Bopp antirust adhesive tape, its preparation method and application

A technology of adhesive tape and antirust agent, which is applied in the direction of chemical instruments and methods, adhesives, lamination auxiliary operations, etc., can solve the problems of pollution, solvent pollution, etc., and achieve the effect of easy reduction, prevention of metal oxidation, and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 A kind of BOPP antirust adhesive tape, its preparation method and application

[0044] A BOPP antirust adhesive tape, which is composed of BOPP plastic film and antirust glue, wherein the antirust glue is composed of the following raw materials:

[0045] Water-based pressure sensitive adhesive 75%, dimethylethanolamine 5% and rust inhibitor 20%.

[0046] Wherein, (1) described water-based pressure-sensitive adhesive comprises the raw material of following parts by weight:

[0047] Methyl methacrylate 40g, methacrylic acid 25g and ethyl acrylate 25g;

[0048] Its preparation method is carried out according to the following sequence of steps:

[0049] ① Cover the methyl methacrylate, seal it and heat it to 65°C, set aside;

[0050] ② Add methacrylic acid to methyl methacrylate in batches and stir, and add the next batch after each addition of methacrylic acid is completely dissolved until it is completely dissolved to make solution a;

[0051] ③ Add ethyl...

Embodiment 2-6B

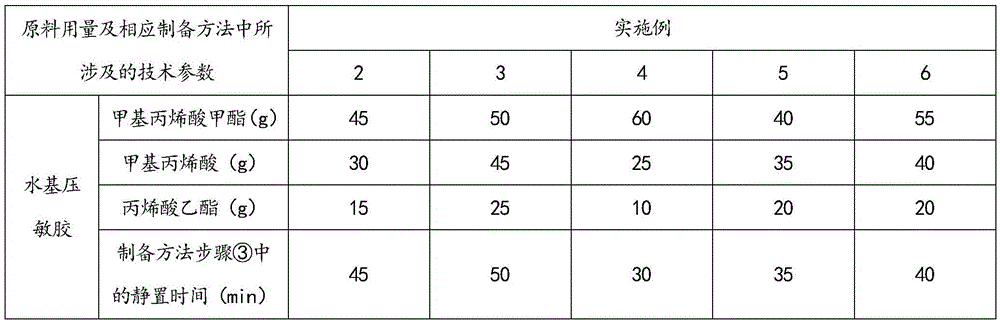

[0071] Embodiment 2-6 BOPP adhesive tape, its preparation method and application

[0072] Embodiment 2-6 is a kind of BOPP adhesive tape and preparation method thereof respectively, and its raw material and preparation method are similar to embodiment 1, and the only difference is that the used raw material dosage and the technical parameter involved in the preparation method are different, specifically As shown in the table below:

[0073]

[0074]

[0075] The BOPP anti-rust tapes prepared in Examples 2-6 can be applied to the anti-rust of various metal surfaces. The low-viscosity BOPP anti-rust tapes are used for product bonding, and the contact surface can effectively prevent metal products. Rust effect, BOPP's multi-directional high tensile strength and water resistance can protect metal from wear and tear caused by packaging and transportation, and prevent metal oxidation caused by water vapor penetration, and the anti-rust paper tape is designed with low viscosity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com