A preparation method of flaky graphene and a flaky graphene device prepared using the method

A flake graphite and flake graphite technology, which is applied in the field of flake graphene devices, can solve the problems of low purity, limited graphene application, and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

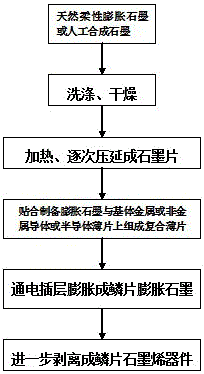

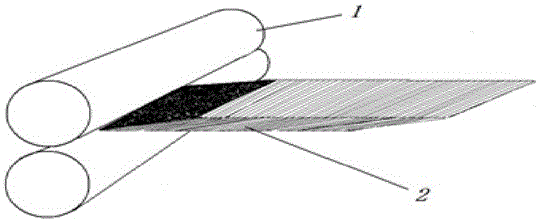

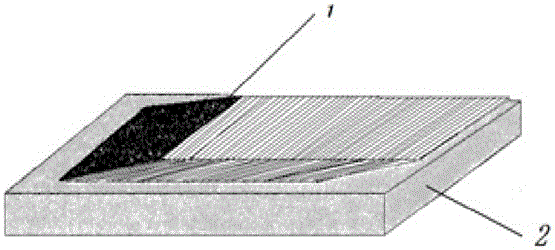

[0089] Example 1 Preparation of scaly graphene by bonded electrolytic microwave method Take a piece of flexible expanded graphite flakes, wash and dry, and use a roller press to gradually adjust the gap for repeated rolling. During the rolling process, auxiliary heating is carried out at the same time to increase the flexibility of the graphite. Roll until The thickness of the graphite sheet is 0.05mm, and the process is as follows figure 1 and figure 2 As shown, the expanded graphite flakes are obtained.

[0090] Mix 96.85% of acetylene black (conductive agent, particle size: about 10nm), 1.55% of CMC (sodium carboxymethyl cellulose), and 1.60% of SBR (styrene-butadiene rubber) to form a paste slurry. Spread the pasty slurry evenly on the aluminum foil with a thickness of 0.01 mm. Then evenly cover the expanded graphite flakes on the spread paste slurry, and the spread thickness is 0.08mm, and then vacuum-dry the covered wet expanded graphite-aluminum composite flakes at r...

Embodiment 2

[0092] Example 2 Preparation of flaky graphene by spray electrolysis microwave method

[0093] Take a piece of flexible expanded flake graphite, wash and dry it, and use a roller press to gradually adjust the gap for repeated calendering. During the calendering process, auxiliary heating is carried out at the same time to increase the flexibility of the graphite, and calender until the thickness of the graphite flake is 0.025mm. The process is as follows: figure 2 As shown, the expanded graphite flakes are obtained.

[0094] Arc spray the aluminum layer on the expanded graphite sheet obtained after calendering. The compressed air used for spraying should be clean and dry, the pressure should not be less than 0.4MPa, and the spraying distance should be 250mm. 45°, the moving speed of the spray gun should reach 50 μm in one spraying thickness, there should be 1 / 3 of the width overlap between the spraying strips, the thickness should be as uniform as possible, the spraying guns ...

Embodiment 3

[0097] Example 3 Preparation of flaky graphene by hot pressing electrolytic microwave method

[0098] Take a piece of flexible expanded flake graphite, wash and dry it, and use a roller press to gradually adjust the gap to carry out repeated calendering. During the calendering process, auxiliary heating is carried out at the same time to increase the flexibility of the graphite, and calender until the thickness of the graphite flake is 0.05mm. The process is as follows: figure 1 and figure 2 As shown, the expanded graphite flakes are obtained.

[0099] Heat and press the expanded graphite flakes obtained after calendering in contact with the aluminum flakes. The heating temperature is 650°C, and the pressure is 5 MPa to make the aluminum flakes plastically deform so that they can be bonded to the expanded graphite flakes to obtain expanded graphite-aluminum. Composite flakes.

[0100] Use the expanded graphite-aluminum composite sheet as the anode, use 10M sulfuric acid aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com