LCD panel

A display panel and display area technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of positional accuracy variation, difficult control of cutting accuracy, uneven section of liquid crystal display panel, etc., to meet the needs of easy design and improve product quality rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

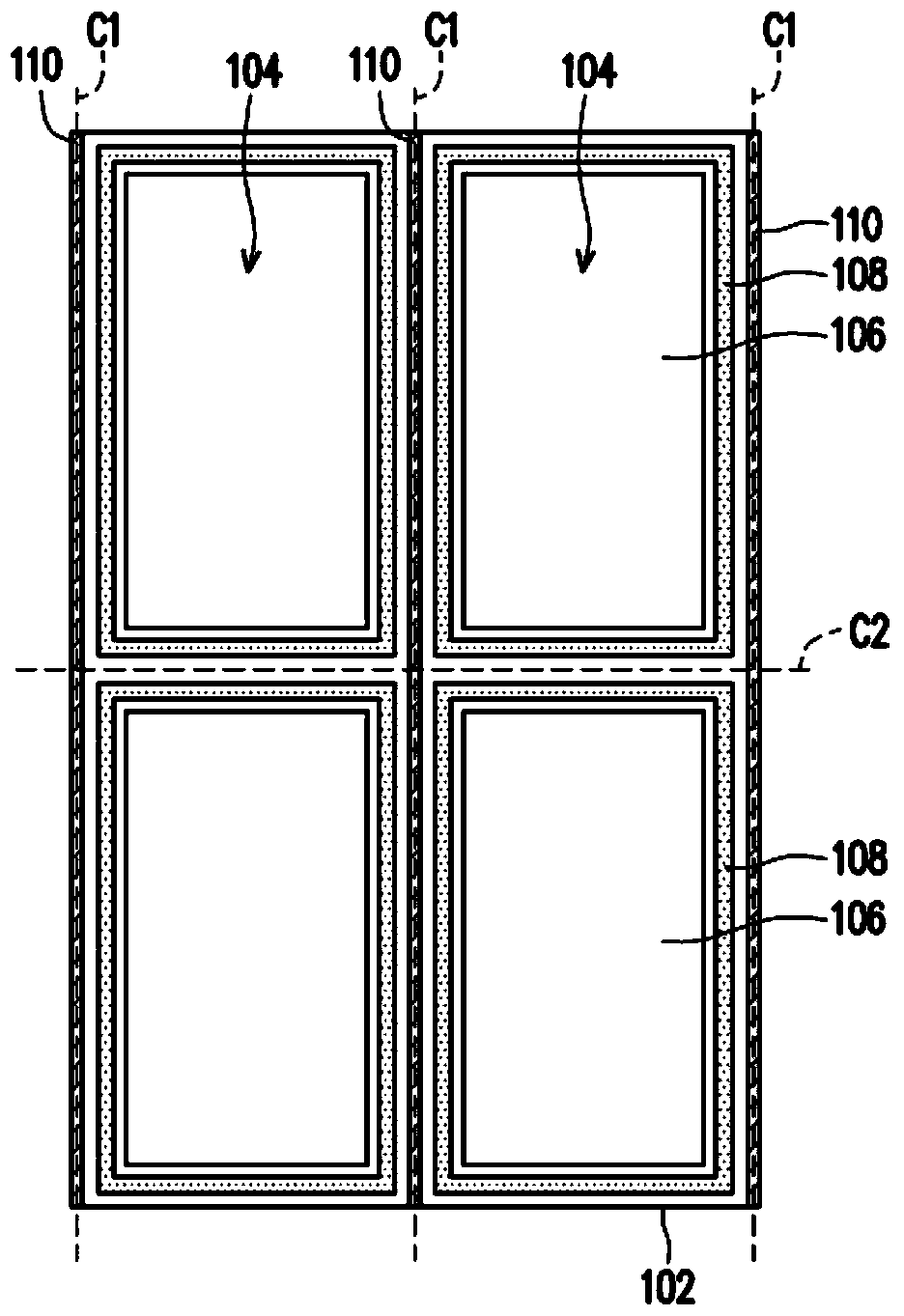

[0060] Generally speaking, a liquid crystal display panel is mainly composed of two substrates and a liquid crystal layer sandwiched between the two substrates. Based on the consideration of mass production efficiency, multiple liquid crystal display panels are efficiently produced. In the production process, multiple liquid crystal display panels are usually formed on two large mother substrates. Each liquid crystal display panel includes active components, for example. array, color filter pattern, black matrix and other required component structures, two mother substrates are bonded together and injected into the liquid crystal layer to complete the production of multiple liquid crystal display panels at the same time. Afterwards, the laminated mother substrate is cut into a plurality of independent liquid crystal display panels (or called liquid crystal display units) through cutting and slitting processes.

