Online CT (computed tomography) nondestructive testing device

A non-destructive testing and testing platform technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low labor efficiency, affecting the service life of ray tubes, and prone to errors, etc., to achieve high work efficiency, high degree of automation, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

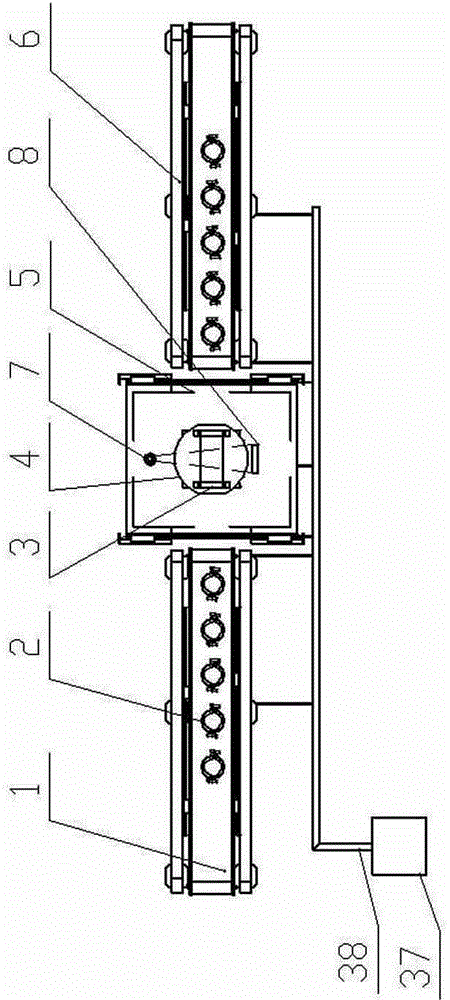

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] An online CT nondestructive testing device, such as Figure 1 to Figure 9 As shown, the detection platform 4 is installed in the protective lead room 5, and the X-ray tube 7 and the flat panel detector 8 are respectively fixed on the left and right side walls of the lead room frame 14 in the protective lead room 5. An incoming conveying line 1 and an outgoing conveying line 6 are installed on the side, and the platform conveying line 3 is installed on the detection platform 4 . in:

[0024] The feeding conveying line 1 and the outgoing conveying line 6 are composed of a conveying wire frame body 21, a conveying line anchor plate 22, a telescopic reduction motor 23, a shaft coupling 24, a screw nut seat 25, a screw nut 26, a leading screw left support 27, Conveying line electric roller 28, ball screw 29, screw right support 30, conveying line slide rail 31, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com