A kind of magnesium alloy with high electrical conductivity and high shielding effectiveness and preparation method thereof

A technology with shielding efficiency and high electrical conductivity, applied in the field of shielding materials and metal materials, can solve the problems of electromagnetic shielding performance not as good as metal, low strength, etc., and achieve the effect of excellent plastic processing performance, low cost and high electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

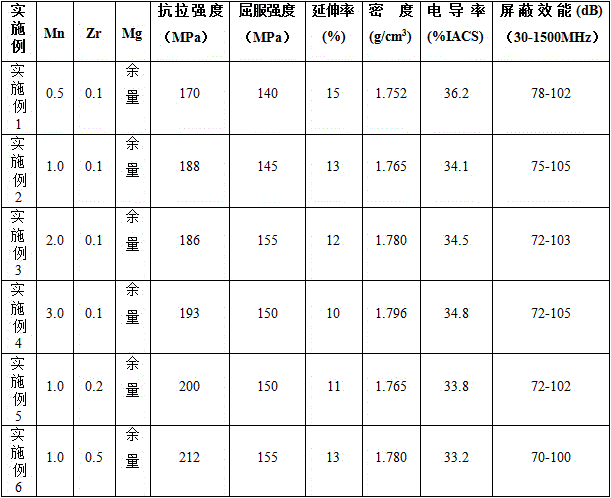

Examples

preparation example Construction

[0025] The method for preparing the above-mentioned magnesium alloy with high electrical conductivity and high shielding effectiveness of the present invention comprises the following steps:

[0026] 1) Melting and casting ingots: Weigh each raw material according to the composition requirements, among which manganese is a magnesium-manganese master alloy, and zirconium is a magnesium-zirconium master alloy. 99% CO by volume 2 and 1% SF 6 Under the protective gas formed, the magnesium is first smelted between 720°C and 740°C. After it is completely melted and the temperature rises to 740°C and stabilizes, then the magnesium-manganese and magnesium-zirconium master alloys preheated to about 200°C are added to make the magnesium-manganese and the magnesium-zirconium master alloy are melted and fully stirred for 3-6 minutes, and the melt is left to stand at 740°C for 10-20 minutes, and the surface scum is removed, and it is poured at 740°C until it is preheated to 250-350°C. In...

Embodiment 1

[0034] A method for preparing a novel magnesium alloy with high electrical conductivity and high shielding performance, comprising the steps of:

[0035] 1. Ingredients: 5wt.% magnesium-manganese, 30wt.% magnesium-zirconium master alloy and pure magnesium 99.98wt.%Mg are used as raw materials. According to the embodiment, the formula is 0.5wt.% Mn, 0.1wt.% Zr, and the balance is industrial For pure magnesium Mg, calculate and weigh three raw materials.

[0036] 2. Smelting: Under the cover of 99%CO2+1%SF6 (volume percentage) gas, first smelt industrial pure magnesium at 720℃~740℃. Heat the magnesium-manganese and magnesium-zirconium master alloys to 200°C, and stir them fully for 3-6 minutes, then let the melt stand at 740°C for 10-20 minutes, and pour it at 740°C until it is preheated to 250-350°C In the iron mold, a magnesium alloy ingot is prepared.

[0037] 3. Homogenization treatment: Cover the prepared magnesium alloy ingot with graphite, homogenize it at 480° C. for 2...

Embodiment 2

[0042] A method for preparing a novel magnesium alloy with high electrical conductivity and high shielding performance, comprising the steps of:

[0043] 1. Ingredients: 5wt.% magnesium-manganese, 30wt.% magnesium-zirconium master alloy and industrial pure magnesium 99.98wt.%Mg are used as raw materials. According to the embodiment, the formula is 1wt.% Mn and 0.1wt.% Zr. Magnesium Mg, calculate and weigh the three raw materials.

[0044] 2. Smelting: Under the cover of 99%CO2+1%SF6 (volume percentage) gas, first smelt industrial pure magnesium at 720℃~740℃. Heat the magnesium-manganese and magnesium-zirconium master alloys to 200°C, and stir them fully for 3-6 minutes, then let the melt stand at 740°C for 10-20 minutes, and pour it at 740°C until it is preheated to 250-350°C In the iron mold, a magnesium alloy ingot is prepared.

[0045] 3. Homogenization treatment: cover the prepared magnesium alloy ingot with graphite, homogenize it at 500° C. for 20 hours, and then water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com