Method for preparing isobutylene from tert-butanol

A technology of tert-butanol and isobutene, which is applied in the field of isobutene preparation, can solve the problems of increasing equipment and operating costs, and achieve the effects of reducing the generation of by-product polymers and carbooctaether, high conversion rate and selectivity, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

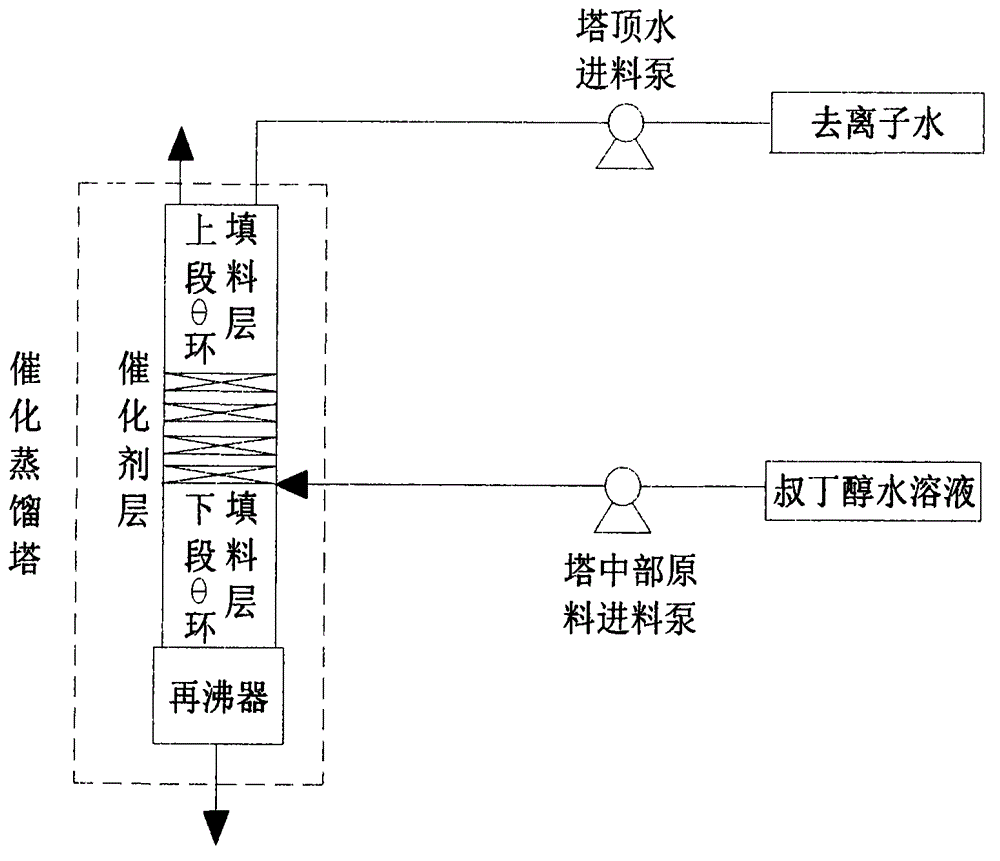

[0040] First fill the θ ring packing with 25 theoretical plates and a diameter of Ф3 below the catalyst section in the catalytic distillation tower; then fill the θ ring packing with 12 theoretical plates and a diameter of Ф3 above the catalyst section; then divide the catalyst section into 5 sections And load 15g catalyzer respectively; Back then, the tert-butanol aqueous solution that is 5% by mass content is passed into the catalytic distillation tower with flow velocity 0.15kg / h, meanwhile, deionized water enters catalytic distillation tower from tower top with flow velocity 0.12kg / h The distillation tower is heated and distilled at an operating pressure of 0.2Mpa and a tower bottom temperature of 130°C.

[0041] Among them, in Example 1 of the present invention, the temperature of the lower layer of the catalyst is 98°C, the temperature of the upper layer of the catalyst is 31°C, the conversion rate of tert-butanol is 98.50%, the selectivity is 99.93%, and the isobutene co...

Embodiment 2

[0043] First fill the θ ring packing with a theoretical plate number of 40 and a diameter of Ф3 below the catalyst section in the catalytic distillation tower; then fill the θ ring packing with a theoretical plate number of 25 and a diameter of Ф3 above the catalyst section; then divide the catalyst section into 8 sections And load 30g catalyst respectively; Immediately after that, 45% tert-butanol aqueous solution is passed into the catalytic distillation tower with a flow rate of 0.85kg / h. The tower is heated and distilled at an operating pressure of 0.1Mpa and a bottom temperature of 100°C.

[0044] Among them, in Example 1 of the present invention, the temperature of the lower layer of the catalyst is 80°C, the temperature of the upper layer of the catalyst is 73°C, the conversion rate of tert-butanol is 99.21%, the selectivity is 99.98%, and the isobutene content in the tower gas is 99.35%.

Embodiment 3

[0046] First fill the θ ring packing with 35 theoretical plates and a diameter of Ф3 below the catalyst section in the catalytic distillation tower; then fill the θ ring packing with a theoretical plate number of 20 and a diameter of Ф3 above the catalyst section; then divide the catalyst section into 7 sections And load 25g catalyzer respectively; Immediately after that, the tert-butanol aqueous solution with a mass content of 15% is passed into the catalytic distillation tower with a flow rate of 0.65kg / h. The tower is heated and distilled at an operating pressure of 0.3Mpa and a tower bottom temperature of 180°C.

[0047] Among them, in Example 1 of the present invention, the temperature of the lower layer of the catalyst is 110°C, the temperature of the upper layer of the catalyst is 36°C, the conversion rate of tert-butanol is 99.58%, the selectivity is 99.96%, and the isobutene content in the tower gas is 99.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com