Process for producing titanium tetrachloride in fluidizing chlorination furnace by using artificial rutile

A technology of artificial rutile and boiling chlorination furnace, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problems of artificial rutile with many micropores, not easy to fluidize, and surging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

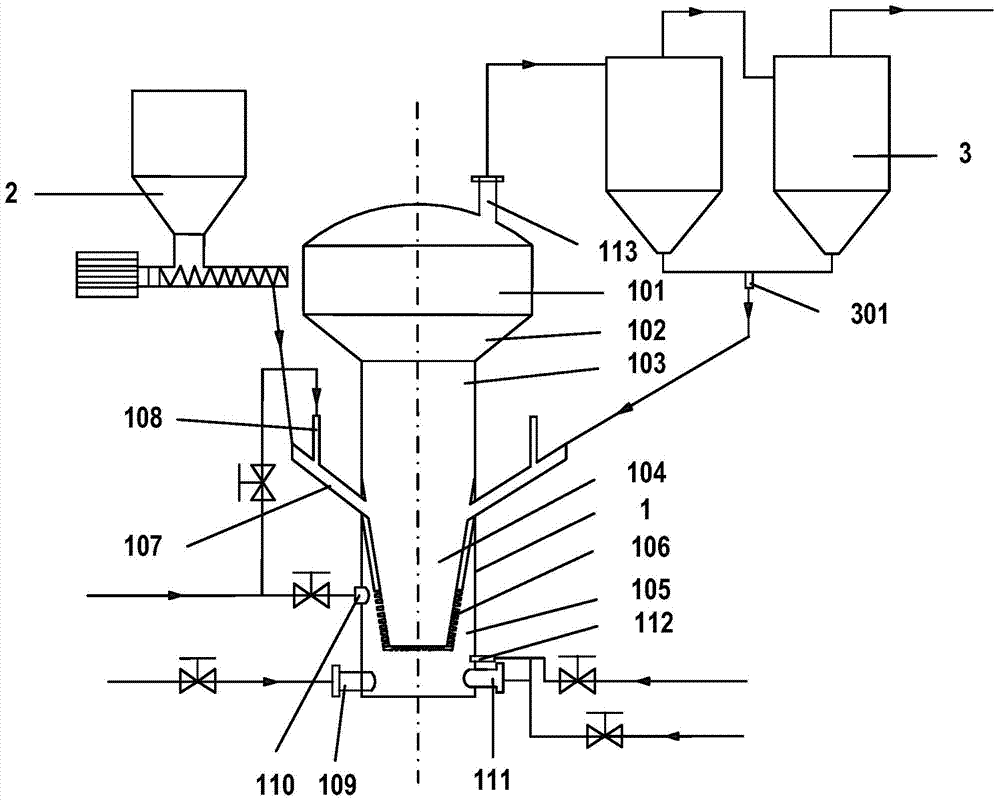

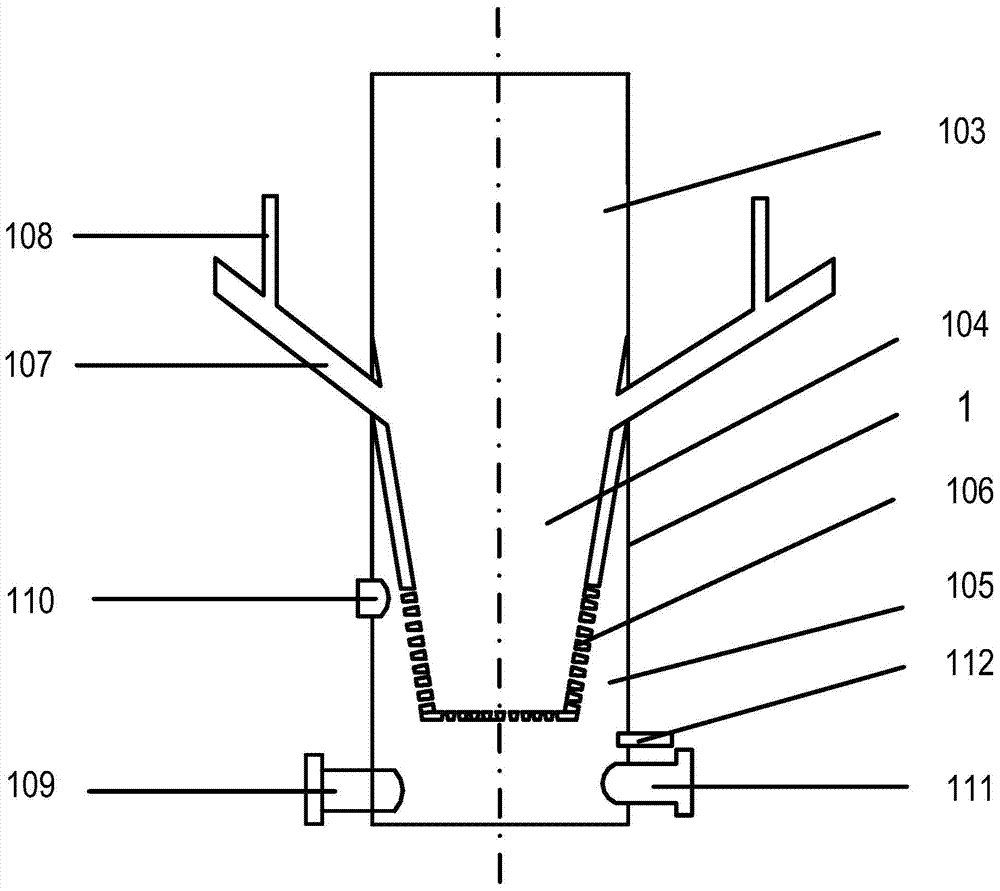

[0082] The fluidized chlorination furnace 1 adopted in the present embodiment is a regenerated fluidized chlorination furnace 1 through a lining refractory material, and the fuel gas is coal gas.

[0083] Open the air pipe valve and gas pipe valve in turn, light the burner 112, control the temperature of the gas premixing chamber 105 at 100-150°C, control the ratio of air and gas at 4:1, and bake the fluidized chlorination furnace 1.

[0084] According to the requirement of lining refractory material of boiling chlorination furnace 1, adjust the gas flow rate and gradually increase the gas temperature. When the gas temperature exceeds 500°C, increase the opening of the air pipe valve and increase the air flow rate. The total air volume is controlled at 300Nm3 / h. Gradually open the feeding screw of feeding system 2, add petroleum coke to the petroleum coke feeding pipe, open the nitrogen gas supply pipe valve connected with the gas purging pipe 108, inject nitrogen into the gas ...

Embodiment 2

[0092] The fluidized chlorination furnace 1 used in this embodiment was interrupted due to equipment failure. After the failure was quickly eliminated, the temperature in the furnace was relatively high.

[0093] Open the air pipe valve and gas pipe valve in turn, light the burner 112, control the temperature of the gas premixing chamber 105 at 300-450°C, control the ratio of air and gas at 4:1, and quickly bake the fluidized chlorination furnace 1.

[0094] When the gas temperature exceeds 500°C, increase the opening of the air pipe valve, increase the air flow, control the total air volume at 300Nm3 / h, gradually open the feeding screw of the feeding system 2, add petroleum coke to the petroleum coke feeding pipe, open and blow the gas The sweeping pipe 108 is connected to the nitrogen gas supply pipe valve, inject nitrogen gas into the gas purging pipe 108, use nitrogen gas to purge the petroleum coke in the trumpet-shaped structure part of the petroleum coke feeding pipe, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com