Non-contact gravel aggregate grain size and grain shape detector and detection method

A detector and technology for sand and gravel, applied in the non-contact sand and gravel aggregate particle size and shape detector and detection field, can solve the problems of large evaluation workload and low accuracy, and achieve strong practicability, reasonable operation, and analysis. Standard accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

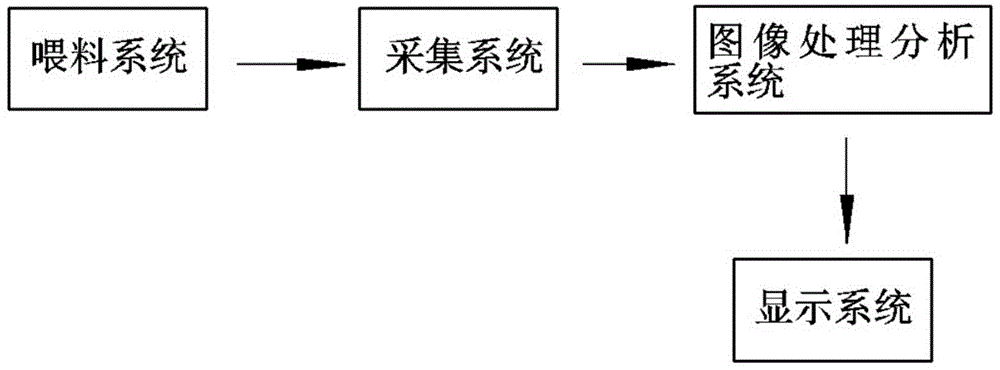

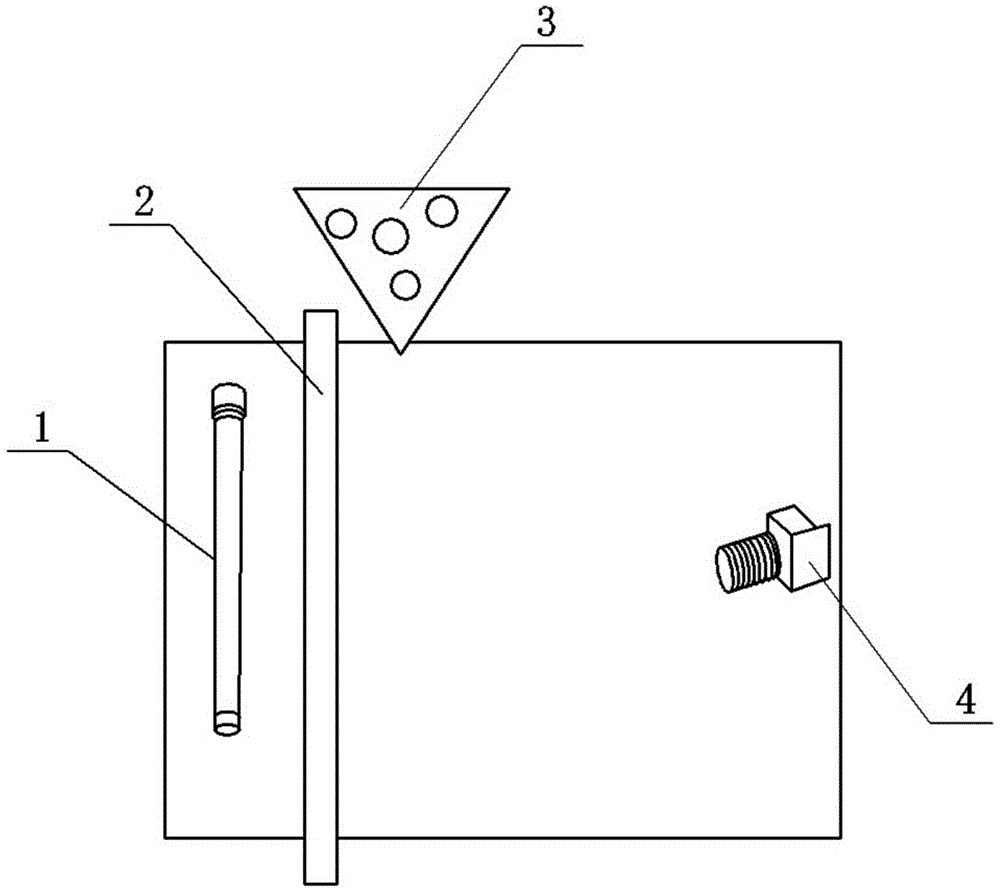

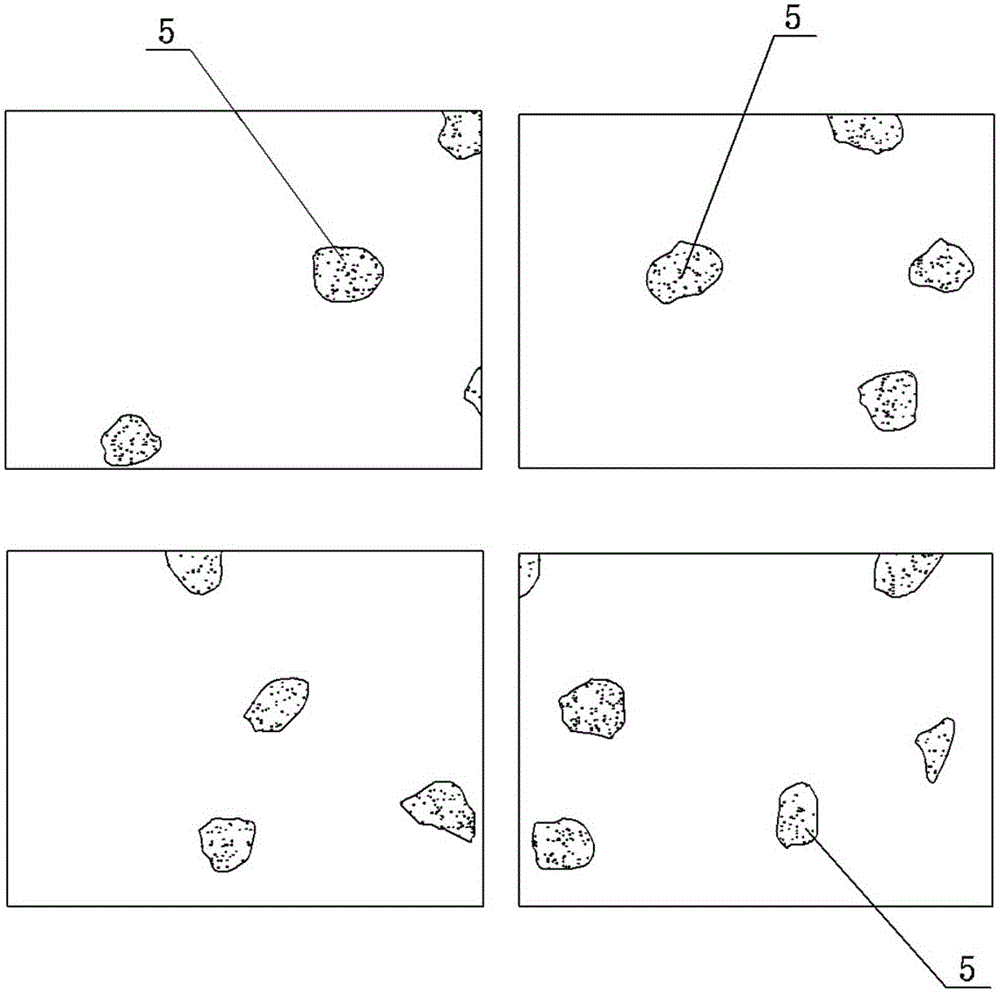

[0020] Embodiment 1: A kind of non-contact sandstone aggregate particle size particle shape detector, see figure 1 , including a feeding system, an image acquisition system, an image processing analysis system, and a display system. The feeding system completes the automatic feeding, dispersion, and discharging of stone materials. Through software control, it can automatically adjust the position and height of the sampling funnel, and control The sample flow rate enables the sample to achieve uniform dispersion and injection. like figure 2 As shown, the image acquisition system includes a light source 1, a background plate 2, and an acquisition device 4. The image acquisition system is located in a completely enclosed space with uniform illumination. The background plate 2 requires a large color difference from the sample material and strong light transmission. The light source 1 is arranged opposite to the collection device 4, an image detection area is formed between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com