Co-refining catalyst for kerosene hydrogenation and its preparation method and application method

A catalyst and kerosene technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of difficult recovery of catalyst molybdenum, achieve good hydrocracking activity, high product oil yield, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of above-mentioned catalyst, by the following steps:

[0026] 1. According to the formula of the carrier, add the carrier into the calculated amount of weakly acidic solution containing zinc chloride or tin chloride, stir at 30-90°C for 1-4 hours and then wash, then wash the carrier at 80 drying at a temperature of ~150°C for 1 to 6 hours to obtain the carrier;

[0027] 2. According to the formula of iron salt and nickel salt, mix iron salt and nickel salt to form an aqueous solution, immerse the carrier prepared in step 1 in the aqueous solution of iron salt and nickel salt at a temperature of 30-90°C for 1-8 hours, Then filter the impregnated carrier, add a weak alkaline solution to the filtered carrier, stir for 1 to 4 hours, and then put it in a temperature of 80 to 150°C and dry for 4 to 18 hours to prepare the active ingredient the catalyst;

[0028]3. The catalyst prepared in step 2 is vulcanized under the action of a vulcanizing agent at...

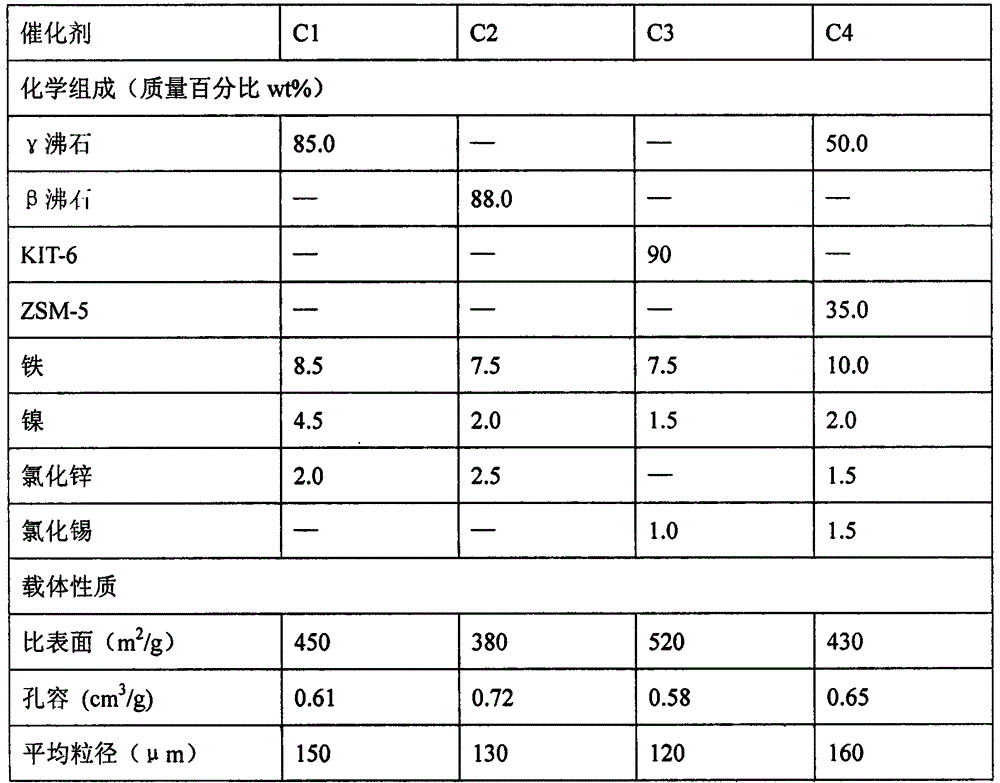

Embodiment 1

[0033] Take the calculated amount of gamma zeolite, add it to the calculated amount of acetic acid solution containing zinc chloride (pH is 6.0), stir at 60°C for 2 hours, wash it, put it into a 120°C oven and dry it for 2 hours to obtain additive-containing carrier.

[0034] Take the calculated amount of ferric chloride and nickel sulfate, mix them into an aqueous solution, immerse the carrier containing additives prepared above in the aqueous solution of ferric chloride and nickel sulfate at a temperature of 80°C for 4 hours, and add to the carrier after filtering A small amount of sodium carbonate solution (pH 10.0), stirred for 2 hours, and then dried in an oven at 150°C for 8 hours, was prepared as a catalyst containing active components.

[0035] The catalyst prepared above was sulfided under the action of carbon disulfide at a temperature of 200° C. to finally obtain the finished catalyst C1 with hydrogenation activity.

Embodiment 2

[0037] Take the calculated amount of zeolite beta, add it into the calculated amount of acetic acid solution containing zinc chloride (pH is 6.0), stir at 60°C for 3 hours, wash it, put it into a 120°C oven and dry it for 3 hours to obtain additive-containing carrier.

[0038] Take the calculated amount of ferrous chloride and nickel nitrate, mix them into an aqueous solution, immerse the carrier containing additives prepared above in the aqueous solution of ferrous chloride and nickel nitrate at a temperature of 70°C for 4 hours, and filter the carrier A small amount of sodium carbonate solution (pH 10.0) was added to the mixture, stirred for 3 hours, and then dried in an oven at 150°C for 12 hours to prepare a catalyst containing active components.

[0039] The catalyst prepared above was vulcanized under the action of dimethyl disulfide at a temperature of 250° C. to finally obtain the finished catalyst C2 with hydrogenation activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com