Polymerizable composition, optical material and manufacturing method for same

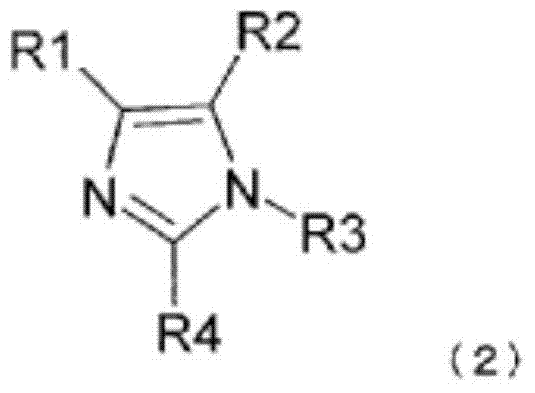

A technology of polymeric composition and compound, which is applied in optics, optical elements, optical parts, etc., can solve the problems of using imidazoles that have not been specifically disclosed, and achieve the effect of excellent optical physical properties and striae suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] 2.00 g of catalyst 1,2-dimethylimidazole was added to 8.00 g of internal mold release agent Zelec UN (acid phosphate: registered trademark, manufactured by Stepan Co., Ltd.), and mixed and dissolved at room temperature until a uniform solution was obtained to prepare a catalyst / release agent. Molding agent masterbatch liquid. Add 49.50 g of bis(4-isocyanatocyclohexyl)methane, 8.74 g of 2,5(6)-bis(isocyanatomethyl)-bicyclo[2.2.1]heptane, and further add 1.50 g of Biosorb 583 as an ultraviolet absorber and 0.18 g of the previously prepared catalyst / release agent masterbatch liquid were mixed and dissolved at 20°C. After dissolution, add 37.59 g of 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane and 4.17 g of diethylene glycol dimercaptopropionate, and mix and dissolve at 20°C , to make a homogeneous solution. This homogeneous solution was defoamed at 150 Pa for 30 minutes, filtered with a 1 μm Teflon (registered trademark) filter, and poured into a mold formed of a gla...

Embodiment 2

[0168] 3.33 g of the catalyst 1-benzyl-2-methylimidazole was added to 6.67 g of the internal mold release agent Zelec UN, and mixed and dissolved at room temperature until a uniform solution was obtained to prepare a catalyst / release agent masterbatch liquid. Add 49.50 g of bis(4-isocyanatocyclohexyl)methane and 8.74 g of 2,5(6)-bis(isocyanatomethyl)-bicyclo[2.2.1]heptane, and further add 1.50 g Biosorb 583 as an ultraviolet absorber and 0.15 g of the previously prepared catalyst / release agent masterbatch liquid were mixed and dissolved at 20° C., except that the same method as that described in Example 1 was used. Polymerized, a lens was obtained. The performance evaluation of the obtained lenses is summarized in Table-1.

Embodiment 3

[0170] Add 1.00 g of catalyst 1,2-dimethylimidazole and 1.66 g of 1-benzyl-2-methylimidazole to the internal release agent Zelec UN7.34 g, mix and dissolve at room temperature until it becomes a uniform solution, and prepare catalyst / Release agent masterbatch liquid. Add 49.50 g of bis(4-isocyanatocyclohexyl)methane and 8.74 g of 2,5(6)-bis(isocyanatomethyl)-bicyclo[2.2.1]heptane, and further add 1.50 g Biosorb 583 as an ultraviolet absorber and 0.25 g of the previously prepared catalyst / release agent masterbatch liquid were mixed and dissolved at 20° C., except that the same method as that described in Example 1 was used. Polymerized, a lens was obtained. The performance evaluation of the obtained lenses is summarized in Table-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com