Piled raft foundation anti-floating structure and construction method

A technology of pile raft foundation and anti-floating anchor rod, which is applied in the direction of foundation structure engineering, protection device, construction, etc., can solve the problems of increased groundwater buoyancy, waste of building materials, and large use of anti-lift anchor rods, so as to save construction costs. , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

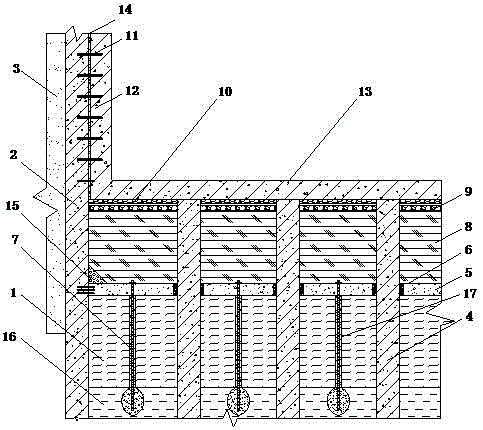

[0031] In this embodiment, the construction technology of support piles and bored cast-in-place piles, the construction of leading holes for connecting steel bars, the construction technology of anti-floating anchor rods, the construction technology of reinforced concrete water barriers and the pouring construction technology of basement bottom slabs will not be included in this embodiment. Summarizing, emphatically explain the embodiment of the present invention related to the structure.

[0032] figure 1 It is a schematic diagram of the anti-floating structure of pile cutting foundation of the present invention. refer to figure 1 As shown, the pile foundation anti-floating structure of the present invention is mainly composed of water-stop curtain 3, support pile 2, reinforced concrete water barrier 5, bored pile 4, gravel cushion 9 and anti-floating anchor rod 7.

[0033] Set up a row of supporting piles 2 around the foundation pit. The supporting piles 2 are deep mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com