Method for determining granularity area of asphalt mixture and for evaluating influence factors

An asphalt mixture and area determination technology, which is applied in the direction of using stable tension/pressure to test the strength of materials, can solve the problems of inability, difficulty in popularization, and cumbersome and complicated experimental process and data processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

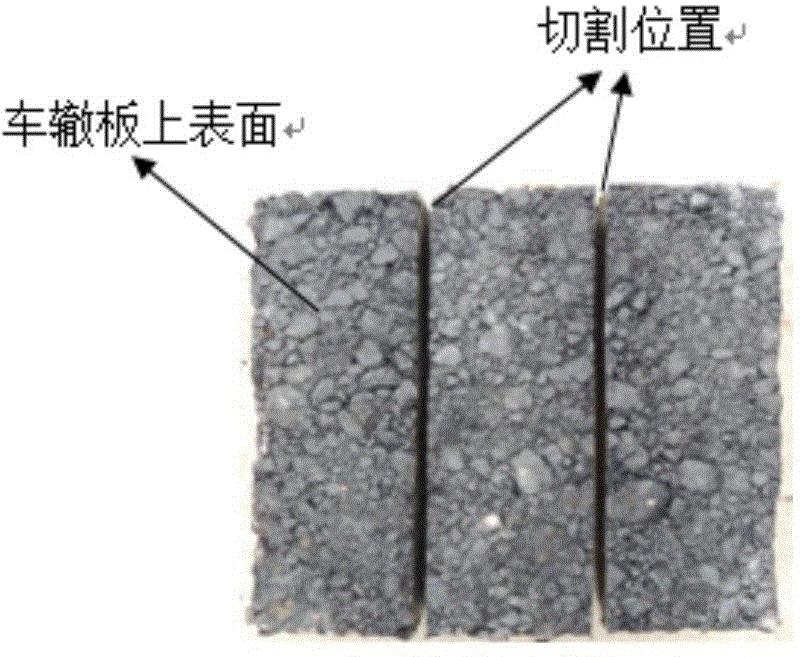

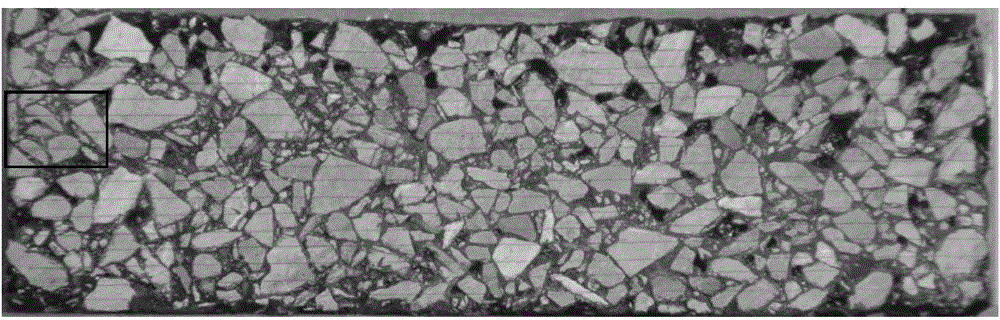

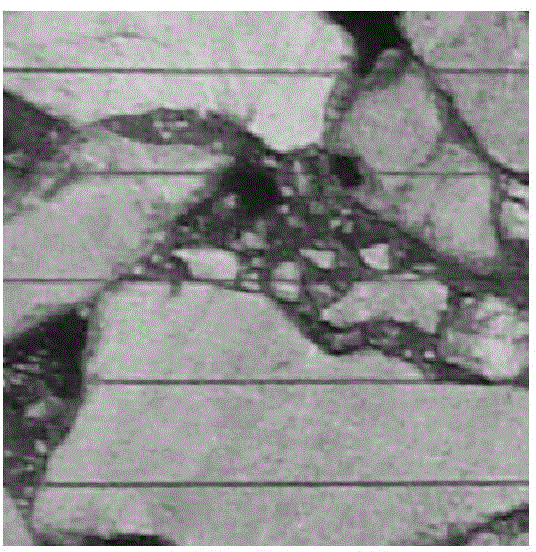

[0035] Taking the asphalt mixture specimens of AC20 and SMA20 as an example, the method of determining the granularity area and influencing factors of the asphalt mixture is as follows:

[0036] (1) Two kinds of asphalt mixtures, AC20 and SMA20, were prepared respectively according to the "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004). The aggregate was limestone gravel aggregate produced in Xianyang, Shaanxi, and the mineral powder was limestone powder. Asphalt adopts SK70# base asphalt. The technical properties of coarse aggregate, fine aggregate, filler and SK70# matrix asphalt are shown in Tables 1-4; the gradation design of the two mixtures used is shown in Table 5; the optimal asphalt ratio of the two mixtures is: The optimum asphalt-stone ratio of AC20 mixture is 4.0%, and the optimum asphalt-stone ratio of SMA20 mixture is 4.5%.

[0037] Table 1 Technical properties of coarse aggregate

[0038]

[0039] Table 2 Technical pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com