Preparation method of fluorine-doped tin dioxide transparent conductive film

A technology of transparent conductive film and tin dioxide, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of adverse effects on film performance, achieve good transmittance, improve performance, and research well foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation method of fluorine-doped tin dioxide transparent conductive film

[0034] (1) Preparation method

[0035] 1) According to the solution concentration of 0.4mol / L, take 4.513g of stannous chloride dihydrate, dissolve it in 100ml of absolute ethanol, continue to stir vigorously at 70°C, add a small amount of deionized water dropwise after clarification, and stir into a sticky paste , cooled to room temperature, then put in 100ml of absolute ethanol, stirred at 50°C for 30min to form a sol, added dropwise a small amount of acetic acid to adjust the pH value to 2-3, and obtained A solution. Weigh 0.317g of ammonium fluoride, dissolve it in a small amount of deionized water, then add it to solution A, stir at 70°C for about 2 hours, leave 50ml of the solution, and let it stand for 24 hours to form a uniform and stable transparent tin fluoride sol.

[0036] 2) Take 15ml of tetraethyl orthosilicate and slowly drop it into 30ml of absolute ethanol, stir fo...

Embodiment 2

[0048] Example 2 Effect of annealing process on fluorine-doped tin dioxide transparent conductive film

[0049] (1) Preparation method

[0050] Method is with embodiment 1, difference is in 4) step.

[0051] 4) Spin coating with a homogenizer, the speed of the homogenizer is 3000r / min, the time is 30s, first spin coat a layer of SiO 2 Sol, and then spin-coat tin fluorosol, put the coated glass sheet into an oven at 100°C to dry, then transfer to a high-temperature muffle furnace to dry at 500°C for 15 minutes, cool naturally to room temperature, and repeat the above operations to achieve the desired film thickness. Finally, annealing is carried out under nitrogen, vacuum or air respectively to obtain the target product fluorine-doped tin dioxide transparent conductive film respectively.

[0052] (2) Detection

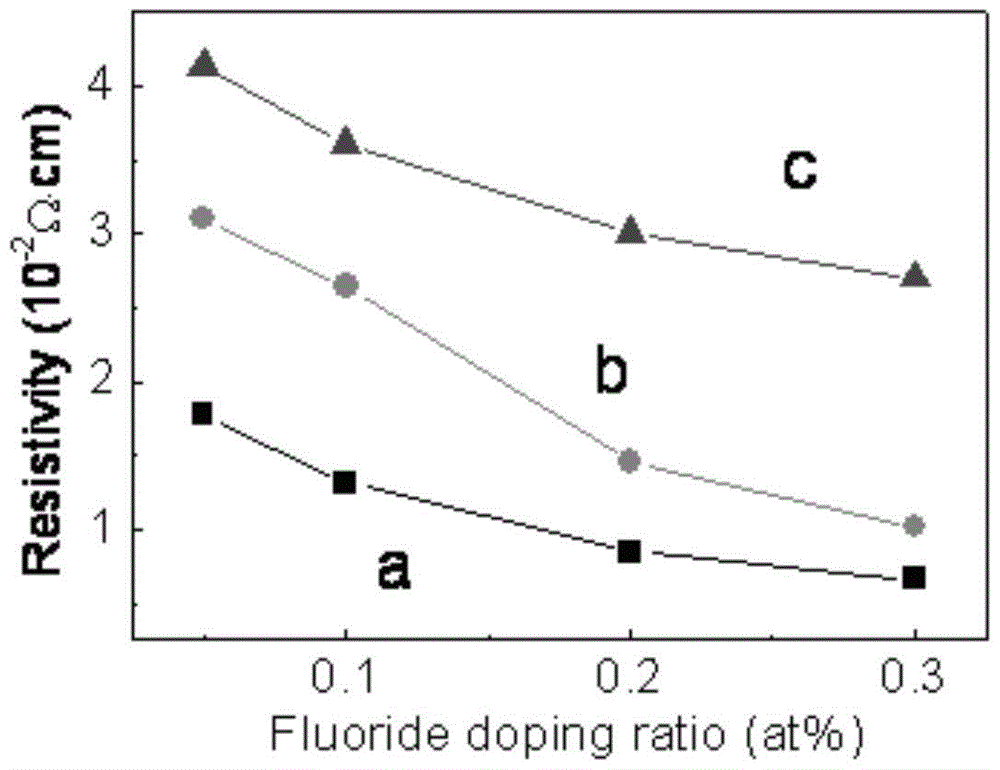

[0053] 1. Conductivity

[0054] The resistivity test was carried out on the films annealed in nitrogen, vacuum and air respectively by Hall effect instrument, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com