Insulation superimposed plate and construction method

A technology of laminated board and extruded plastic board, which is applied in the direction of thermal insulation, building components, construction, etc., can solve the problems of destroying the thermal insulation performance of extruded board, poor thermal insulation effect, reducing energy saving indicators, etc., to achieve good fire safety, improve thermal insulation effect, Guarantee the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

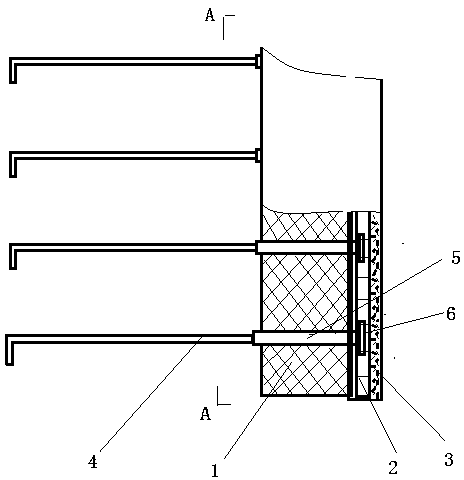

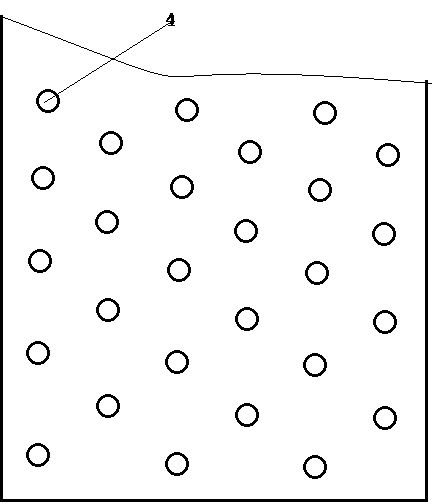

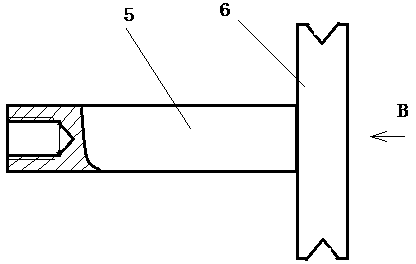

[0018] A thermal insulation laminated board integrated with the main structure concrete, which includes an extruded board 1, a steel wire mesh 2, a lightweight composite concrete layer 3 and an interface agent layer. The surface of the extruded board 1 is sprayed with an interface agent protective layer. The board 1 is covered with steel wire mesh 2 on one side, and the lightweight composite concrete layer 3 wraps the steel wire mesh 2 and is connected to the extruded board 1. The structure of the above-mentioned components and the interconnection relationship between them are the same as the prior art. To repeat, the present invention is characterized in that there are pre-embedded nylon parts and support rods 4, the pre-embedded nylon parts are distributed on the steel wire mesh 2 in a plum blossom shape, and the pre-embedded nylon parts are provided with connecting rods 5 and connecting plates 6, connecting rods 5 and The connecting disk 6 is made by one-time injection moldin...

Embodiment 2

[0021] A thermal insulation laminated board integrated with the main structure concrete, comprising an extruded board 1, a steel wire mesh 2, a lightweight composite concrete layer 3 and an interface agent layer. The extruded board 1 is a square or rectangular thin plate, and the extruded board 1 is There is an L-shaped notch on one side of the reverse side. The main purpose of setting the L-shaped notch is to adapt to the same size of the frame beam lug. Before the main frame beam structure is supported, the laminated board is installed and the outer side is installed for heat preservation simultaneously. The poured structure The concrete and the thermal insulation laminated board form a whole to achieve the effect of integration of thermal insulation and structure. It has the following characteristics: 1. The upper edge of the laminated board cuts 50% of the board thickness (45o angle) to form an L-shaped gap, which can replace the special-shaped template required for on-site ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com