Energy-saving sectional type water stop split screw rod device

A split-screw, segmented technology, which is applied in the field of energy-saving segmented water-stop split-screw devices, can solve the problems of non-reusable, labor-intensive, difficult, etc., to ensure the water-stop effect and save the gas cutting process , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

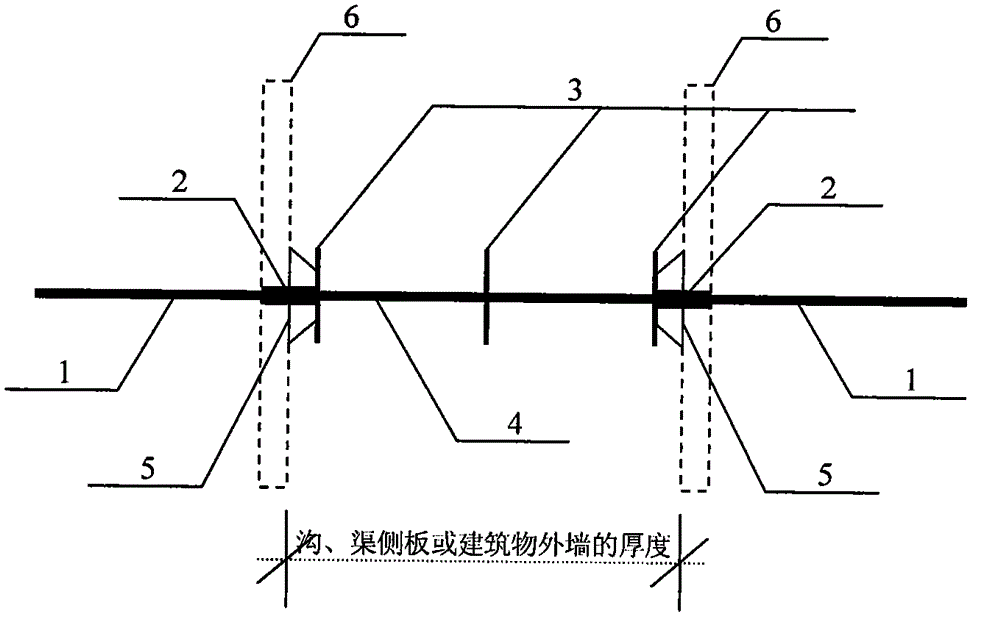

[0009] Specific implementation method: The energy-saving segmented water-stop double-pull screw device consists of two Φ12 full-threaded short screws (1), two M12 long nuts (2), and a Φ12 middle belt 3 with threaded buckles at both ends. The long screw rod (3,4) of sheet water stop sheet, two plastic conical caps (5) form.

[0010] During construction, firstly select a Φ12 long screw according to the thickness of the side plate of the ditch, canal or building exterior wall, put on the two ends of the screw with a length of not less than 40mm, and weld the water-stop sheet in the middle and the end of the screw respectively. At the same time, choose two short screws of Φ12, L≥150mm, and set them with full wires.

[0011] Connect the Φ12 long screw with threaded buckles at both ends and 3 waterstops in the middle with the Φ12 full-threaded short screw with M12 long nuts, put on the plastic conical cap, close the plywood template, and put on the 1g mountain-shaped clip Finally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com