Low-temperature-rise great-thrust direct current electromagnet

A DC electromagnet, high thrust technology, applied in the field of electromagnets, low temperature rise and high thrust DC electromagnets, can solve the problems of large starting thrust, temperature rise, large current, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the device and do not limit the scope of the present invention.

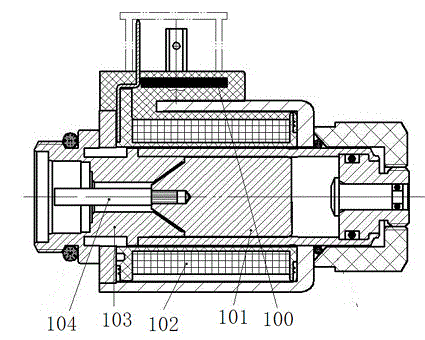

[0015] as attached figure 1 as shown, figure 1The control circuit of the present invention is formed between the power supply input and the coil. A low-temperature high-thrust DC electromagnet, including a DC power input terminal, a coil, an armature, and an iron core. After the DC input terminal is first connected to a bridge rectifier circuit, the positive pole is connected to the input pole of the coil, the output pole of the coil and the power supply. A MOS field effect transistor is connected between the negative poles, the emitter of the triode Q1 is connected to the positive pole of the power supply, the collector of the triode Q1 is connected to the gate of the MOS field effect transistor, and the base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bottom corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com