Neodymium ion-doped scandium oxide lutetium oxide mixed crystal laser material and preparation method thereof

A kind of scandium oxide lutetium oxide, laser material technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

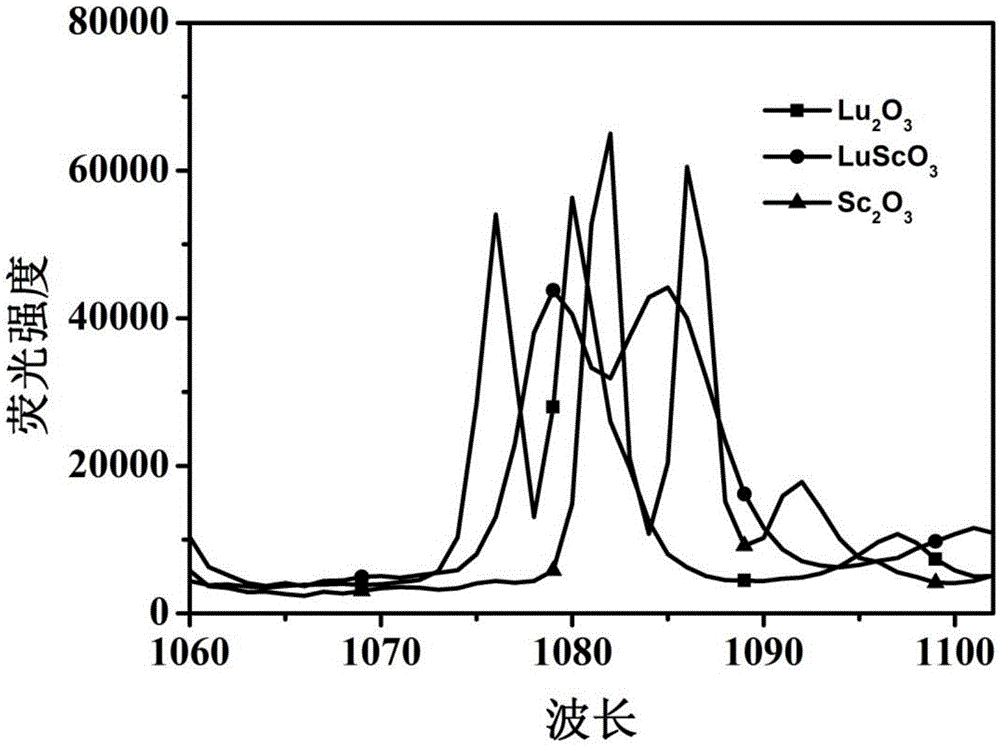

Embodiment 1

[0019] According to the molecular formula, the ratio of raw materials is prepared by hot isostatic pressing method to prepare Nd: LuScO 3 , get x=1 in the proportioning of raw materials. First, high-purity Lu 2 o 3 、Sc 2 o 3 、Nd 2 o 3 The powder is weighed according to the above ratio, mechanically mixed evenly, sieved through a 200-mesh sieve, weighed, put into a circular mold with a diameter of 40mm, and pressed under a pressure of 3kPa, and the prepared block is put into a vacuum sintering furnace Medium, evacuated to 9 x 10 -4 Pa, heated to 1600°C, and kept for 3 hours to obtain a sample with a density of 90%; put the obtained sample with a density of 90% into a hot isostatic pressing furnace, pressurize to 200 MPa under an Ar gas atmosphere, and heat to 1800℃, holding for 5h, get high quality Nd:LuScO 3 Mixed Crystal Laser Materials Using Prepared Nd:LuScO 3 Mixed crystal, polished coating, laser cavity design, using 808nmLD pump to obtain 1064nm laser output.

Embodiment 2

[0021] According to the molecular formula, the ratio of raw materials is prepared by hot isostatic pressing method to prepare Nd: LuScO 3 , get x=1 in the proportioning of raw materials. First, high-purity Lu 2 o 3 、Sc 2 o 3 、Nd 2 o 3 The powder is weighed according to the above ratio, and after mechanical mixing, it is sieved through a 250-mesh sieve and weighed, then put into a circular mold with a diameter of 60mm and pressed under a pressure of 6kPa, and the prepared block is put into a vacuum sintering furnace In, evacuate to 1 x 10 -3 Pa, heated to 1800° C., and kept for 10 hours to obtain a sample with a density of 98%; put the obtained sample with a density of 98% into a hot isostatic pressing furnace, pressurize to 300 MPa under an Ar gas atmosphere, and heat to 2000°C, hold for 20h, get high quality Nd:LuScO 3 Mixed Crystal Laser Materials Using Prepared Nd:LuScO 3 Mixed crystal, polished coating, laser cavity design, using 808nmLD pump to obtain 1064nm lase...

Embodiment 3

[0023] According to the molecular formula, the raw material ratio is prepared by hot isostatic pressing method to prepare Nd:Lu 1.9 sc 0.1 o 3 , get x=1 in the proportioning of raw materials. First, high-purity Lu 2 o 3 、Sc 2 o 3 、Nd 2 o 3 The powder is weighed according to the above-mentioned ratio, and after mechanical mixing, it is weighed through a 225-mesh sieve and put into a square mold with a length of 80mm and a width of 80mm and pressed under a pressure of 5.5kPa, and the prepared block is put into In the vacuum sintering furnace, vacuumize to 5×10 -4 Pa, heated to 1700°C, and kept for 6.5h to obtain a sample with a density of 95%; put the obtained sample with a density of 95% into a hot isostatic pressing furnace, pressurize to 250MPa under an Ar gas atmosphere, and heat To 1900 ℃, keep warm for 12.5h, get high quality Nd:LuScO 3 Mixed Crystal Laser Materials Using Prepared Nd:LuScO 3 Mixed crystal, polished coating, laser cavity design, using 808nmLD pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com