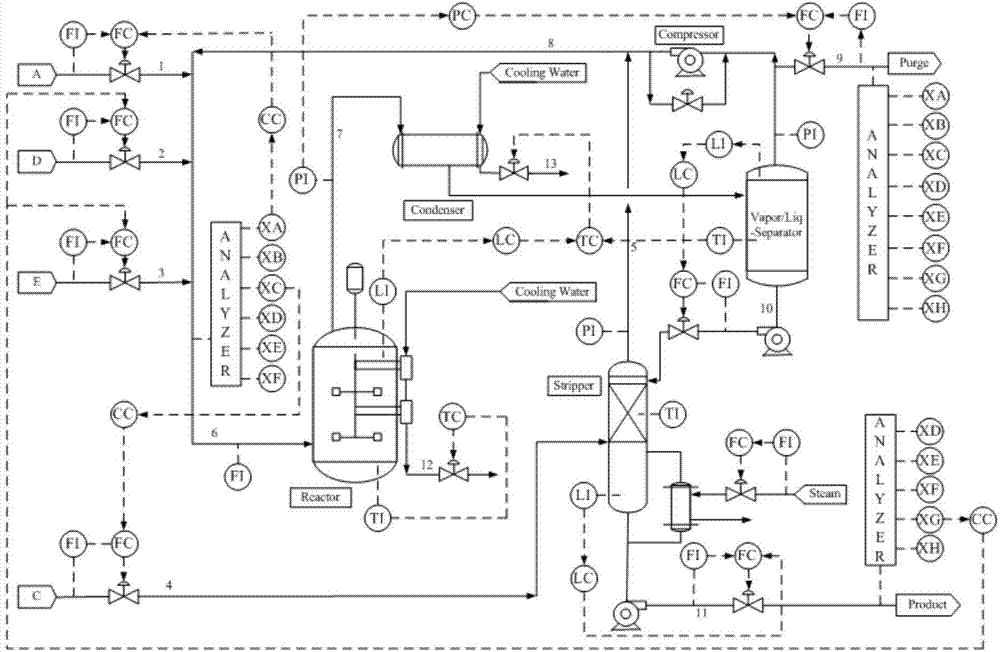

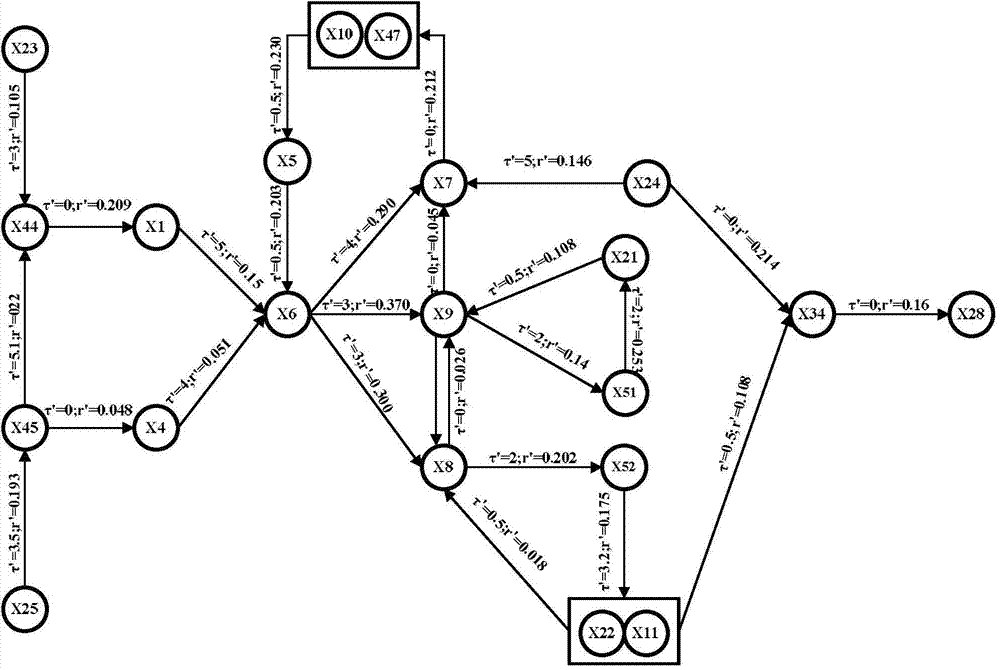

[0028] Such as figure 1Shown is the working flow diagram of the method of the present invention. (1) Data preprocessing process: This process mainly performs noise reduction processing on industrial data to avoid affecting the accuracy of subsequent operation results due to noise interference. (2) Time-delay EFSM model construction process: This process mainly uses TDMI to calculate the delay time and correlation analysis of the preprocessed data, build a data dependency graph, and build the state through prior knowledge and mechanism analysis of the model Dependency graphs and migration tables reduce complex process industry objects to simple models, clearly showing the internal connections between system variables, the internal connections between states, and the interrelationships between states and variables. (3) Variable prediction process based on FDE-ELM: This process is to use FDE-ELM network to predict possible abnormalities in process industry operation. When const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com