Dynamic balance suppression method for spatial vibration of high-speed rotor bearing system

A system space, high-speed rotor technology, applied in mechanical oscillation control, non-electric variable control, control/regulation systems, etc., can solve the problems of space vibration suppression without considering rotor displacement and bearing vibration at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] This embodiment provides the specific implementation process of the present invention in engineering practice.

[0042] 1. Acquisition of rotor displacement and bearing vibration data

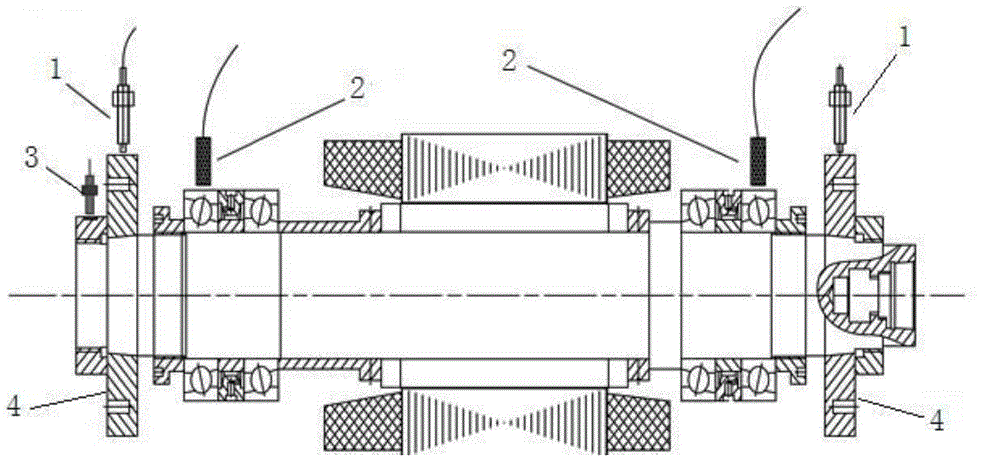

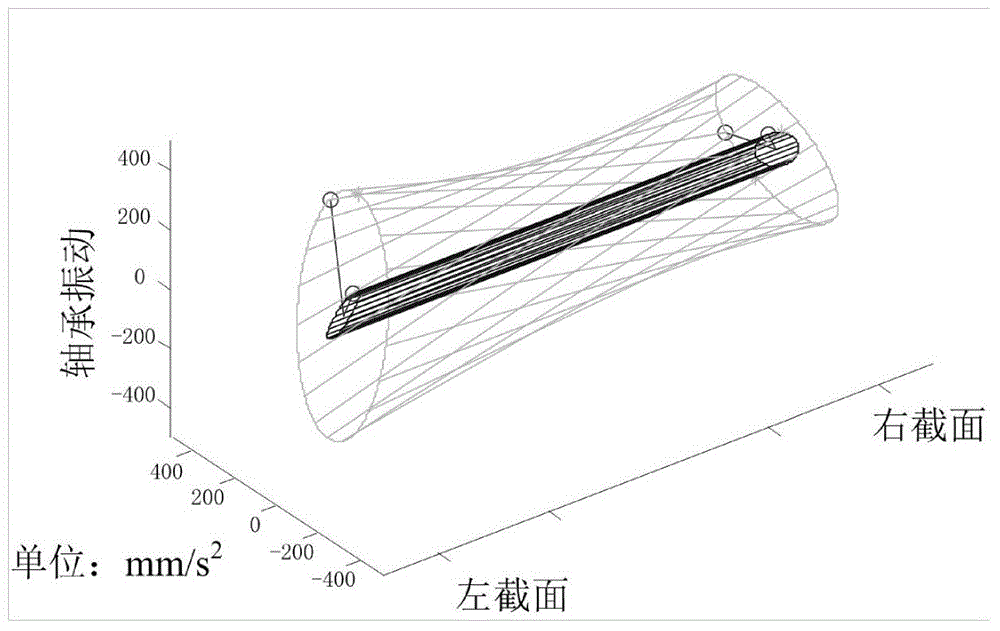

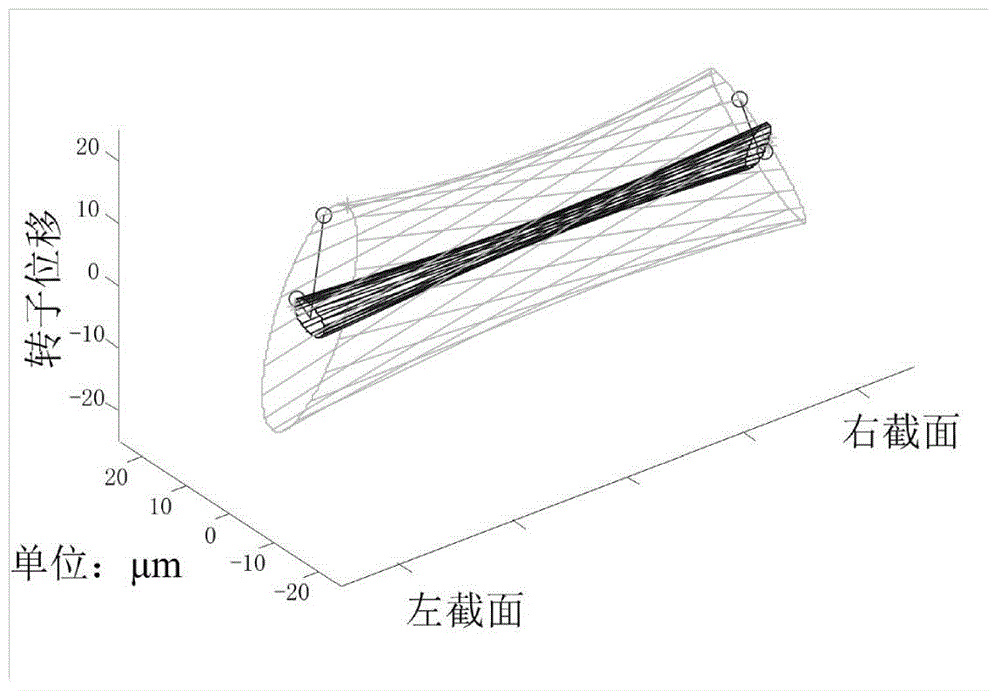

[0043] like figure 1 Shown is a schematic diagram of the model of the high-speed rotor bearing system of the present invention (only the vertical direction sensor is drawn in the figure), the structure of the high-speed rotor bearing system is the prior art, and its structure will not be described in detail here; Figure 4 It is a flow chart of the steps of the method of the present invention. The present invention collects the horizontal and vertical direction displacement signals δ of the surface of the counterweight plate through the displacement sensor 1 LH ,δ LV ,δ RH ,δ RV , through the vibration sensor 2 to collect the vibration signal υ of the bearing outer ring LH ,υ LV ,υ RH ,υ RV , collecting the phase signal through the phase detection sensor 3;

[0044] where: δ L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com