Method for determining setting depth of heating cable passing hollow sucker rod

A hollow sucker rod and heating cable technology, which is used in earthwork drilling, isolation devices, measurement and other directions, can solve the problems of difficult lifting, reduce oil pumping load, and high energy consumption, save production and operation costs, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

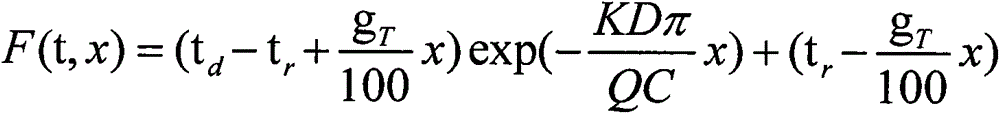

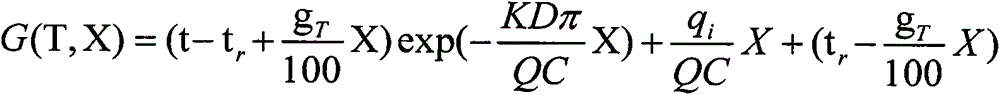

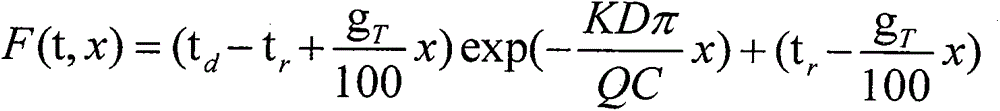

Method used

Image

Examples

Embodiment Construction

[0057] Taking well Yan 63-159 as an example to determine the running depth of the heating cable through the hollow sucker rod, it will be described in detail.

[0058] Physical properties of crude oil in Well Yan 63-159: density at 20°C, 0.932g / cm3, viscosity at 50°C 956.4mPa.s, freezing point 37°C, wax content 31.8%, well depth 2995.7m, daily oil production 12t / d, daily production 13t / d , The parameters of the lower pump are φ38mmx1929.28m.

[0059]Step 1. Collect the oil well parameters to be lowered into the hollow sucker rod, the technical parameters of the hollow sucker rod and the technical parameters of the heating cable:

[0060] 1. Oil pipe outer diameter D, 73mm;

[0061] 2. Crude oil pour point temperature t, 37°C;

[0062] 3. Wellhead oil outlet temperature T 井口 , 40°C;

[0063] 4. Oil production Q of oil well o , 12t / d;

[0064] 5. Oil well water production Q w , 13t / d;

[0065] 6. Geothermal gradient g T , 3°C / 100m;

[0066] 7. Reservoir temperature t, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com