Connection structure of pipe and flange and its processing method

A technology of connection structure and processing method, applied in the direction of flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of affecting eyes, affecting the life of operators, complex manufacturing process, etc., to avoid irritating gases and The effect of dazzling fire, avoiding the complicated process of the brazing furnace, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

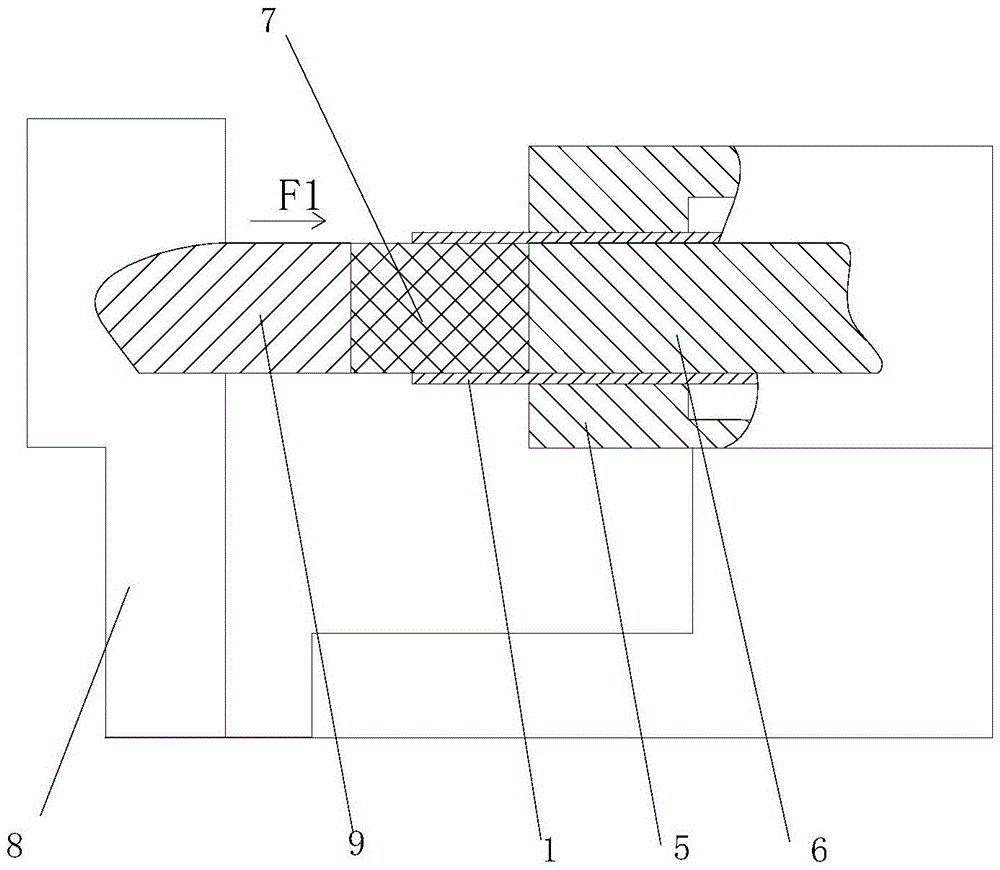

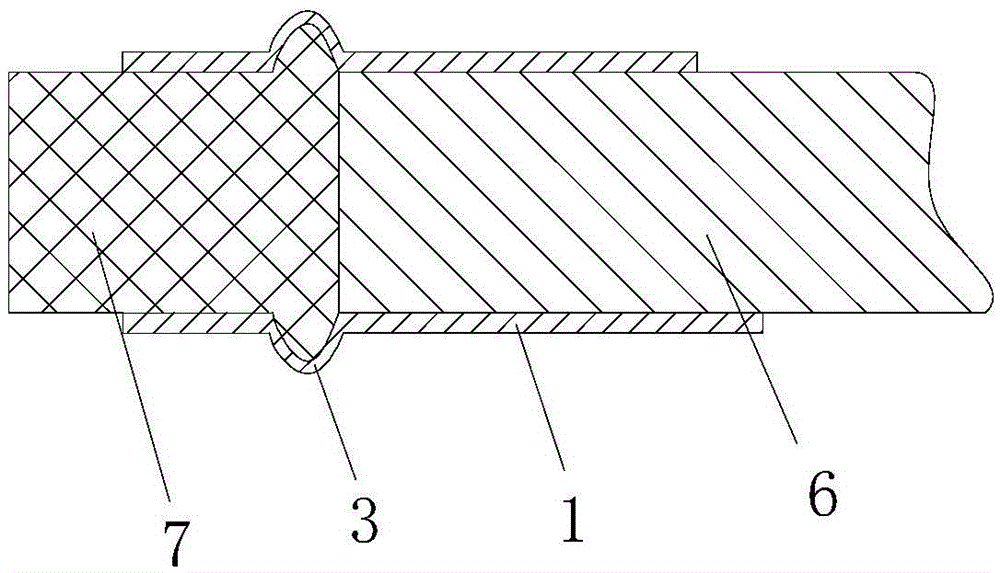

[0027] A connection structure between a pipe and a flange, which includes a pipe 1 and a flange 2 sleeved on the end of the pipe, the pipe 1 inside the flange 2 is a convex ring 3 that expands radially outward, and the pipe 1 outside the flange 2 The flange 2 is pressed against the flange 3 by the flange 4 which expands radially outwards. The protruding ring 3 looks like an annular bulge in the actual pipe fitting.

[0028] The flange 4 is also provided with a plurality of connecting holes for connecting with external pipe fittings.

[0029] A glass fiber mesh cloth is arranged between the outer wall of the flange 2 and the outer wall of the pipe 1, and a glass fiber mesh cloth is arranged between the outer wall of the flange 2 and the outer wall of the convex ring 3. Glass fiber mesh cloth has the advantages of alkali resistance, flexibility, and high warp and weft tensile strength, and also has the functions of heat preservation, crack resistance, and waterproof. Therefore,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com