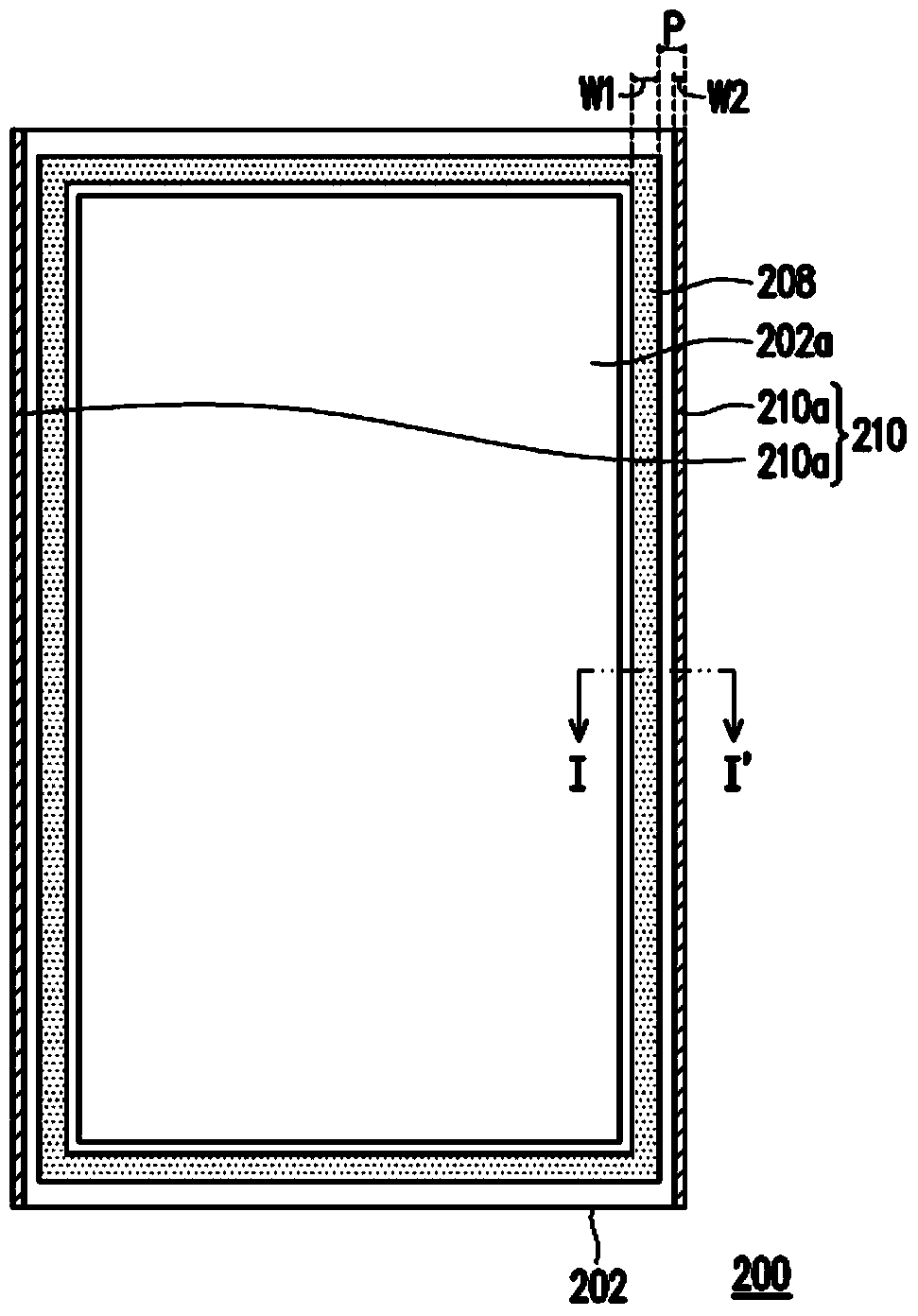

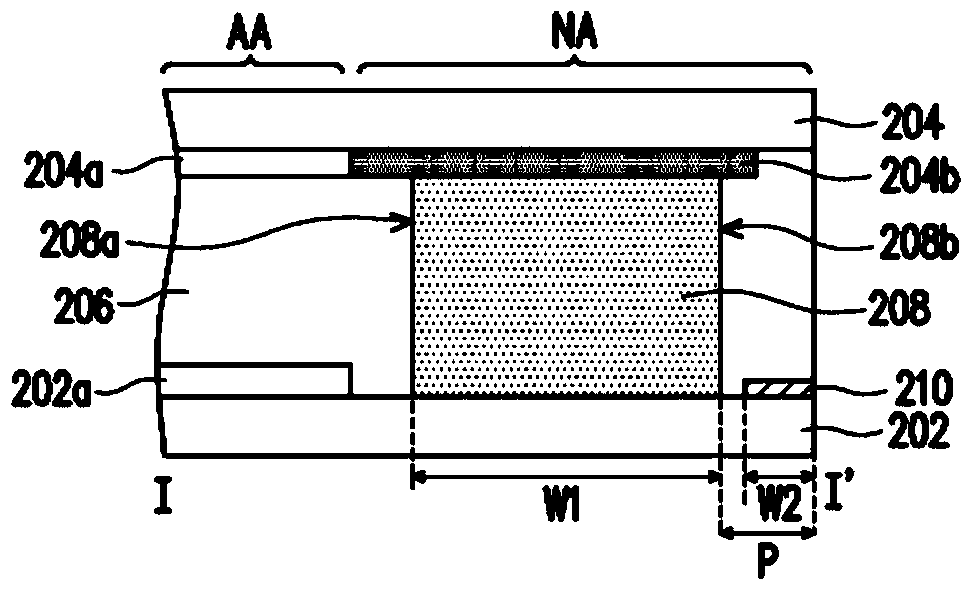

[0061] figure 1 is a schematic top view of a motherboard accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com