A kind of production method of spicy soy sauce

A production method and technology of soy sauce, which are applied in the field of food processing, can solve the problems of not being able to taste a whole, and achieve the effects of preventing pollution, avoiding the use of food, and inhibiting the growth of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of production method of spicy soy sauce, comprises the following steps:

[0024] (1) Ratio of koji-making materials: 700kg of soybeans, 300kg of flour, 1000kg of feed in each koji-making pool, and 0.3% inoculum amount of koji. The color of the prepared koji is yellow-green, the koji spores are plump and loose, without blackening or flakes, and have the inherent aroma of koji without ammonia, rancidity and other bad smells.

[0025] (2) Soybean soaking: The skin of soaked soybeans is smooth and can be peeled by light pinching, and the two petals of soybeans are broken and the bean heart is full and dry.

[0026] a. The amount of water added for soaking: about 1.1 times the weight of soybeans, and the surface height of soaked soybeans is about 60cm.

[0027] b. Soaking time: about 2-4 hours in summer and autumn, and about 4-8 hours in spring and winter.

[0028] (3) Soybean steaming: Lightly pinch cooked beans into flakes without hard core, cooked but not rotten,...

Embodiment 2

[0049] A kind of production method of spicy soy sauce comprises the following steps, and other steps and parameters are with embodiment 1.

[0050] (1) Add water to soak the soybeans for 4 hours, cook the soybeans, and cool them down;

[0051] (2) Mix the flour and the small koji seeds evenly, stir the cooked beans, flour and bacterial classification evenly, the inoculation amount of the bacterial classification is 0.3%, and the mass ratio of soybean and flour is 700:300;

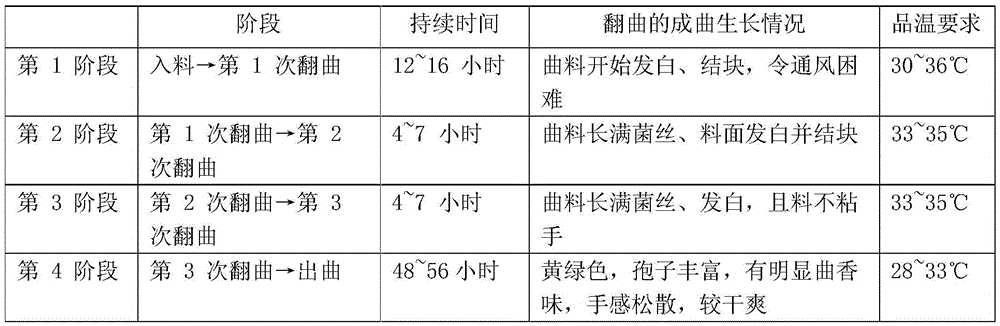

[0052] (3) Ventilated koji making, including 3 times of turning, from feeding to the first turning stage, the temperature is 30°C, and the first turn is 16 hours after feeding; keep the temperature at 33°C, the second time after 7 hours Turn over the koji; keep the temperature at 33°C, and turn over the koji for the third time after 7 hours; keep the temperature at 28°C, and make the koji after 56 hours;

[0053](4) adding salt water to ferment, the concentration of salt water is 16.5 ° Be, and the ferment...

Embodiment 3

[0060] A kind of production method of spicy soy sauce comprises the following steps, and other steps and parameters are with embodiment 1.

[0061] (1) Add water to soak the soybeans for 8 hours, cook the soybeans, and cool them down;

[0062] (2) Mix the flour and the small koji seeds evenly, stir the cooked beans, flour and bacterial classification evenly, the inoculation amount of the bacterial classification is 0.3%, and the mass ratio of soybean and flour is 1000:300;

[0063] (3) Ventilated koji making, including 3 times of turning, from feeding to the first turning stage, the temperature is 36°C, the first turning is 13 hours after feeding; keep the temperature at 35°C, the second time after 5 hours Turn over the koji; keep the temperature at 35°C, and turn over the koji for the third time after 5 hours; keep the temperature at 33°C, and make the koji after 48 hours;

[0064] (4) adding salt water to ferment, the concentration of salt water is 18.5 ° Be, and the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com