Solution for electrochemical deburring and oxide layer removal of tantalum-foil material primary emitter for magnetron and deburring method

An emitter and deburring technology, applied in the field of electrolyte, can solve the problems of inability to electrolytically remove, reduce the accuracy of emitters, and fail to meet the working requirements of high precision and high performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

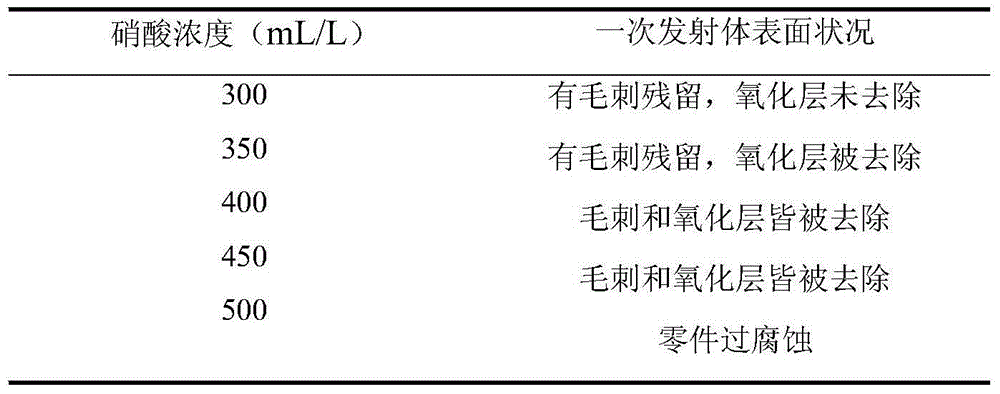

Embodiment 1

[0076] A method for electrolytic deburring and oxide layer removal of a tantalum foil material primary emitter for a magnetron, comprising the following steps:

[0077] (1) Take nitric acid, hydrofluoric acid, phosphoric acid, glycerol and sodium lauryl sulfate respectively, and prepare nitric acid 400mL / L, hydrofluoric acid 16mL / L, phosphoric acid 70mL / L, glycerin: 10mL with purified water / L, sodium lauryl sulfate: 0.3g / L electrolytic solution.

[0078] Then pour the prepared electrolytic deburring and oxide layer solution into the graphite container, and connect the graphite container to the positive pole of the rectifier;

[0079] (2) Wear and fix the primary emitter of the tantalum foil material used for the magnetron with copper wire;

[0080] (3) Turn on the power supply of the rectifier, turn on the start switch, switch to the stable voltage state, turn the knob, set the required voltage 2~3V, and turn off the start switch;

[0081] (4) Turn on the timer switch, adju...

Embodiment 2

[0086] A method for electrolytic deburring and oxide layer removal of a tantalum foil material primary emitter for a magnetron, comprising the following steps:

[0087] (1) Take nitric acid, hydrofluoric acid, phosphoric acid, glycerin and sodium lauryl sulfate respectively, and use purified water to prepare nitric acid 450mL / L, hydrofluoric acid 180mL / L, phosphoric acid 90mL / L, glycerin: 15mL / L, sodium lauryl sulfate: 0.4g / L electrolytic solution.

[0088] Then pour the prepared electrolytic deburring and oxide layer solution into the graphite container, and connect the graphite container to the positive pole of the rectifier;

[0089] (2) Wear and fix the primary emitter of the tantalum foil material used for the magnetron with copper wire;

[0090] (3) Turn on the power supply of the rectifier, turn on the start switch, switch to the stable voltage state, turn the knob, set the required voltage 2~3V, and turn off the start switch;

[0091] (4) Turn on the timer switch, a...

Embodiment 3

[0096] A method for electrolytic deburring and oxide layer removal of a tantalum foil material primary emitter for a magnetron, comprising the following steps:

[0097] (1) Take nitric acid, hydrofluoric acid, phosphoric acid, glycerol and sodium lauryl sulfate respectively, and prepare nitric acid: 400mL / L, hydrofluoric acid: 160mL / L, phosphoric acid: 80mL / L, glycerin Alcohol: 15mL / L sodium lauryl sulfate: 0.3g / L electrolytic solution.

[0098] Then pour the prepared electrolytic deburring and oxide layer solution into the graphite container, and connect the graphite container to the positive pole of the rectifier;

[0099] (2) Wear and fix the primary emitter of the tantalum foil material used for the magnetron with copper wire;

[0100] (3) Turn on the power supply of the rectifier, turn on the start switch, switch to the stable voltage state, turn the knob, set the required voltage 2~3V, and turn off the start switch;

[0101] (4) Turn on the timer switch, adjust and set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com