Chemical grouting material for coal-rock mass water shutoff and reinforcement and preparation method thereof

A chemical grouting material and technology for coal and rock mass, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of unreinforced coal and rock mass, low strength, and inability to completely block water, etc., and achieve the price of raw materials. Inexpensive and easy to obtain, meet environmental protection requirements, excellent pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

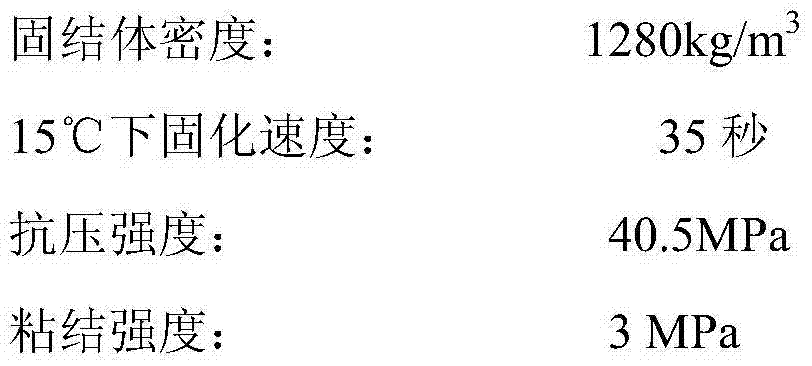

Image

Examples

Embodiment 1

[0036] Prepare 100 kg of A component material, weigh liquid sodium silicate (modulus 2.8, Baume degree 45, Yongqing County Julide Chemical Co., Ltd.) 70 kg, ethylene glycol (Sinopec Qilu Petrochemical Company) 29.5 kg, Catalyst (brand BDMAEE, Jiangdu Dajiang Chemical Industry Co., Ltd., Jiangsu Province) 0.5kg. Add the weighed ethylene glycol and catalyst into the reaction kettle and stir, stir and mix evenly at room temperature, then add liquid sodium silicate, stir evenly to obtain the qualified product of component A, discharge the material from the reaction kettle and put it into a barrel before putting it into the warehouse .

[0037] Prepare 100 kg of component B material, weigh polyphenyl polymethylene polyisocyanate (brand PM200, Yantai Wanhua Polyurethane Co., Ltd.) 70kg, viscosity reducer (brand DOP, Qingzhou Jianbang Chemical Co., Ltd.) 30kg respectively . Put the weighed polyphenyl polymethylene polyisocyanate and viscosity reducer into the reaction kettle and st...

Embodiment 2

[0041] Prepare 100 kg of A component material, respectively weigh liquid sodium silicate (modulus 2.8, Baume degree 45, Yongqing County Julide Chemical Co., Ltd.) 79.8kg, ethylene glycol (Sinopec Qilu Petrochemical Company) 20kg, Catalyst (brand Jeffcat ZR-70, American Huntsman Company) 0.2kg. Add the weighed ethylene glycol and catalyst into the reaction kettle and stir, stir and mix evenly at room temperature, then add liquid sodium silicate, stir evenly to obtain the qualified product of component A, discharge the material from the reaction kettle and put it into a barrel before putting it into the warehouse .

[0042] Prepare 100 kg of component B material, weigh polyphenyl polymethylene polyisocyanate (brand PM200, Yantai Wanhua Polyurethane Co., Ltd.) 80kg, viscosity reducer (brand DOP, Qingzhou Jianbang Chemical Co., Ltd.) 20kg respectively . Put the weighed polyphenyl polymethylene polyisocyanate and viscosity reducer into the reaction kettle and stir, stir and mix e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com