High-toughness and impact-resistant resin eyeglass and preparation method thereof

A resin lens and impact-resistant technology, applied in the field of high-toughness and impact-resistant resin lenses and their preparation, can solve the problems of poor toughness, poor chemical resistance, and increased manufacturing costs of resin lenses, so as to improve the toughness, impact resistance, and resistance to The effect of improved chemical performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

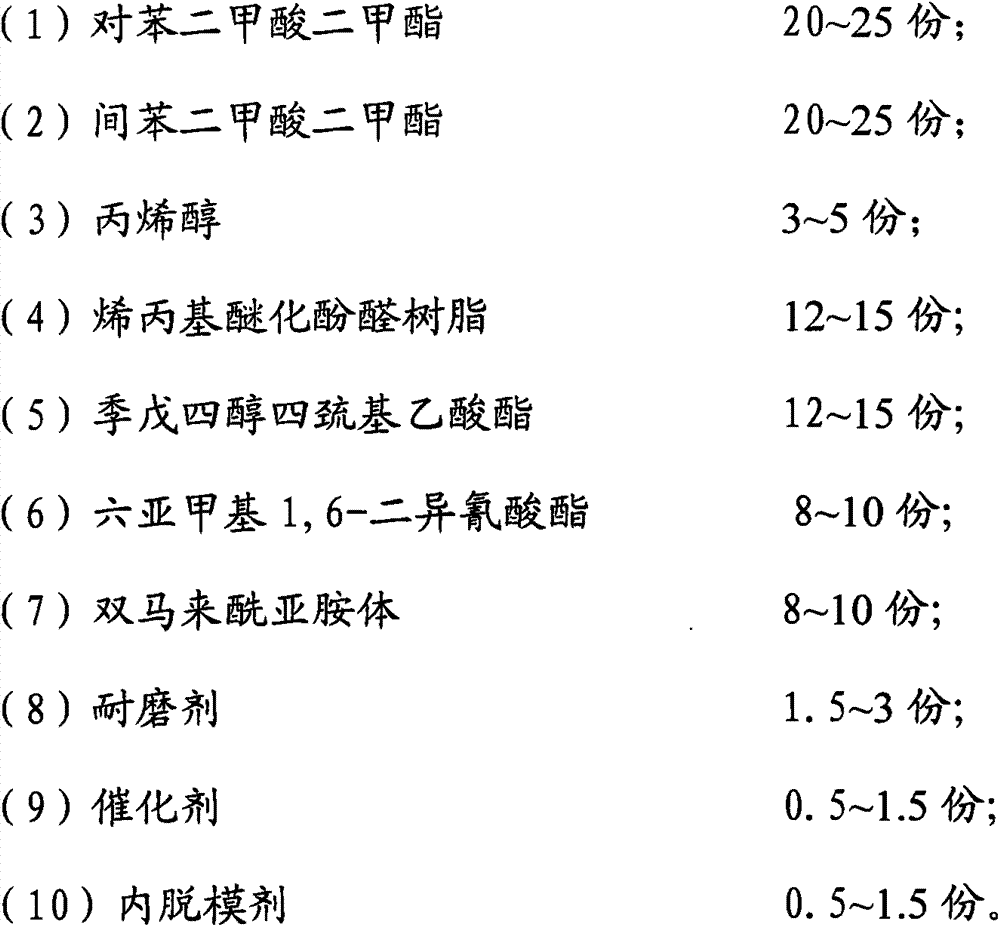

[0017] Prepare raw materials according to the following parts by weight:

[0018]

