In-situ testing platform for thermal chemical vapor deposition

A technology of in-situ testing and vapor deposition, which is applied in material analysis, measuring devices, and scientific instruments using wave/particle radiation. Complicated operation and other issues, to achieve the effect of quick disassembly, easy disassembly and assembly, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

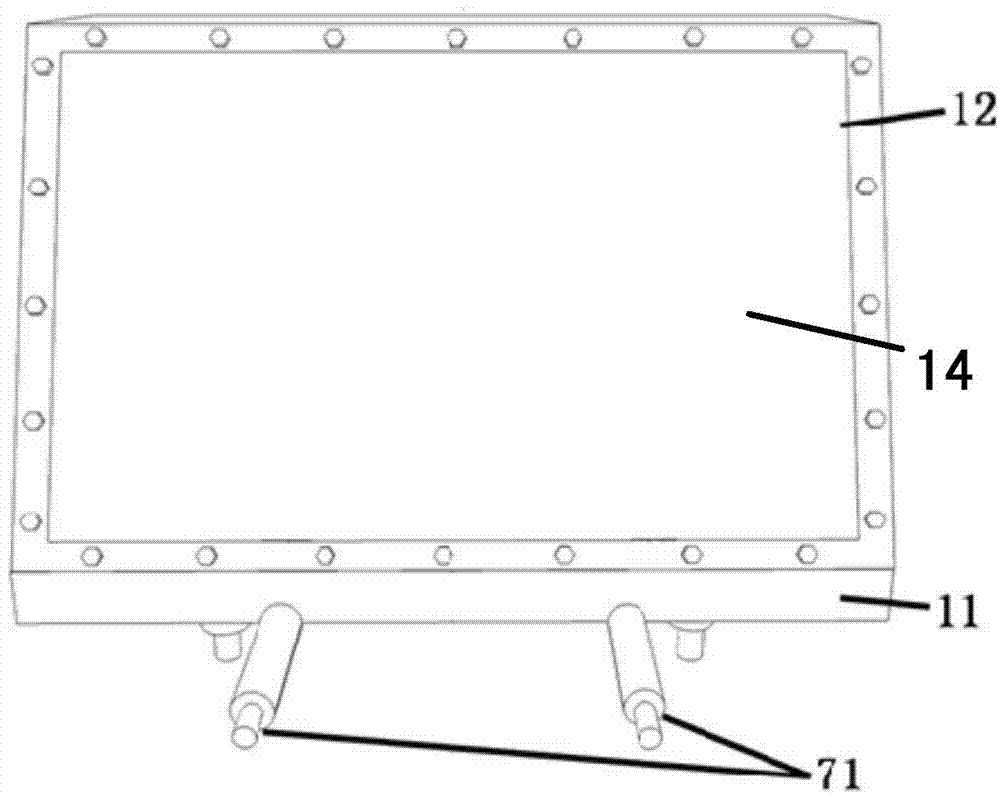

[0035] Such as figure 1 As shown, the in-situ test platform capable of performing thermal chemical vapor deposition of the present invention includes: a high-temperature hot-stage reaction chamber 1 that can be arranged on a base 8 in an x-ray testing instrument, a high-temperature hot-stage reaction chamber 1 installed The ceramic heating table 2 inside, the temperature control system 3 connected with the ceramic heating table 2, the vacuum system 4 communicated with the high temperature heating table reaction chamber 1, the reaction gas mixing system 5 and the vacuum measurement system 6, and the The circulating water cooling system 7 on the bottom surface of the reaction chamber body 1 of the hot stage.

[0036] Each part in this embodiment is described in detail below:

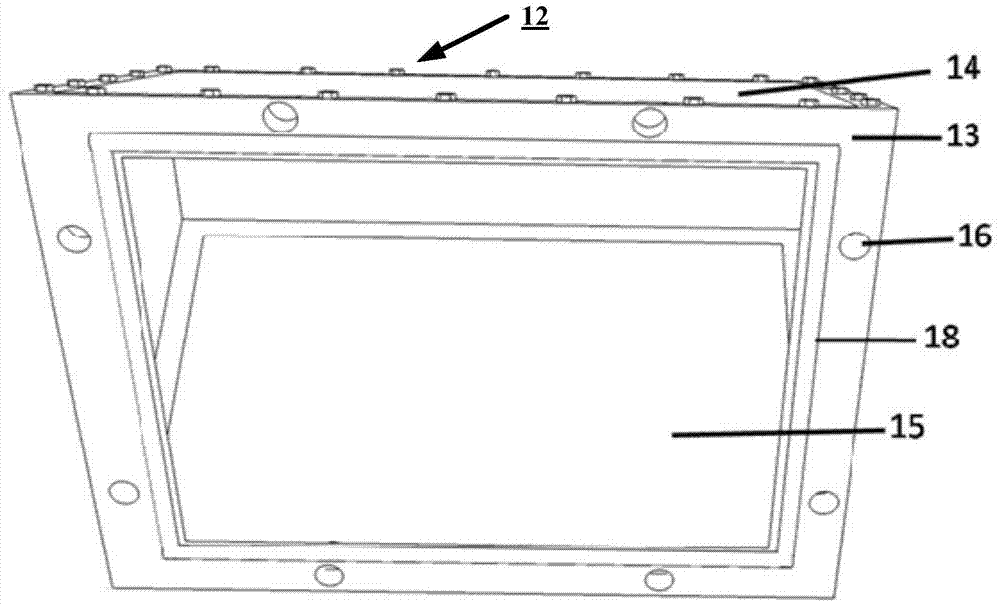

[0037] Such as figure 2 and 4 As shown, the high-temperature hot-stage reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com