Multi-element composite titanium pot and manufacturing process

A composite titanium pot, multi-component technology, applied in the field of kitchen utensils and pots, can solve the problems of high manufacturing cost, inability to use induction cooker, heavy quality, etc., and achieve the effects of convenient production, energy saving and fast cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

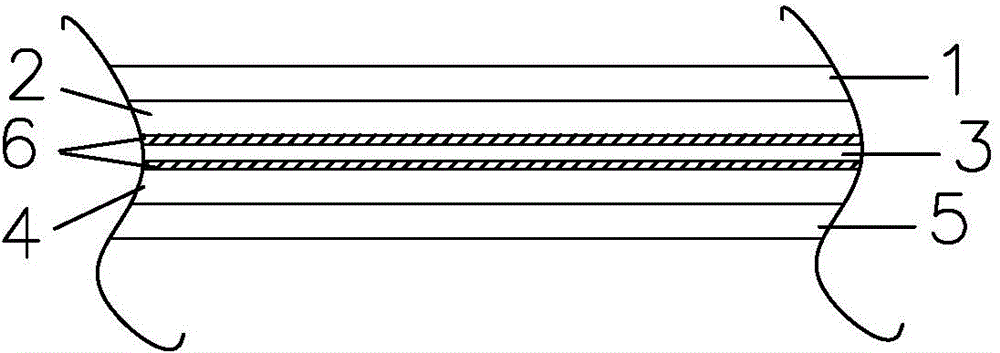

[0030] Such as figure 1 As shown, the multi-component composite titanium pot has an overall thickness of 2.2mm, including 0.5mm pure titanium layer 1, 0.5mm pure aluminum layer 2, 0.2mm copper layer 3, 0.5mm aluminum alloy layer 4 and 0.5mm non-magnetic 304 stainless steel layer 5.

[0031] Wherein, the roughness of the side of the pure titanium layer close to the pure aluminum layer is 0.05 mm. Both sides of the red copper layer are plated with nano-silver heat conducting layer 6 (which can also be nano-copper or nano-aluminum).

[0032] Its production process is as follows:

[0033] The first step, pretreatment, is to clean the surface of the pure titanium plate with a thickness of 0.5mm, and use a metal cleaning agent to remove impurities such as oil stains on the surface;

[0034] The second step is pre-treatment, so that the roughness of one side is 0.05mm, that is, sandblasting is performed on one side of the pure titanium plate treated in the first step to remove the...

Embodiment 2

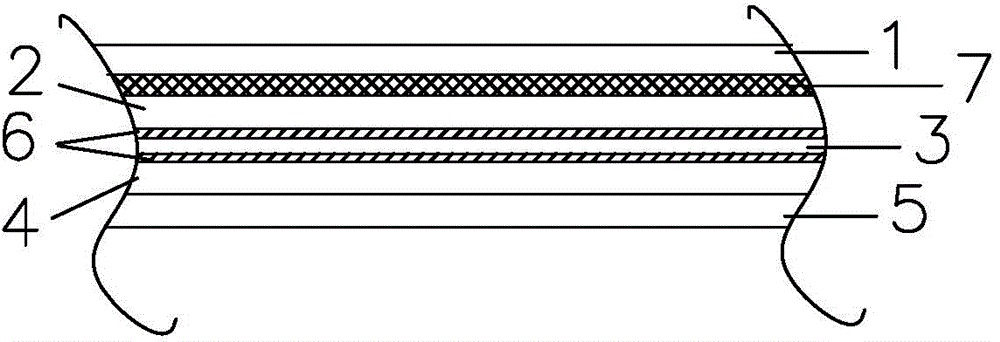

[0038] Such as figure 2 As shown, the multi-component composite titanium pot has an overall thickness of 2.2mm, including 0.5mm pure titanium layer 1, 0.5mm pure aluminum layer 2, 0.2mm copper layer 3, 0.5mm aluminum alloy layer 4 and 0.5mm non-magnetic 304 stainless steel layer 5.

[0039] Wherein, the roughness of the side of the pure titanium layer close to the pure aluminum layer is 0.05 mm, and the side of the pure titanium layer close to the pure aluminum layer is coated with a nanoscale metal adhesion layer 7 of nano-aluminum with high bonding force. Both sides of the red copper layer are plated with a nano-aluminum heat-conducting layer 6 (which can also be nano-silver or nano-copper).

[0040] Its manufacturing process is as follows:

[0041] The first step, pretreatment, is to clean the surface of the 0.5mm pure titanium plate, and use a metal cleaning agent to remove impurities such as oil stains on the surface.

[0042] The second step is pre-treatment to make ...

Embodiment 3

[0047] Can refer to figure 2 , multi-component composite titanium pot, the overall thickness is 3.1mm, including 0.6mm pure titanium layer 1, 0.6mm pure aluminum layer 2, 0.5mm copper layer 3, 0.8mm aluminum alloy layer 4 and 0.6mm magnetic 430 stainless steel layer from inside to outside 5. Suitable for induction cooker.

[0048] Among them, the roughness of one side of the pure titanium layer is 0.06 mm, and the side of the pure titanium layer close to the pure aluminum layer is coated with a nano-silver nanoscale metal adhesion layer 7 with high binding force. Both sides of the red copper layer are plated with nano-silver heat conduction layer 6 .

[0049] Its manufacturing process is as follows:

[0050] The first step, pretreatment, is to clean the surface of the 0.6mm pure titanium plate, and use a metal cleaning agent to remove impurities such as oil stains on the surface;

[0051] The second step is pre-treatment, so that the roughness is 0.06mm, and sandblasting is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com