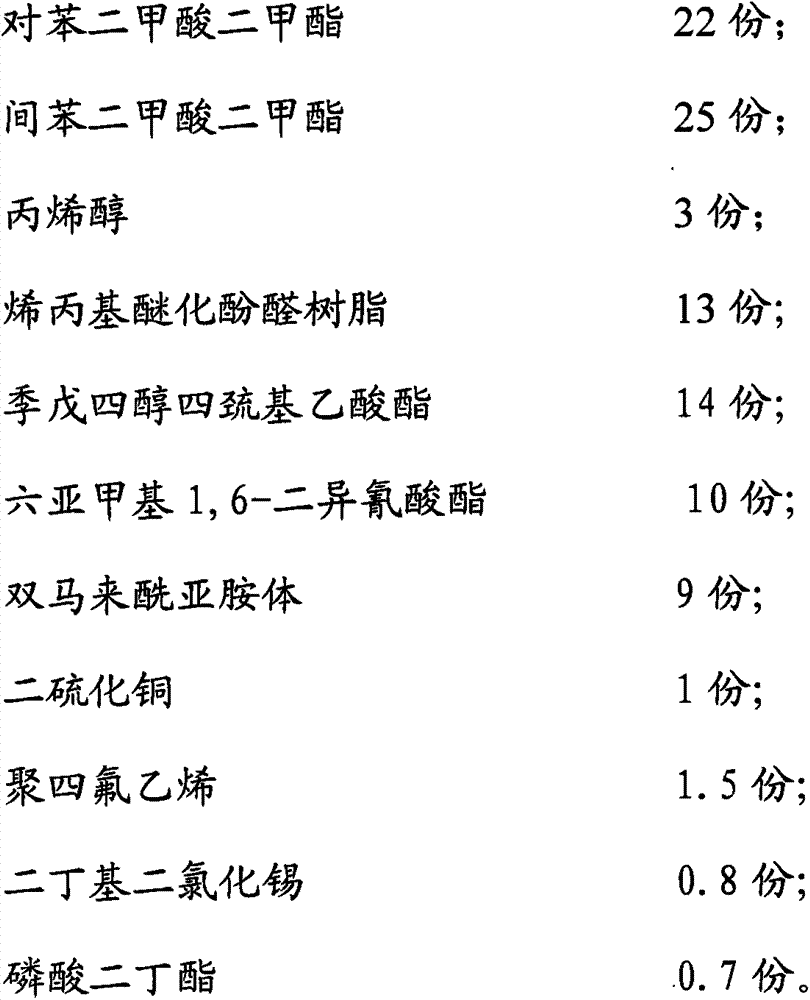

[0019] The corresponding preparation method: 1) Add dimethyl terephthalate, dimethyl isophthalate, and propenyl alcohol into the reactor according to the parts by weight prepared above, stir at 75°C for 5 hours, and then add the corresponding Add copper disulfide and polytetrafluoroethylene into the reactor, and continue to stir at 60°C for 2 hours to fully mix to form oligomers; 2) Then the oligomers formed in step 1 and allyl etherified phenolic resin , pentaerythritol tetramercaptoacetate, hexamethylene 1,6-diisocyanate, and bismaleimide were mixed at room temperature for 1 hour, and then dibutyl dichloride was added in sequence at a temperature of 20°C under vacuum. Tin and dibutyl phosphate continue to stir for 1.5 hours to form a mixture; 3) then the mixture obtained in step 2 is passed through a filter membrane with a pore size of 3 μm under the pressure of 0.1Mpa nitrogen to finally ...

Embodiment 2

[0021] Prepare raw materials according to the following parts by weight:

[0022]

[0023]

[0024] Corresponding preparation method: 1) Add dimethyl terephthalate, dimethyl isophthalate, and allyl alcohol into the reactor according to the parts by weight prepared above, stir at 70° C. for 4 hours, and then add the corresponding Add copper disulfide and polytetrafluoroethylene into the reactor, and continue to stir at 70°C for 1.5 hours to fully mix to form an oligomer; 2) Then the oligomer formed in step 1 and allyl etherified phenolic resin , pentaerythritol tetramercaptoacetate, hexamethylene 1,6-diisocyanate, and bismaleimide were mixed at room temperature for 1 hour, and then dibutyl dichloride was added in sequence at a temperature of 20°C under vacuum. Tin and dibutyl phosphate continue to stir for 1.5 hours to form a mixture; 3 amines to pass the mixture obtained in step 2 under the pressure of 0.08Mpa nitrogen, and pass through a filter membrane with a pore size...

