Tunnel smooth blasting method

A smooth blasting and tunneling technology, applied in blasting and other directions, can solve problems such as delaying construction time, high explosive consumption, and reducing half-eye rate, etc., and achieve the effects of less explosive consumption, controllable footage, and high half-eye rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

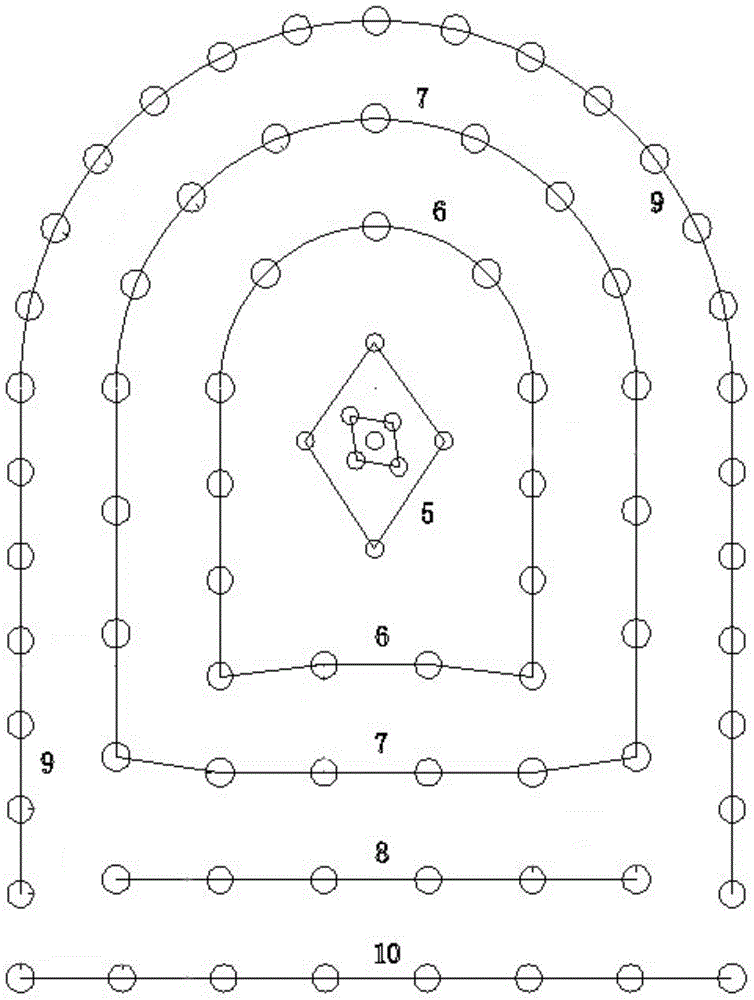

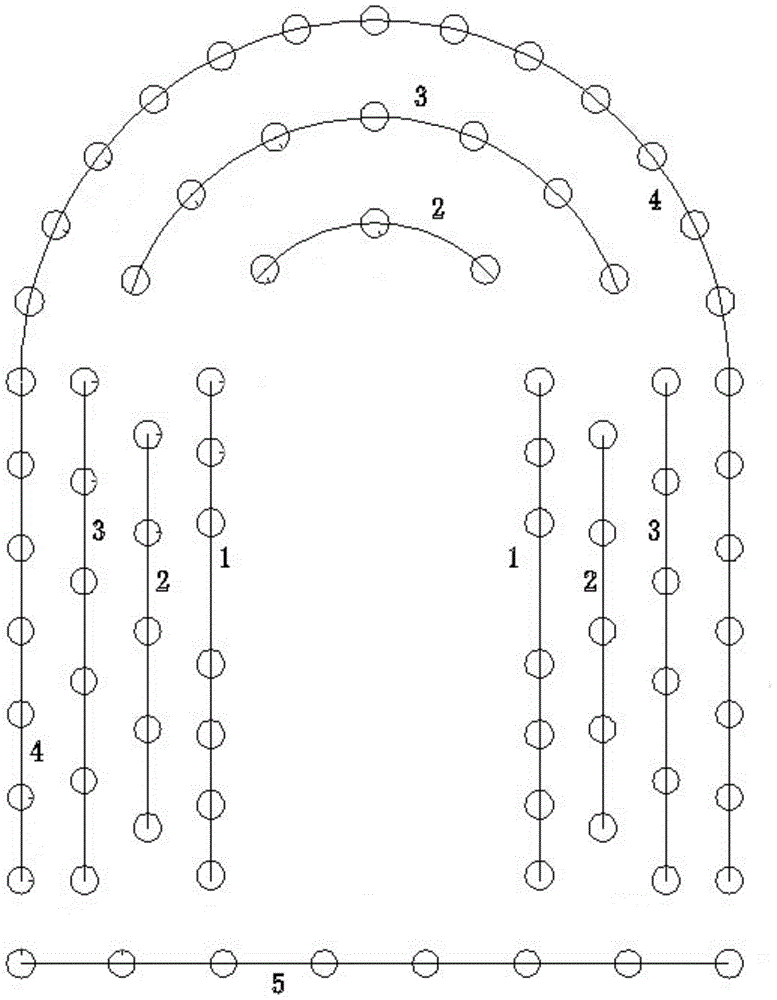

[0032] This embodiment takes the smooth blasting of the construction of the Shushui East Diversion Tunnel in Rizhao City, Shandong Province as an example. There are rivers diverting water to Rizhao Reservoir to realize the rational allocation of regional water resources and solve the problem of water shortage in Rizhao City. The total length of the water conveyance tunnel is 18.368km, the design flow rate is 10m3 / s, and the non-pressure flow is adopted. The tunnel is a city gate type. The excavation section is 4.1×3.3m plus a semi-circular arch. The cross-sectional area is 20.13m2, and the diameter of the semi-circular arch is 4.1m. The central angle is 180°, and the tunnel bottom gradient is 1 / 2854. Type II and III surrounding rocks are supported by bolts, hanging net sprayed concrete, and Type IV and V surrounding rocks are supported by steel frames, anchor bolts, hanging net sprayed concrete + reinforced concrete lining.

[0033] The surface terrain of the tunnel is quite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com