Formaldehyde-free defatted soybean flour-based adhesive for fiberboard and preparation method thereof

A defatted soybean flour and fiberboard technology, which is applied in the preparation of adhesives, animal glue or gelatin, and the types of adhesives, can solve problems such as formaldehyde pollution, save production costs, comprehensively utilize resources, and ensure the effect of bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Prepare materials according to the following weight:

[0048] Demineralized water 230 kg

[0050] Polyacrylamide 1kg

[0051] Defatted Soy Protein Powder 60 kg

[0052] Protein-ethylene oxide reactant 40 kg;

[0053] 2) Add sodium carbonate and defatted soybean protein powder into demineralized water in a reaction kettle equipped with a stirrer, thermometer and condensing device, and stir evenly;

[0054] 3) Heat the obtained mixture of sodium carbonate, defatted soybean protein powder and demineralized water to 42-46°C and keep it warm for 3 hours;

[0055] 4) Cool down the mixture obtained in the previous step to 35°C to obtain a uniform soy protein mucus;

[0056] 5) Add the protein-ethylene oxide reaction to the soy protein mucus obtained in the previous step, stir evenly, and then spray dry it into a powdery solid to make a soy protein adhesive for wood-based panels.

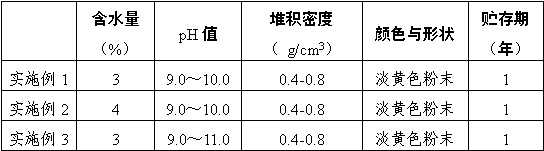

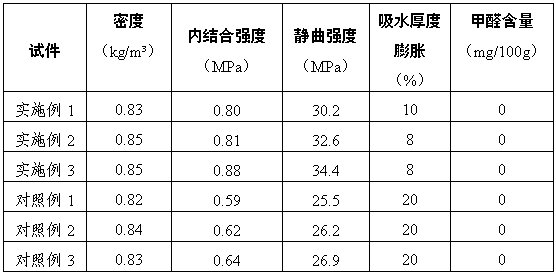

[0057] The performance and quality indicators of the obta...

Embodiment 2

[0059] 1) Prepare materials according to the following weight:

[0060] Demineralized water 240 kg

[0061] Sodium carbonate 2 kg

[0062] Polyacrylamide 2kg

[0063] Defatted Soy Protein Powder 58 kg

[0064] Protein-ethylene oxide reactant 42 kg;

[0065] 2) Add sodium carbonate and defatted soybean protein powder into demineralized water in a reaction kettle equipped with a stirrer, thermometer and condensing device, and stir evenly;

[0066] 3) Heat the obtained mixture of sodium carbonate, defatted soybean protein powder and demineralized water to 48-51°C and keep it warm for 4 hours;

[0067] 4) Cool down the mixture obtained in the previous step to 40°C to obtain a uniform soy protein mucus;

[0068] 5) Add the protein-ethylene oxide reaction to the soy protein mucus obtained in the previous step, stir evenly, and then spray dry it into a powdery solid to make a soy protein adhesive for wood-based panels.

[0069] The performance and quality indicators of the obta...

Embodiment 3

[0071] 1) Prepare materials according to the following weight:

[0072] Demineralized water 245 kg

[0073] Sodium carbonate 3 kg

[0074] Polyacrylamide 2.5kg

[0075] Defatted Soy Protein Powder 55 kg

[0076] Protein-ethylene oxide reactant 45 kg;

[0077] 2) Add sodium carbonate and defatted soybean protein powder into demineralized water in a reaction kettle equipped with a stirrer, thermometer and condensing device, and stir evenly;

[0078] 3) Heat the obtained mixture of sodium carbonate, defatted soybean protein powder and demineralized water to 58-60°C and keep it warm for 5 hours;

[0079] 4) Cool down the mixture obtained in the previous step to 45°C to obtain a uniform soy protein mucus;

[0080] 5) Add the protein-ethylene oxide reaction to the soy protein mucus obtained in the previous step, stir evenly, and then spray dry it into a powdery solid to make a soy protein adhesive for wood-based panels.

[0081] The performance and quality indicators of the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com