Method and system for calibrating camera parameters of one-dimensional area array camera set

A camera parameter, camera technology, applied in image data processing, instrumentation, calculation, etc., can solve the problem of not providing a more accurate camera parameter calibration method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

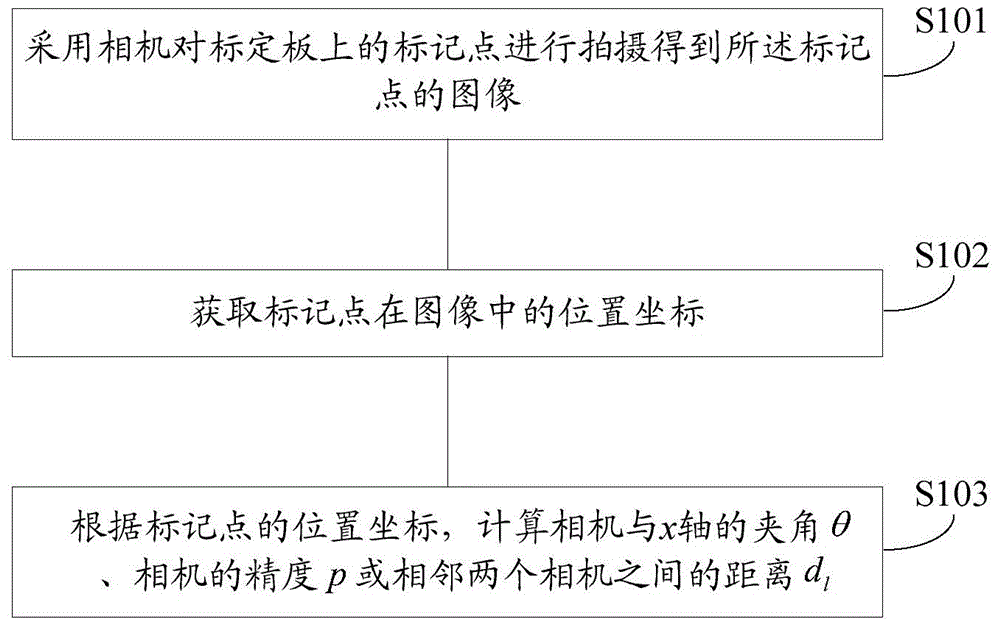

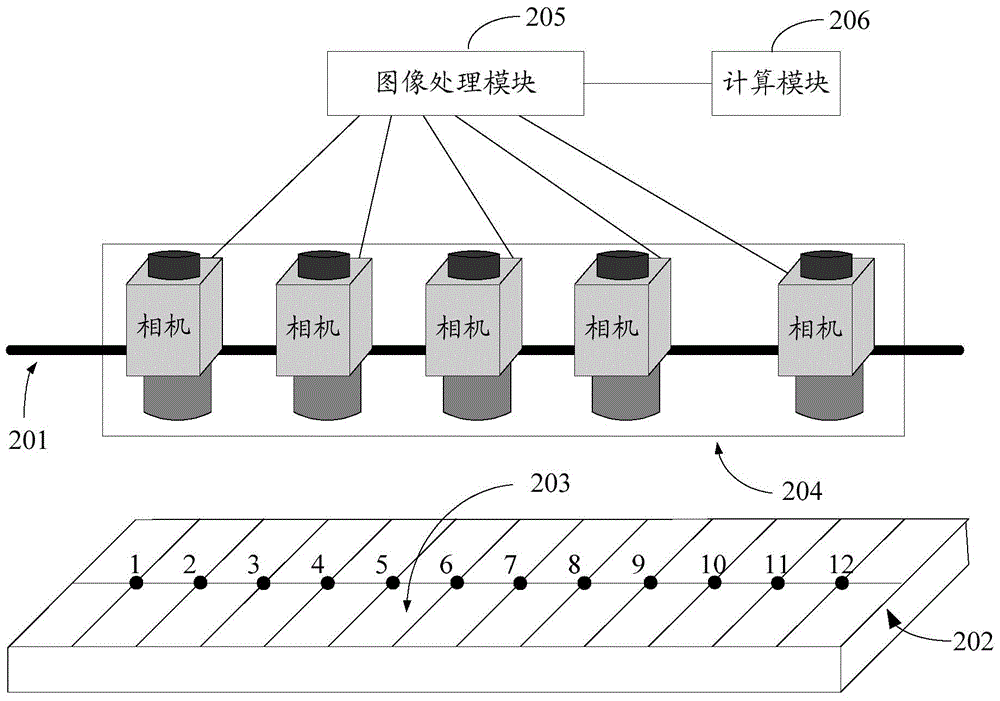

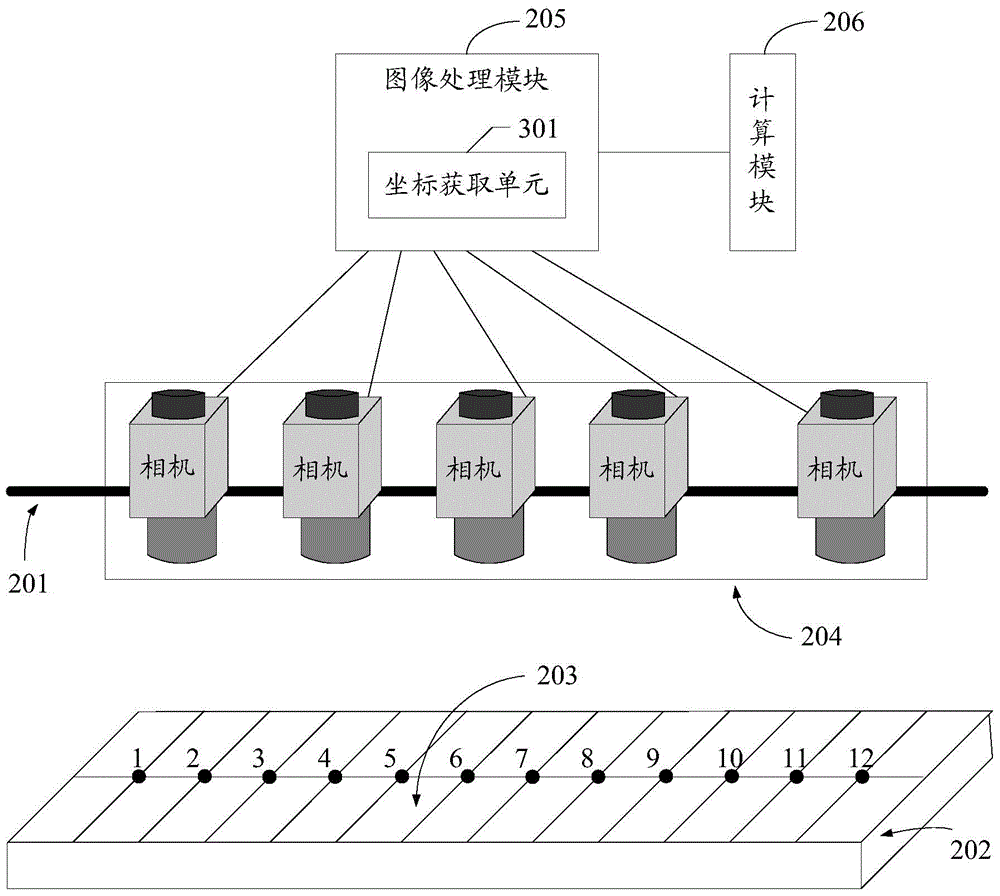

[0025] An embodiment of the present invention provides a method for calibrating camera parameters of a one-dimensional area array camera group, including: using a camera to photograph the marking points on the calibration plate to obtain images of the marking points, and the one-dimensional area array camera group is carried on x motion platform; acquire the position coordinates of the marked point in the image; calculate the angle between the camera and the x-axis, the accuracy of the camera and the distance between two adjacent cameras according to the position coordinates of the marked point. Embodiments of the present invention also provide a corresponding system for calibrating camera parameters of a one-dimensional area array camera group. Each will be described in detail below.

[0026] The basic flow of the method for calibrating the camera parameters of the one-dimensional area array camera group in the embodiment of the present invention can be referred to figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com