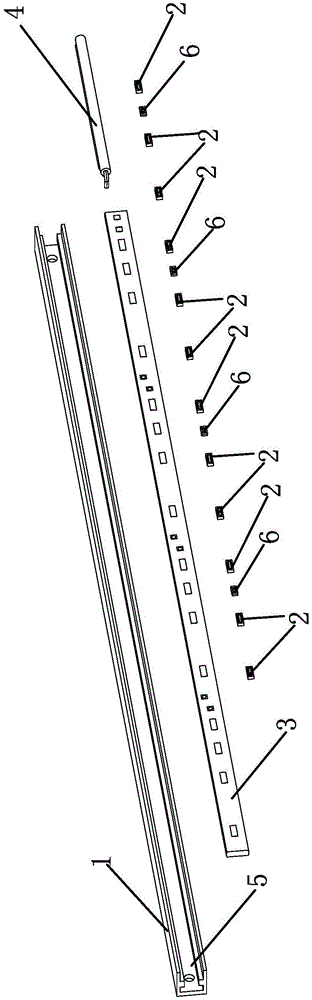

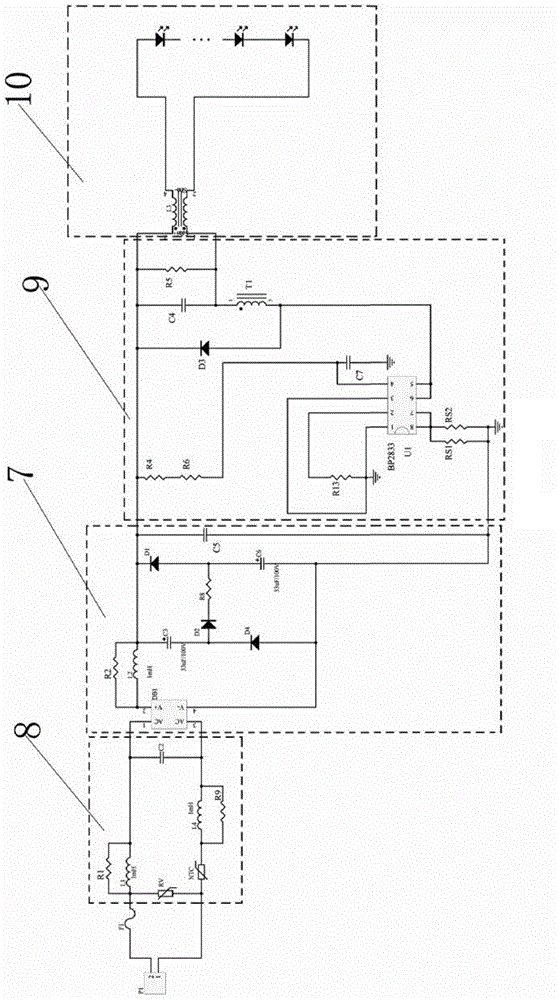

Bar-type lamp

A strip light, integrated technology, used in lighting and heating equipment, semiconductor devices of light-emitting elements, point light sources, etc., can solve problems such as insufficient thermal conductivity, difficulty in meeting heat dissipation requirements, etc., to ensure service life and save manufacturing materials. , the effect of good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

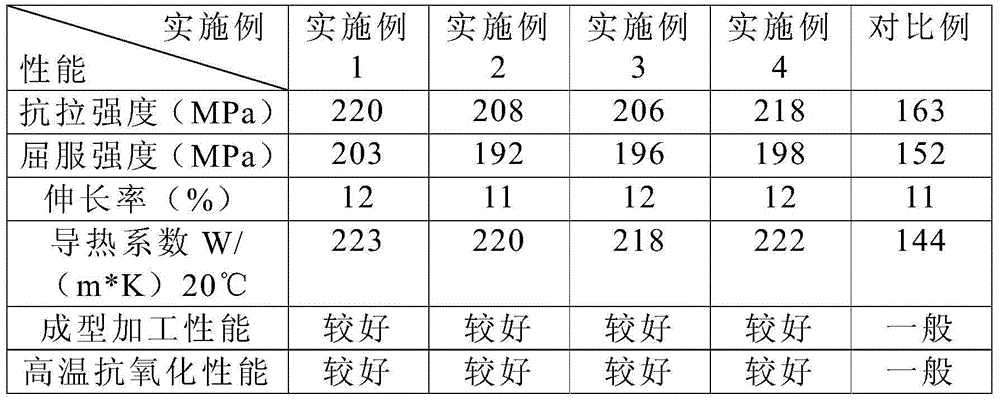

Embodiment 1

[0025] Embodiment 1: The LED substrate has a copper plate with a thickness of 0.6 mm and an aluminum alloy plate with a thickness of 1.2 mm. The copper plate and the aluminum alloy plate are bonded together by high pressure forming. The aluminum alloy plate The weight percent composition is: Si: 0.7%, Fe: 0.25%, Mg: 1.2%, Cu: 0.15%, Zn: 0.08%, Mn: 0.10%, Ag: 0.50%, La: 0.015%, Nd: 0.015% , Tb: 0.012%, the balance is Al.

Embodiment 2

[0026] Embodiment 2: The LED substrate has a copper plate with a thickness of 0.2 mm and an aluminum alloy plate with a thickness of 1.0 mm. The copper plate and the aluminum alloy plate are bonded together by high pressure forming. The aluminum alloy plate The weight percent composition is: Si: 0.30%, Fe: 0.30%, Mg: 0.52%, Cu: 0.20%, Zn: 0.05%, Mn: 0.15%, Ag: 0.30%, La: 0.02%, Nd: 0.01% , Tb: 0.015%, the balance is Al.

Embodiment 3

[0027] Embodiment 3: The LED substrate has a copper plate with a thickness of 0.8 mm and an aluminum alloy plate with a thickness of 1.4 mm. The copper plate and the aluminum alloy plate are bonded together by high pressure forming. The aluminum alloy plate The weight percent composition is: Si: 1.00%, Fe: 0.20%, Mg: 1.7%, Cu: 0.10%, Zn: 0.15%, Mn: 0.05%, Ag: 0.60%, La: 0.01%, Nd: 0.02% , Tb: 0.01%, the balance is Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com