Embodiment 3

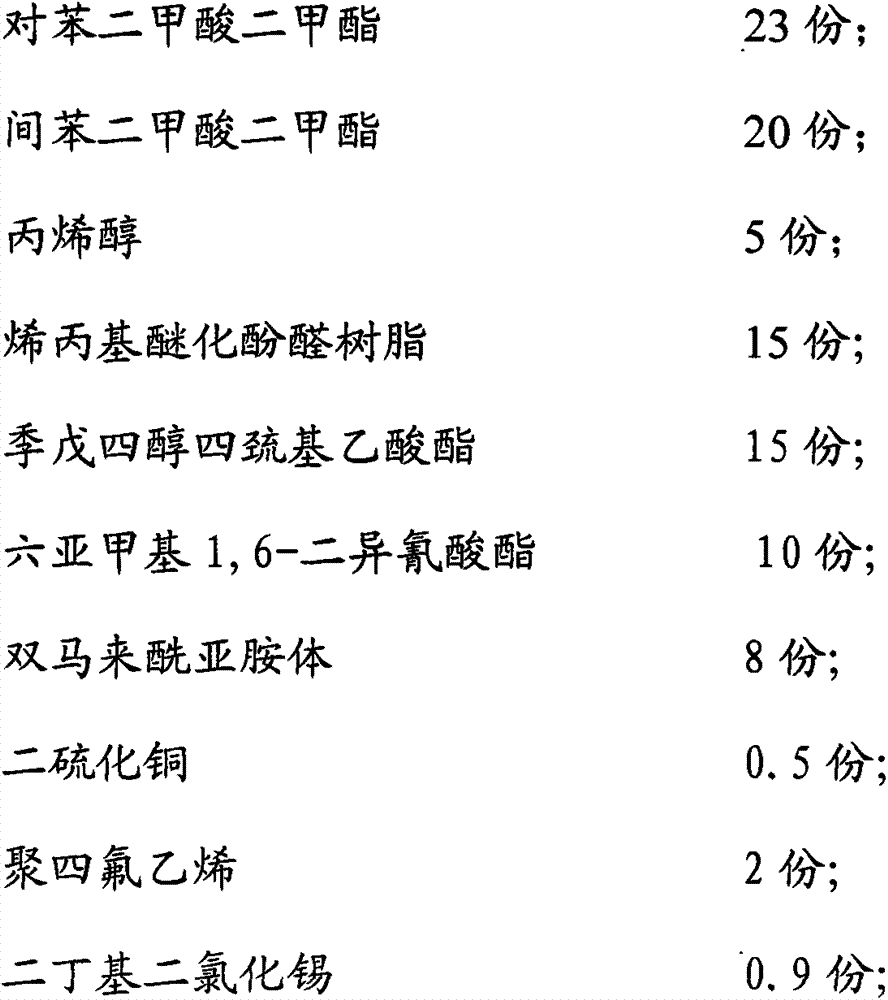

[0026] Prepare raw materials according to the following parts by weight:

[0027]

[0028]

[0029] Corresponding preparation method: 1) Add dimethyl terephthalate, dimethyl isophthalate, and allyl alcohol into the reactor according to the parts by weight prepared above, stir at 65° C. for 5 hours, and then add the corresponding Add copper disulfide and polytetrafluoroethylene into the reactor, and continue to stir at 80°C for 1.5 hours to fully mix to form an oligomer; 2) Then the oligomer formed in step 1 and allyl etherified phenolic resin , pentaerythritol tetramercaptoacetate, hexamethylene 1,6-diisocyanate, and bismaleimide were mixed at room temperature for 0.8 hours, and then dibutyl dichloride was added sequentially at a temperature of 20°C under vacuum. Tin and dibutyl phosphate continue to stir for 1.5 hours to form a mixture; 3) then the mixture obtained in step 2 is passed through a filter membrane with a pore size of 3 μm under the pressure of 0.08Mpa nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com