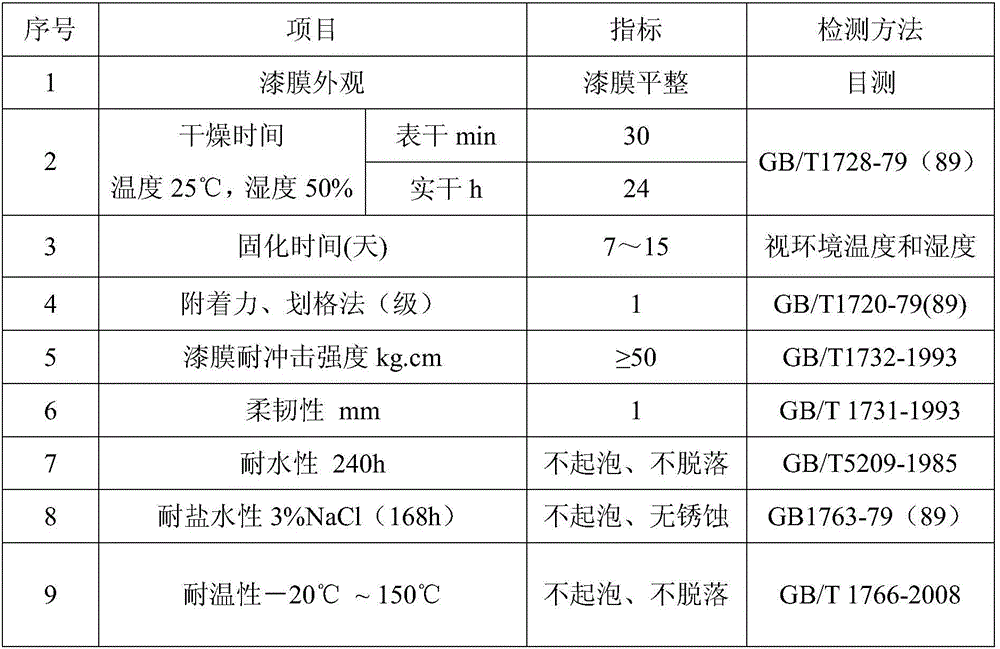

A kind of flexible wear-resistant hardware heavy-duty anti-corrosion coating and preparation method thereof

A heavy-duty anti-corrosion and coating technology, applied in anti-corrosion coatings, coatings and other directions, can solve the problem of not reaching the expected service life, and achieve the effect of facilitating on-site construction, simplifying the preparation process, and enhancing heavy-duty anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

