Laser beam combination system

A laser beam combining and laser technology, which is applied in the field of frequency doubled lasers, can solve problems affecting industrial processing speed, X-Y axis asymmetry, and affecting processing effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

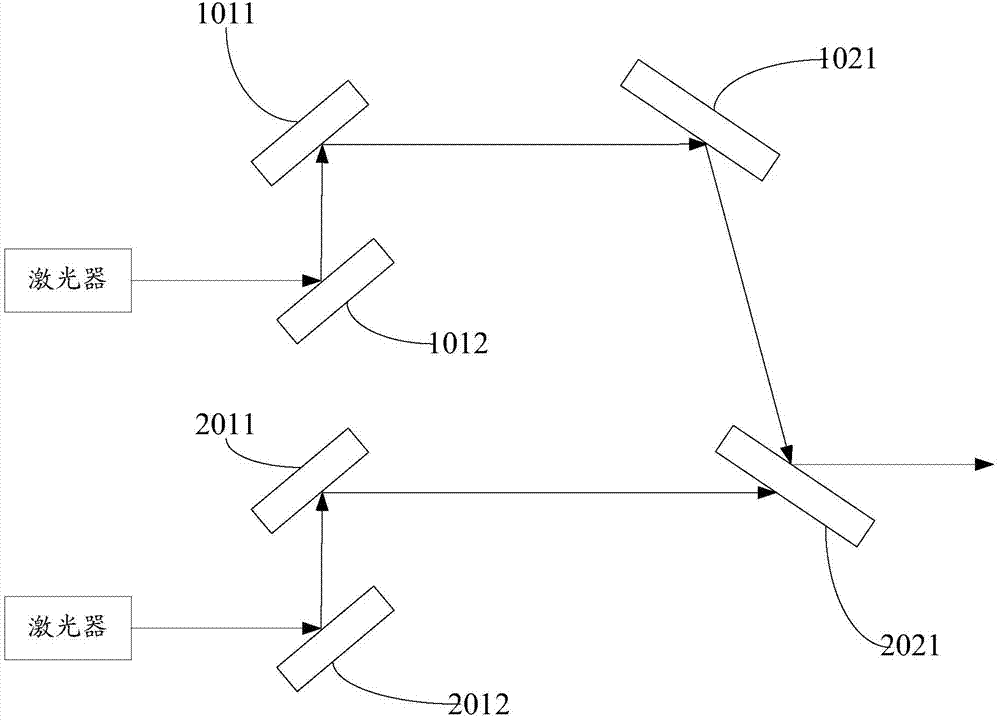

[0023] like figure 1 Shown is the block diagram of the laser beam combining system.

[0024] A laser beam combining system is used to combine two laser beams into one laser beam, including a first total reflection module 101 , a second total reflection module 201 , a first polarization module 102 and a second polarization module 202 .

[0025] The first total reflection module 101 is used to reflect the S polarization laser to the first polarization module 102; the first polarization module 102 is used to reflect the incident S polarization laser to the second polarization module 202 , the second polarization module 202 is configured to reflect the incident S-polarized laser light.

[0026] The second total reflection module 201 is used to reflect the P polarization state laser to the second polarization module 202; the second polarization module 202 is used to refract the incident P polarization state laser light to the second polarization module. 202 on the optical path of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com