PbSe quantum dot doped sodium aluminum boron germanate glass optical fiber

A technology of borogermanic acid and quantum dots, which is applied in the direction of cladding optical fiber, glass manufacturing equipment, optical waveguide and light guide, etc., to achieve the effect of low cost, simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

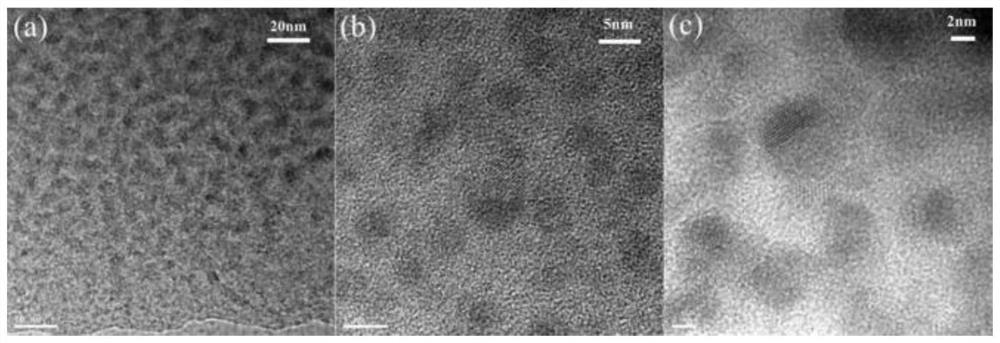

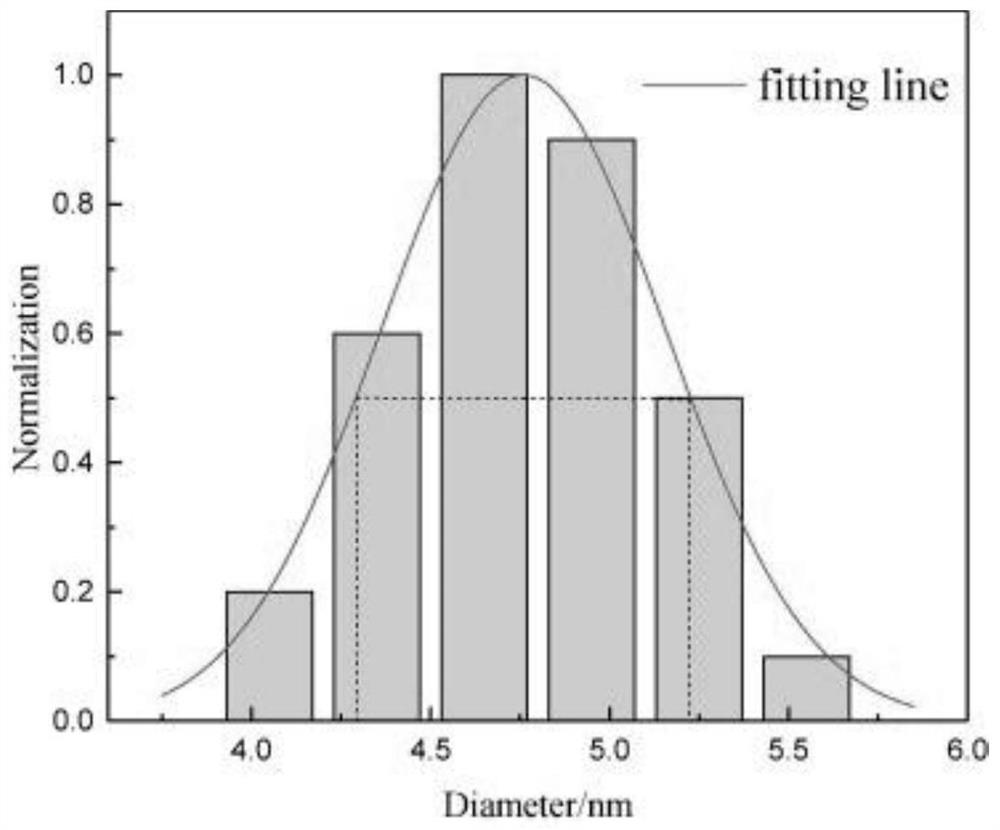

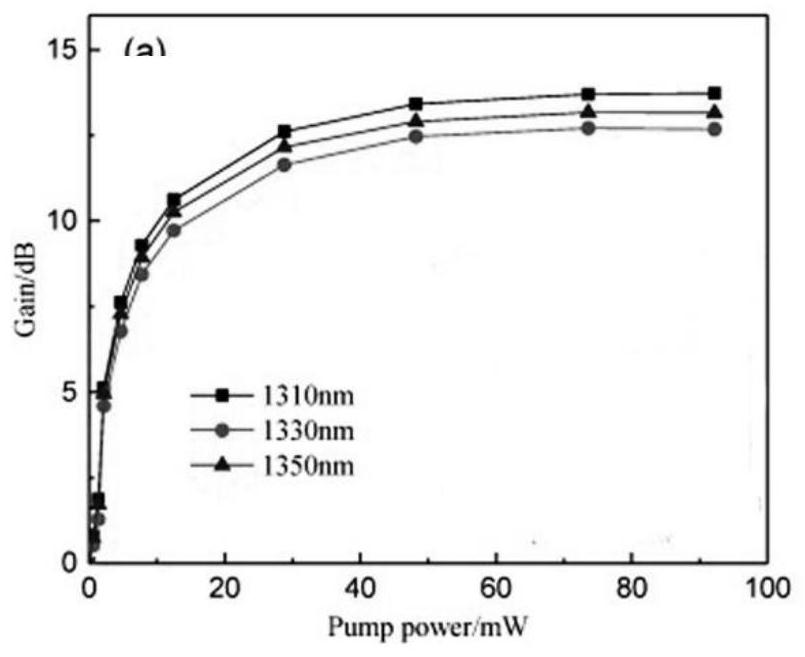

Image

Examples

Embodiment 1

[0030] The preparation process of a PBSE quantum doped soda-doped sodium aluminum boronylumide glass fiber includes the following steps:

[0031] 1) 52 GEOs 2 , 24 NA 2 CO 3 , 3 copies of Al 2 O 3 4 copies of B 2 O 3 , 8 copies of ZnO, 4 copies of ALF 3 · 3h 2 O, 5.8 parts of PBO, 3.2 copies of Znse sufficiently ground in ceramic mortar and stirred in a stirrer (750 T type) for about 5 minutes, stirring several times to make the mixture adequately homogeneously;

[0032] 2) Pour in step 1) into the corundum crucible and attached to the bumps (KSL1700X type) of the crucible, and the mixture is melted, and the melting temperature is 1300 ° C, wherein the melting temperature is 1300 ° C. Ice bath is cold.

[0033] 3) Put the molten mixture of cold collections into the box high temperature sinter, 750 ° C for 30 minutes;

[0034] 4) The wire extends into the melt, tensile vertically, then draws a glass fiber having a diameter of about 120 μm, and the heat tensile temperature is 420 ° ...

Embodiment 2

[0038] The preparation process of a PBSE quantum doped soda-doped sodium aluminum boronylumide glass fiber includes the following steps:

[0039] 1) 40 copies of GEO 2 18 copies of NA 2 CO 3 2 copies of Al 2 O 3 , 3 copies of B 2 O 3 , 6 copies of ZnO, 3 copies of ALF 3 · 3h 2 O, 5 parts of PBO, 3 copies of Znse sufficiently ground in ceramic mortar, and stirred in a stirrer (750 T type) for about 5 minutes, stirring several times to make the mixture adequately homogeneously;

[0040] 2) Pour in step 1) into the corundum crucible and attached to the bumps (KSL1700X type) of the crucible, and the mixture is melted, and the melting temperature is 1300 ° C, wherein the melting temperature is 1300 ° C. Ice bath is cold.

[0041] 3) Put the molten mixture of cold collections into the box high temperature sinter, 750 ° C for 30 minutes;

[0042] 4) The wire extends into the melt, tensile vertically, then draws a glass fiber having a diameter of about 120 μm, and the heat tensile tempera...

Embodiment 3

[0046] The preparation process of a PBSE quantum doped soda-doped sodium aluminum boronylumide glass fiber includes the following steps:

[0047] 1) 52 GEOs 2 , 24 NA 2 CO 3 , 3 copies of Al 2 O 3 4 copies of B 2 O 3 , 8 copies of ZnO, 4 copies of ALF 3 · 3h 2 O, 5.8 parts of PBO, 3.2 copies of Znse sufficiently ground in ceramic mortar and stirred in a stirrer (750 T type) for about 5 minutes, stirring several times to make the mixture adequately homogeneously;

[0048] 2) Pour in step 1) into the corundum crucible and attached to the bumps (KSL1700X type) of the crucible, and the mixture is melted, and the melting temperature is 1300 ° C, wherein the melting temperature is 1300 ° C. Ice bath is cold.

[0049] 3) Put the molten mixture of cold collections into the box high temperature sinter, 750 ° C for 30 minutes;

[0050] 4) The wire extends into the melt, tensile vertically, then draws a glass fiber having a diameter of about 120 μm, and the heat tensile temperature is 420 ° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com