Film uncovering agent, film uncovering agent preparation method and LED chip film pouring loss reduction method

A technology of LED chip and film-removing agent, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of grain loss and high toxicity of film-removing agent, etc., to reduce the loss of inverted film, facilitate the film-removing operation, and soften the effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

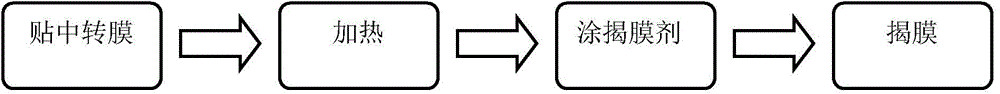

Method used

Image

Examples

Embodiment 1

[0038] A film remover, its composition and mass parts are: 10 parts of acetone, 10 parts of isopropanol, 1 part of nitric acid (68% by mass).

[0039] In order to obtain the above-mentioned substances, a preparation method of a film-removing agent, the steps are:

[0040] (a) Weigh 10 parts of isopropanol and 1 part of nitric acid (68% in mass fraction) according to the mass ratio, add them into a blending kettle with a stirring device, and stir at 55°C for 25 minutes;

[0041] (b) 10 parts of acetone are added dropwise at a speed of 2 parts / minute in the blending kettle in step (a);

[0042] (c) Stand still for 15 minutes after the dropwise addition, and then cool to room temperature to obtain the above-mentioned film release agent.

[0043] The film release agent in this embodiment has safe components, good dispersion of each substance in the mixture, can quickly soften the blue film and can quickly volatilize, and will not penetrate the blue film to contaminate the chip. ...

Embodiment 2

[0052] A film remover, its composition and mass parts are: 15 parts of acetone, 30 parts of isopropanol, 3 parts of nitric acid (68% by mass).

[0053] In order to obtain the above-mentioned substances, a preparation method of a film-removing agent, the steps are:

[0054] (a) Weigh 30 parts of isopropanol and 3 parts of nitric acid into a blending kettle with a stirring device according to the mass ratio, and stir at 60°C for 20 minutes;

[0055] (b) 15 parts of acetone are added dropwise at a speed of 2 parts / minute in the blending kettle in step (a);

[0056] (c) Stand still for 15 minutes after the dropwise addition, and then cool to room temperature to obtain the above-mentioned film release agent.

[0057] The film release agent in this embodiment has safe components, good dispersion of each substance in the mixture, can quickly soften the blue film and can quickly volatilize, and will not penetrate the blue film to contaminate the chip.

[0058] A method for reducing ...

Embodiment 3

[0066] A film remover, the composition and mass parts are: 12 parts of acetone, 20 parts of isopropanol, and 2 parts of nitric acid (68% by mass).

[0067] In order to obtain the above-mentioned substances, a preparation method of a film-removing agent, the steps are:

[0068] (a) Weigh 20 parts of isopropanol and 2 parts of nitric acid into a blending kettle with a stirring device according to the mass ratio, and stir at 40°C for 30 minutes;

[0069] (b) 12 parts of acetone are added dropwise at a speed of 2 parts / minute in the blending kettle in step (a);

[0070] (c) Stand still for 15 minutes after the dropwise addition, and then cool to room temperature to obtain the above-mentioned film release agent.

[0071] The film release agent in this embodiment has safe components, good dispersion of each substance in the mixture, can quickly soften the blue film and can quickly volatilize, and will not penetrate the blue film to contaminate the chip.

[0072] A method for reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com