A drying kiln system for mixed application of radiator and furnace gas

A technology of mixed application and radiator, which is applied to the dryer of static materials, the arrangement of drying gas, the local stirring dryer, etc. It can solve the problem of gas utilization of hot oil furnace that is not mentioned, and meet the requirements of drying and waste heat utilization. Recovery requirements, continuous and continuous dehumidification, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

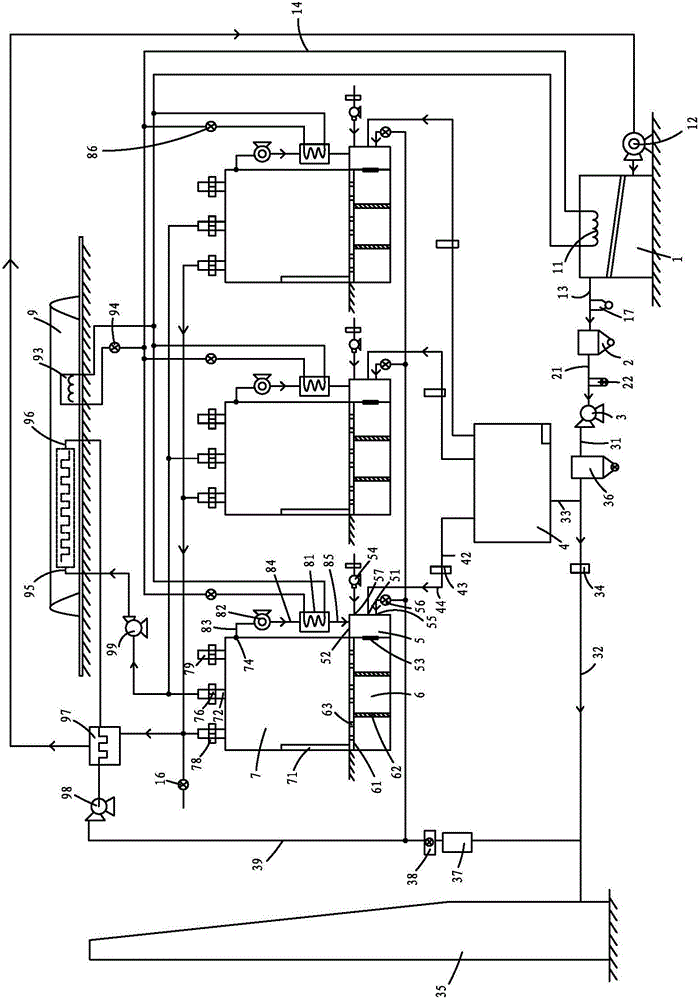

[0036] Such as figure 1 As shown, a drying kiln system for radiator and furnace gas mixed application includes an organic heat carrier furnace 1, a furnace gas discharge chimney 35, a multi-tube dust collector 2, a boiler induced draft fan 3, and a furnace gas buffer chamber 4. A plurality of drying room devices and a tunnel drying kiln 9;

[0037] The organic heat carrier furnace 1 has a steam generator 11 and a boiler blower 12; the steam generator 11 is connected to a heating pipeline 14, and the heating pipeline 14 is respectively connected to each drying room device; the furnace of the organic heat carrier furnace 1 The gas outlet is connected to the multi-tube dust collector 2; the boiler blower 12 is connected to a heat recovery device 97;

[0038] The multi-tube dust collector 2 is connected to the boiler induced draft fan 3;

[0039] The air pipe of the boiler induced draft fan 3 forms two branches, which are respectively connected to the furnace gas buffer chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com