Annular pipe fitting flattening and forming die

A technology for forming molds and annular pipe fittings, which is applied in the field of flattening and forming molds for annular pipe fittings, can solve the problems of increased equipment consumption, low material utilization rate, and a large number of presses used in stamping production lines, so as to save the cost of mold manufacturing and the number of mold processes. The effect of reducing and reducing waste of human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

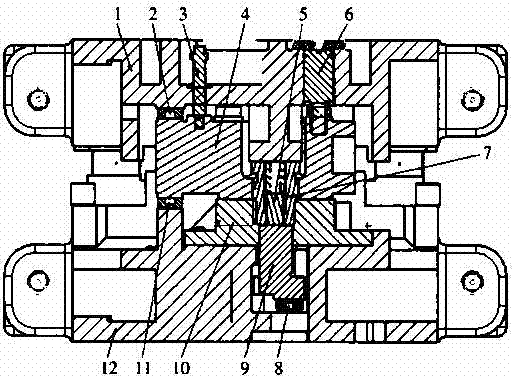

[0011] Such as figure 1 As shown, the present invention provides a ring-shaped pipe fitting flattening mold, including an upper mold base 1 and an upper mold base 12, and the upper mold base 1 is provided with an upper adjusting pad 2, a screw 3, an upper blank holder 4, Upper pressing block 5, nitrogen spring assembly 6 and upper die forming insert 7, said upper die forming insert 7 is located in the middle of said upper die base 1, said upper pressing block 5 is arranged on said upper die forming In the middle of the insert 7, the upper blank holder 4 is arranged on the left side of the upper mold forming insert 7 and fixed on the upper mold base 1 by screws 3, and the upper adjustment block 2 is arranged on the upper The upper left side of the die forming insert 7, the nitrogen spring assembly 6 is arranged on the upper right side of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com