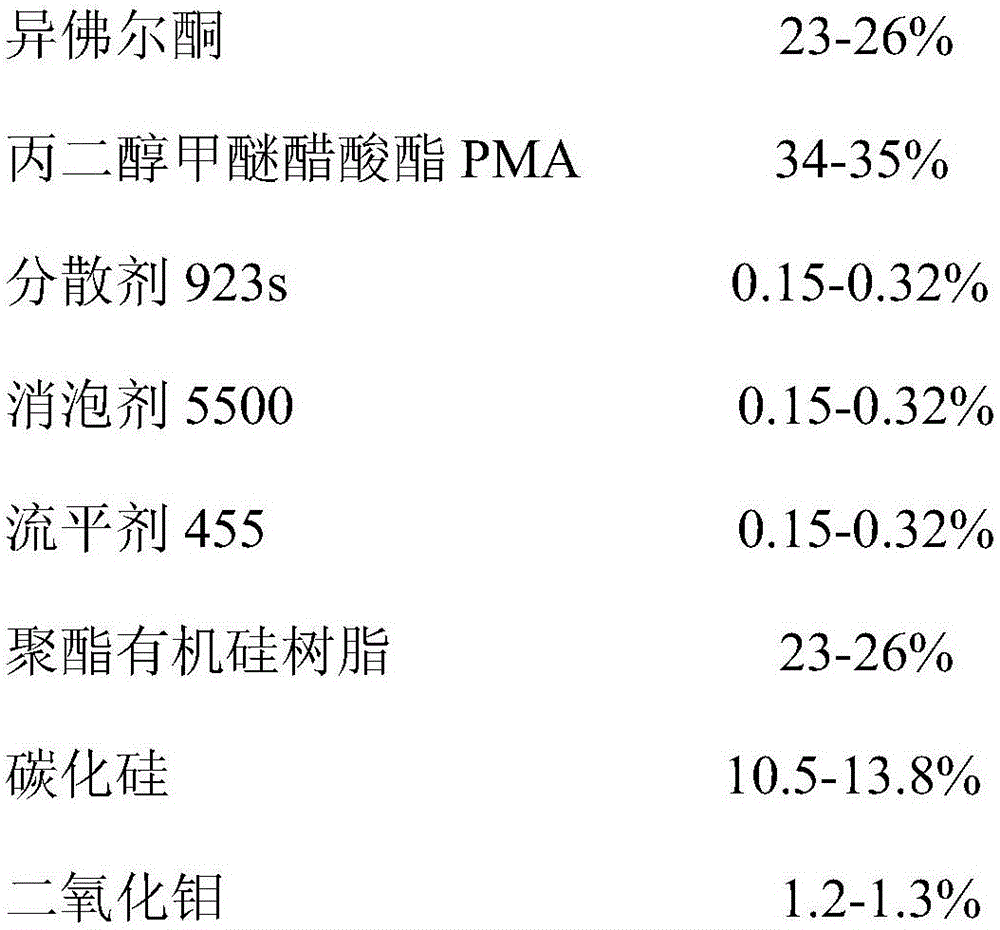

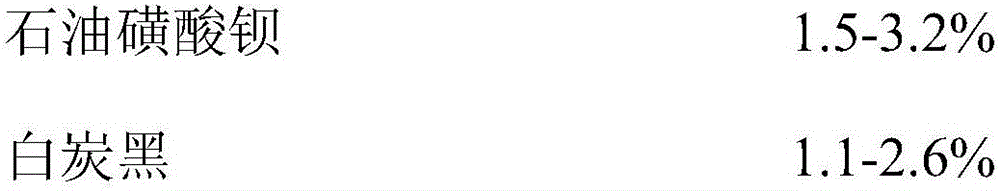

[0024] Embodiment 1, a kind of preparation method of heavy-duty anticorrosion paint of flexible wear-resistant metalware is characterized in that concrete steps are as follows: (1) according to the proportioning of component A, weigh 23% isophorone and 35% propylene glycol A Add ether acetate PMA to the dispersing device and stir evenly, add 0.25% by mass of dispersant 923s, 0.3% of defoamer 5500, and 0.2% of leveling agent 455, and continue to stir and mix evenly to form a dispersion;

[0025] (2) Add KR-5235 polyester silicone resin with a mass percentage of 24.5% to the dispersion in step (1) and disperse evenly at a speed of 800 to 1000 rpm;

[0026] (3) the silicon carbide that is 12% by mass percentage, the molybdenum dioxide that is 1.25% by mass percentage and the barium petroleum sulfonate that is 2% by mass percentage are added in the dispersion liquid of step (2) at 500-1000 rev / min Disperse at high speed for 30-60 minutes to make the slurry evenly dispersed;

[00...

Embodiment 2

[0030] Embodiment 2, a kind of preparation method of flexible wear-resistant metalware heavy-duty anticorrosion coating, it is characterized in that concrete steps are as follows: (1) according to the proportioning of component A, weigh 25% isophorone and 34.5% propylene glycol A Add ether acetate into the dispersing device and stir evenly, add 0.2% by mass percentage of dispersant 923s, 0.25% of defoamer 5500, and 0.3% of leveling agent 455, and continue to stir and mix evenly to form a dispersion;

[0031] (2) Add KR-5235 polyester silicone resin with a mass percentage of 23% to the dispersion in step (1) and disperse evenly at a speed of 800 to 1000 rpm;

[0032] (3) the silicon carbide that is 11% by mass percentage, the molybdenum dioxide that is 1.25% by mass percentage and the barium petroleum sulfonate that is 2.5% by mass percentage are added in the dispersion liquid of step (2) at 500-1000 rev / min Disperse at high speed for 30-60 minutes to make the slurry evenly dis...

Embodiment 3

[0036] Embodiment 3, a kind of preparation method of flexible wear-resistant metalware heavy-duty anticorrosion coating, it is characterized in that concrete steps are as follows: (1) according to the proportioning ratio of A component, weigh 26% isophorone and 34% propylene glycol A Add ether acetate into the dispersing device and stir evenly, add 0.3% by mass of dispersant 923s, 0.15% of defoamer 5500, and 0.15% of leveling agent 455, and continue to stir and mix evenly to form a dispersion;

[0037] (2) Add KR-5235 polyester silicone resin with a mass percentage of 23.5% to the dispersion in step (1) and disperse evenly at a speed of 800 to 1000 rpm;

[0038](3) adding 12% silicon carbide by mass, 1.3% molybdenum oxide by mass and 1.5% barium petroleum sulfonate in the dispersion of step (2) at a speed of 500-1000 rpm Disperse for 30-60 minutes to make the slurry evenly dispersed;

[0039] (4) adding the homogeneously dispersed slurry in the step (3) to a conical mill and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com