Mechanical connection type engine integration rocker arm brake device with valve lift reset function

A technology of mechanical connection and braking device, applied in the direction of engine control, machine/engine, valve device, etc., can solve the problems of high manufacturing and assembly cost, non-functioning, asymmetrical load, etc., to improve accuracy and stability , Shorten the stroke of the brake oil circuit and improve the effect of the layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

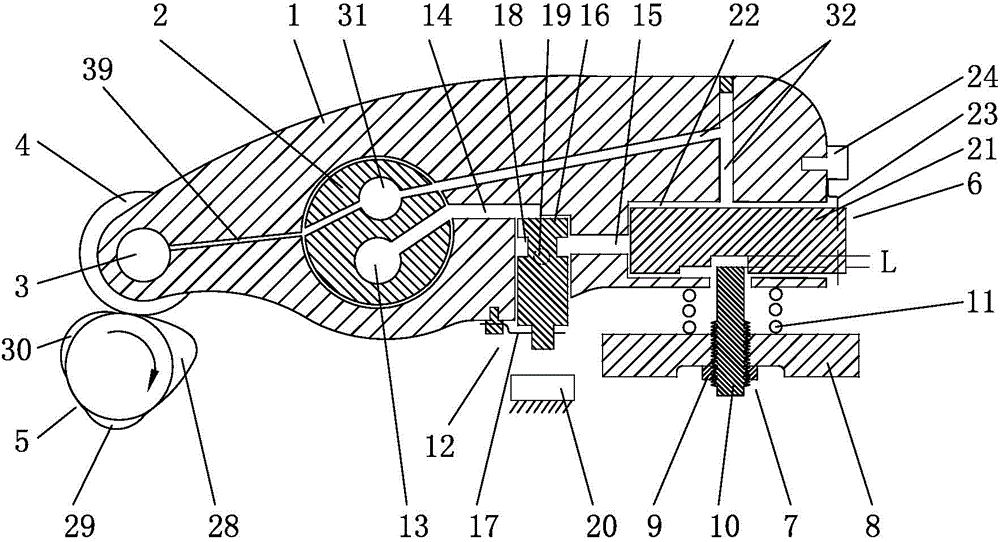

[0033] Embodiment 1: see figure 1 —4:

[0034]Mechanically connected engine integrated rocker arm brake device with valve lift reset, rocker arm 1 is set on the rocker arm shaft 2, one end of rocker arm 1 is provided with a roller 4 through a pin 3, the pin 3 is a copper pin, and the roller 4 is in contact with the exhaust cam 5, and the other end of the rocker arm 1 is provided with a brake mechanism 6, and an exhaust valve bridge 7 is arranged under the brake mechanism 6, and the brake mechanism 6 controls the action of the exhaust valve bridge 7, and the A control mechanism 12 is installed on the rocker arm 1 between the moving mechanism 6 and the rocker arm shaft 2. The rocker arm shaft 2 is provided with a brake oil passage 13 connected with the oil pump, and the power oil is controlled by the solenoid valve signal. Input, the rocker arm 1 is provided with the first brake oil passage 14 communicating with the control mechanism, and the second brake oil passage 15 communi...

Embodiment 2

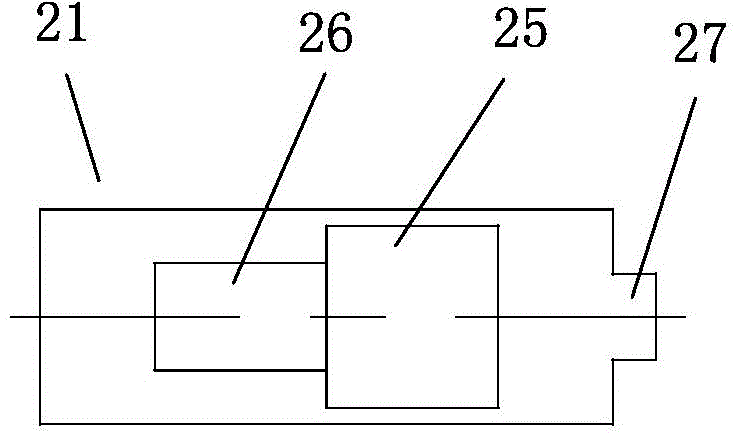

[0050] Example 2: see Figure 5 -8:

[0051] The difference between this embodiment and embodiment 1 lies in the difference of the braking mechanism:

[0052] The concrete structure of brake mechanism 6 is: comprise brake slider 31 and brake piston 32, the axes of brake slider 31 and brake piston 32 are perpendicular to each other, and brake slider 31 and brake piston 32 respectively pass spring plate 33 and 34 are installed on the rocker arm 1, a curved groove 35 is provided on the outer cylindrical surface of the brake slider 31, and an arc-shaped protrusion 36 is provided on the upper part of the brake piston 32, and the groove 35 and the protrusion 36 cooperates to make the brake piston 32 easy to slide in and out of the groove 35. The inside of the brake slider 31 is provided with a radially penetrating oil passage and an axial oil passage to form a T-shaped oil passage 37. One end of the axial oil passage communicates with the radial oil passage, and the other end runs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com