Leisure taro puffed crisp chips and production process thereof

A production process and a technology for puffed chips, which are applied to the production process of leisure taro puffed chips and the field of products to achieve the effects of crisp taste, improved crispness, good color and nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

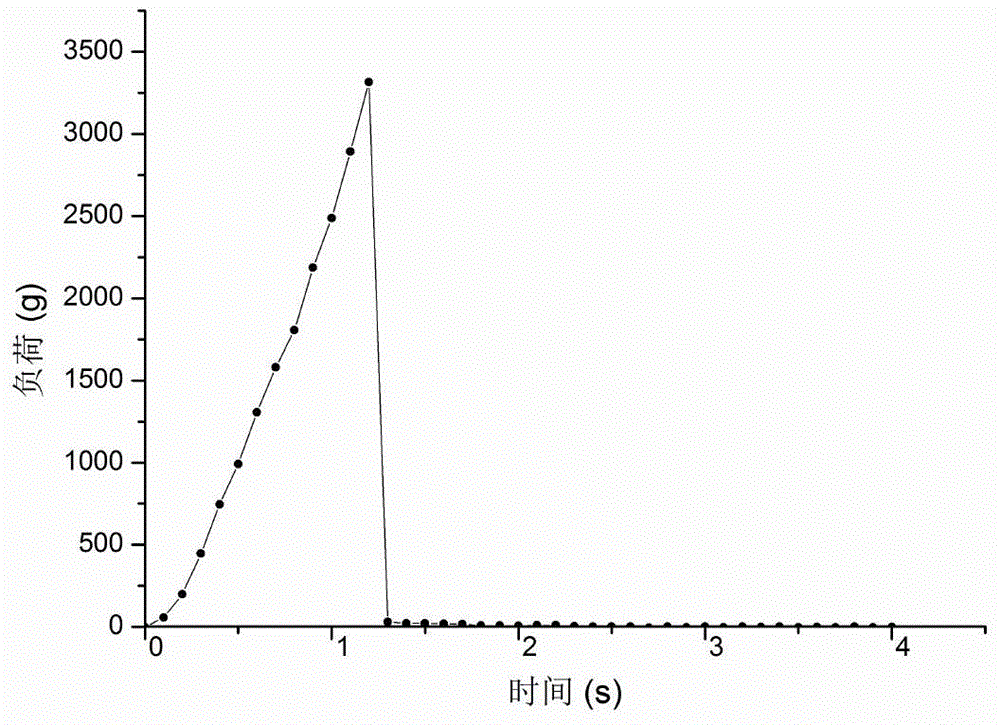

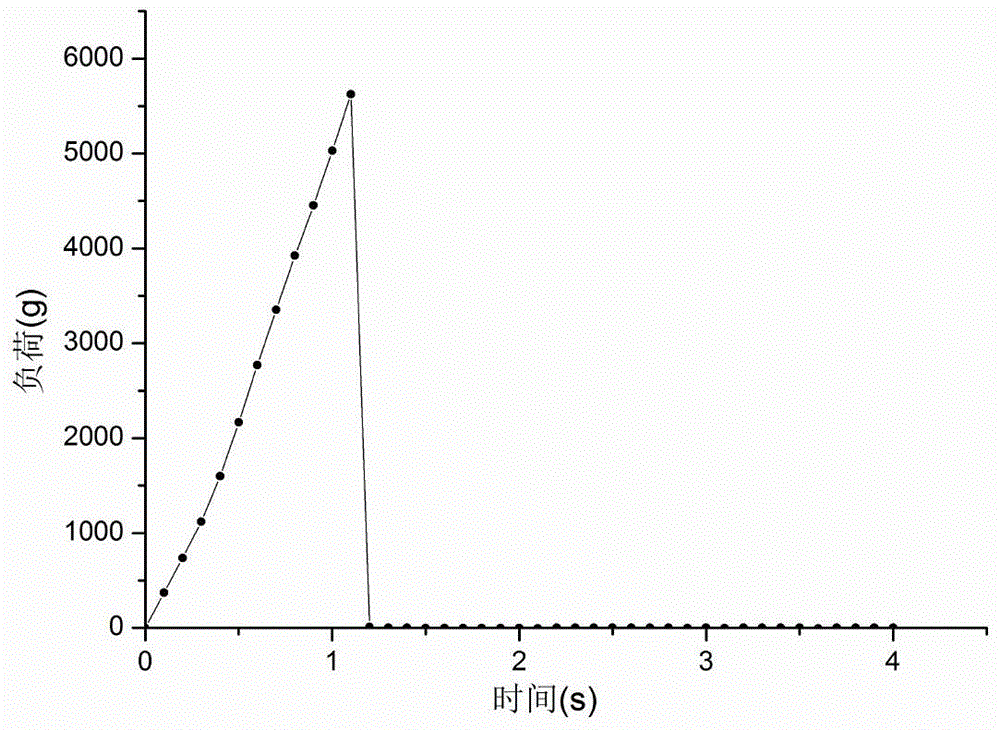

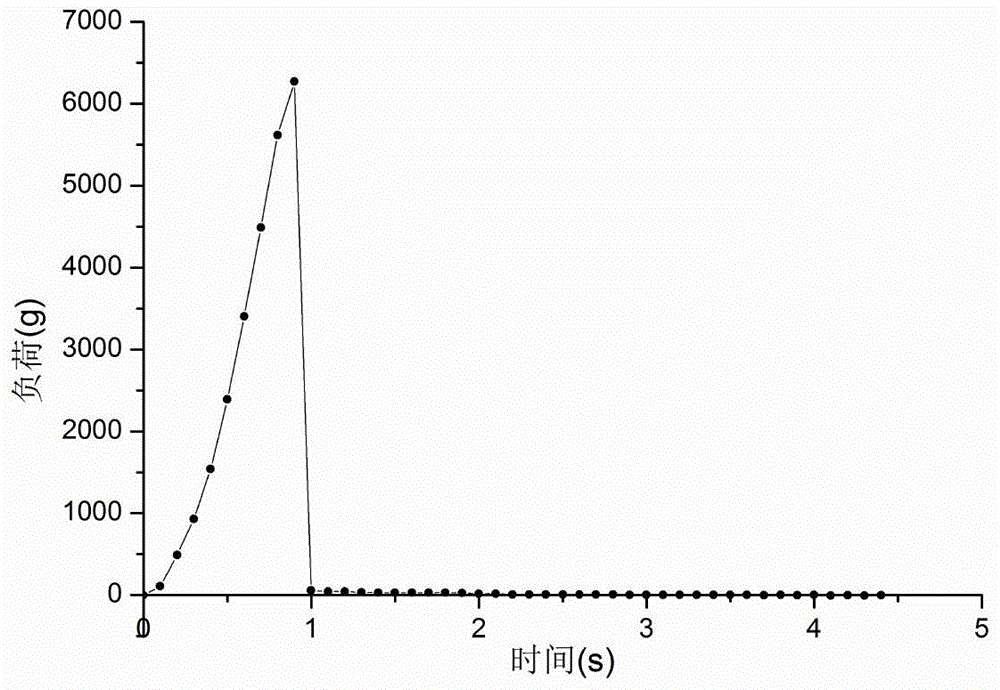

Image

Examples

Embodiment 1

[0031] Select three varieties of Jiangsu Xinghua Longxiang taro with an individual weight of more than 0.5kg, Fujian Fuding betel nut taro and Guangxi Lipu taro (all purchased from the market). Fresh and complete taro raw materials are washed with surface soil and peeled. Cut taro into slices with a thickness of 4 mm, blanching in water at 95°C to 100°C for 3 minutes, soaking in 1.5% NaCl, 0.2% citric acid color protection solution for 30 minutes, and then soaking in 2% maltodextrin for 40 minutes. Place the soaked taro slices in an electric blast drying oven at 60°C until the moisture content of the taro slices is 45-55% and then evenly wet them, then carry out two-stage vacuum microwave drying in a vacuum microwave drying equipment until the moisture content is 3.5- 4.5%. The vacuum degree is 0.088MPa, the microwave power of the first stage is 1600W, the microwave time is 60s, and the interval is 120s. Pack the taro slices in nitrogen-filled aluminum-plastic bags and store ...

Embodiment 2

[0045] Select Fenghua taro, fragrant sand taro with an individual weight of more than 0.5kg, and taro with a diameter of less than 5 cm (Longxiang taro, which refers to immature Longxiang taro, which can also be eaten, but its nutritional content is different from that of mature Longxiang taro. Many) three varieties (both purchased from the market) were measured according to the national standard for water content and starch content, and Fenghua taro was selected as raw material for the production of taro puffed chips, with a water content of 82.9% and a starch content of 16.4%. Fresh and complete Fenghua taro, wash the soil on the surface, peel off the skin, cut the peeled taro into slices with a thickness of 4 mm, and blanch it in water at 95°C to 100°C for 3 minutes, in a color-protecting solution of 1.5% NaCl and 0.2% citric acid Soak for 30 minutes, then soak in 2% maltodextrin for 40 minutes. Place the soaked taro slices in an electric blast drying oven at 60°C until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com