All-weather low-frequency acoustic sensor

A low-frequency sound wave and sensor technology, which is applied in the field of all-weather low-frequency sound wave sensors, to achieve the effects of improved sensitivity, strong anti-electromagnetic interference ability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

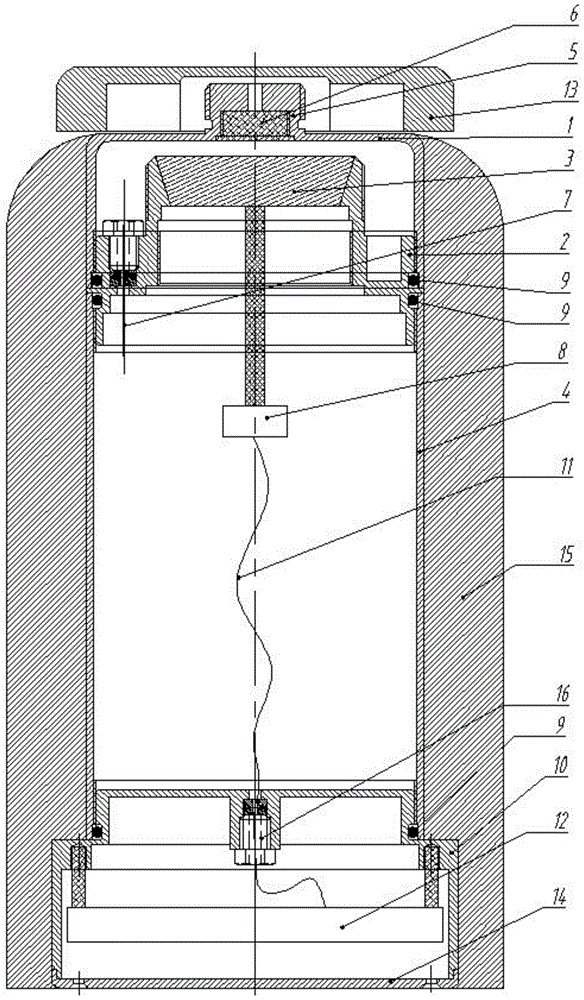

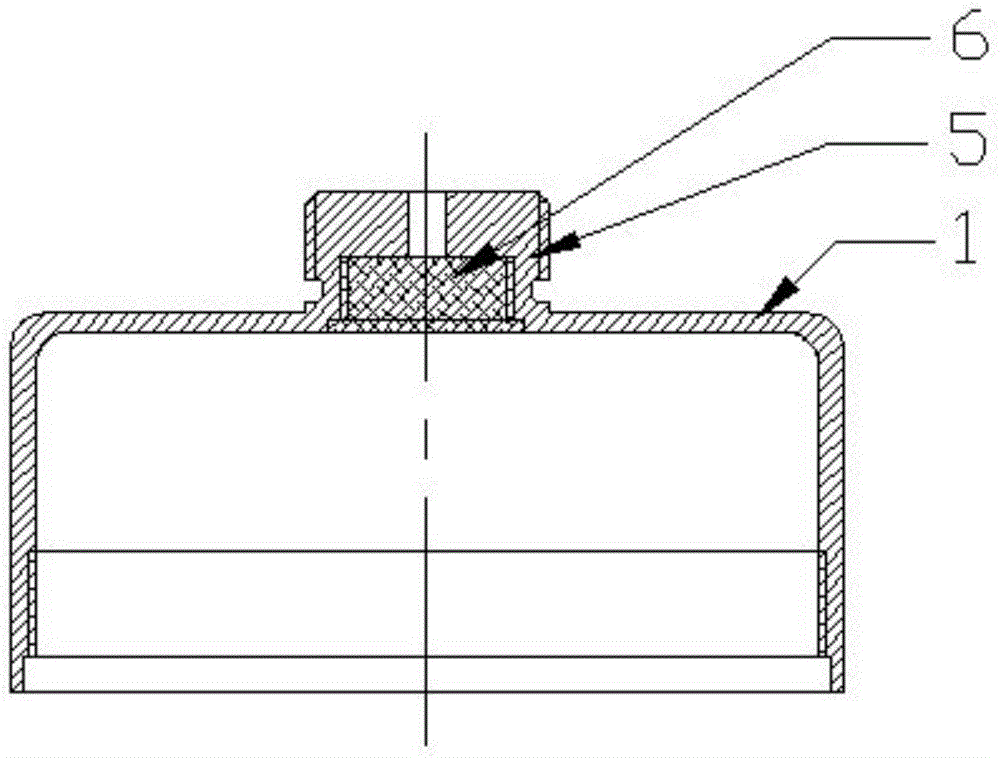

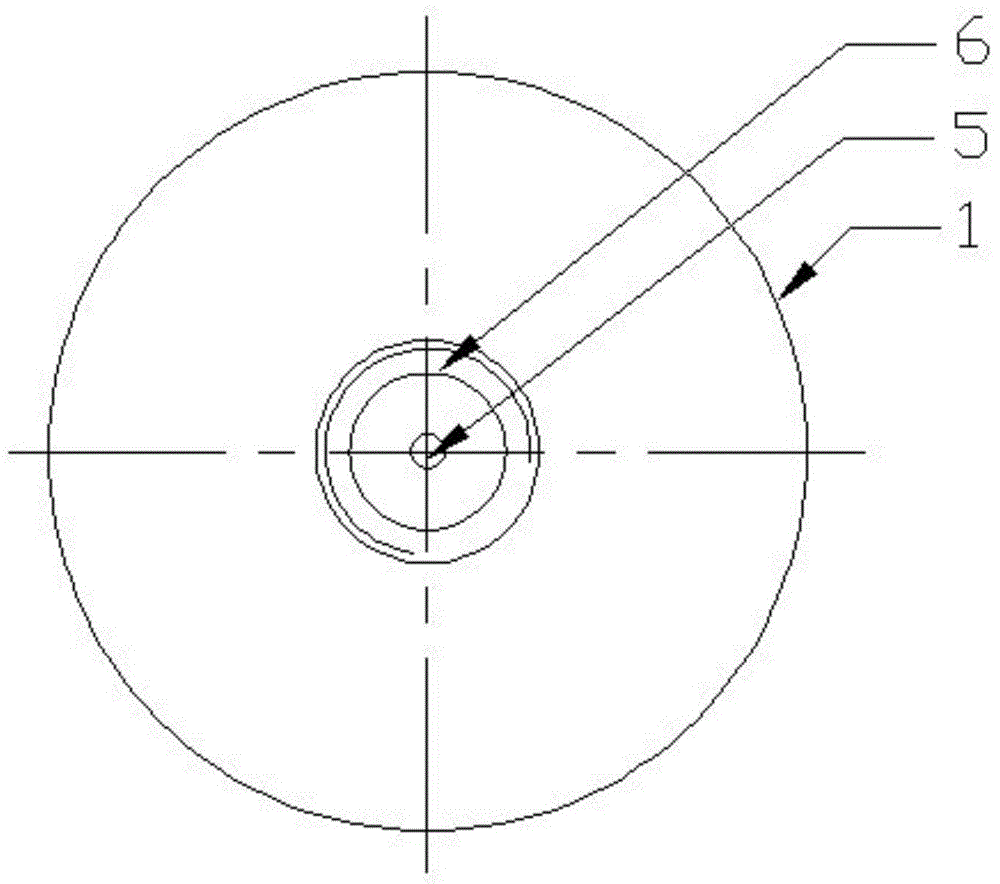

[0035] An all-weather low frequency acoustic wave sensor such as figure 1 As shown, it comprises anterior chamber 1, rear chamber pipe 4, preamplifier base 10 and heat insulation and anti-vibration cover 15, and described front chamber 1, rear chamber pipe 4 constitute sensor cavity. The inside of the front chamber 1 is threadedly connected with the main body 2, and a sealing O-ring 9-1 is arranged between the front chamber 1 and the main body 2 to prevent air leakage. The main body 2 is a rigid piece of stainless steel, and a sensitive head 3 is installed in the upper part of it. In order to enhance stability, the sensitive head 3 is locked after being installed and coated with anti-loosening glue. The sensitive head 3 is a high The sensitive sensitive element is made of non-magnetic metal material with good flexibility and not easily deformed; There is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com