Polyamide-imide resin composition for lubricating coating material

A technology of polyamide-imide resin and polyamide-imide, applied in lubricating compositions, coatings, base materials, etc., can solve problems such as deterioration of storage stability of lubricating coatings, achieve long-term dissolution, excellent Excellent effect of heat resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

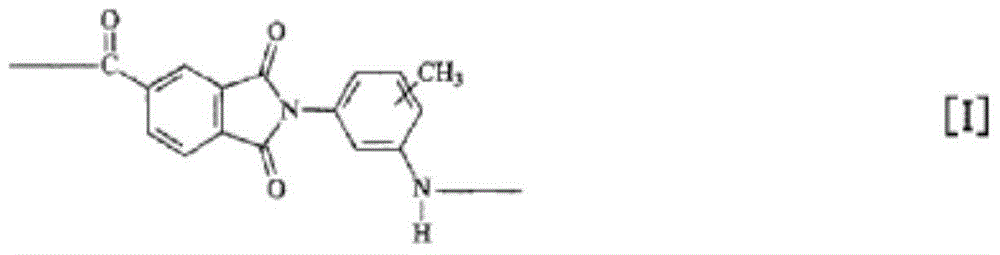

Image

Examples

Embodiment 1

[0112] In a 4-neck flask equipped with a nitrogen inlet pipe and a cooling device, add 192.1 g (1 mole) of trimellitic anhydride as an acid component, 165.5 g (0.95 mole) of toluene-2 as an isocyanate component, and 165.5 g (0.95 mole) as The polymerization solvent is a solvent in which the mass ratio of γ-butyrolactone and 1,3-dimethyl-2-imidazolidinone is adjusted to 99 / 1 (hereinafter referred to as "adjusting solvent"), and the solid content The concentration was 25% by mass (the solid content concentration was calculated from the solid content (resin content) and the solvent amount in the state where the raw materials were reacted to undergo decarboxylation). Then, under nitrogen atmosphere, it was made to react at 130 degreeC for 5 hours, stirring, and the polyamide-imide resin was polymerized. Subsequently, the polyamide-imide resin solution was cooled, and diluted with the above-mentioned adjustment solution so that the solid content concentration of the polyamide-imi...

Embodiment 2~8

[0114] Except that all the acid components are set as 1 mole, all the isocyanate components are set as 0.95 moles, and the acid component, the isocyanate component and the adjustment solvent are changed to the composition of Table 1, all the other make the solid content concentration . Conditions, such as atmosphere and reaction time, were the same, and the polyamide-imide resin composition of Examples 2-8 were produced respectively. Table 1 shows the details of the polyamide-imide resin compositions of Examples 2 to 8, and Table 2 shows the evaluation results.

Embodiment 9

[0116] In a 4-neck flask equipped with a nitrogen inlet pipe and a cooling device, add 192.1 g (1 mole) of trimellitic anhydride as an acid component, 165.5 g (0.95 mole) of toluene-2,4-diisocyanate as an isocyanate component, and 821 g of N-methyl-2-pyrrolidone as a polymerization solvent was adjusted to a solid content concentration of 25% by weight, and reacted at 130° C. for 5 hours while stirring under a nitrogen atmosphere to polymerize a polyamide-imide resin. In addition, the solid content concentration was calculated from the solid content (resin content) and the solvent amount in the state which reacted and decarboxylated the raw material. Then, the polyamideimide resin solution was cooled, diluted with N-methyl-2-pyrrolidone so that the solid content concentration of the polyamideimide resin became 20% by weight, and the obtained polyamideimide resin was dilute with acetone. The polyamideimide resin in the composition is precipitated and precipitated, and after remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com