Lubricating grease prepared by using waste gear oil and method for preparing lubricating grease

A gear oil and lubricating grease technology, which is applied in the direction of lubricating compositions and the petroleum industry, can solve the problems of difficult waste water and waste residue treatment, high energy consumption of solvent recovery, and large environmental hazards, so as to improve the resource reuse rate and realize Effects of resource regeneration and harm reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

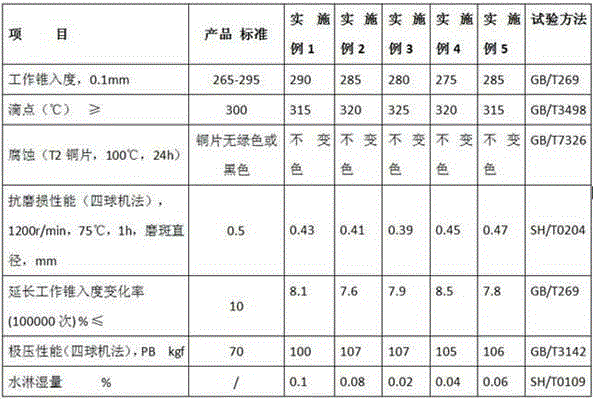

Examples

Embodiment 1

[0021] The method for preparing lubricating grease from waste gear oil in this embodiment is as follows:

[0022] Process (1): Deep purification and transformation of gear oil, the steps are as follows:

[0023] (1) Heat the recovered waste gear oil, control the temperature below 60℃, stir evenly, and use positive electricity to neutralize the negative charge of lubricating oil impurity ions to eliminate electrostatic repulsion and facilitate the sedimentation of impurity particles and the separation of water. Settling time is not less than 4 hours, and the large particles of impurities and moisture are initially removed.

[0024] (2) The gear oil obtained in step (1) is centrifuged for multiple cycles through a high-speed centrifuge to remove medium-sized particles and trace moisture. The number of centrifugal separations depends on the impurities and moisture content of the waste gear oil, at least not less than 4 times;

[0025] (3) The gear oil obtained in step (2) is subjected t...

Embodiment 2

[0040] Process (1): The process steps of deep purification and conversion of gear oil are the same as the process (1) of Example 1;

[0041] Process (2): Preparation of high-performance calcium sulfonate grease from waste gear oil in this example is made of raw materials with the following weight components: 32% of advanced waste gear oil, 44% of calcium sulfonate with high alkali value, Dodecylhydroxystearic acid 5%, transforming agent 7.5%, water 6%, boric acid 2.0%, sulfide isobutylene 0.6%, calcium hydroxide 0.7%, N-phenyl-a naphthylamine 1.3%, random polypropylene 0.9% .

[0042] The preparation process is as follows:

[0043] (1) Add 320Kg of gear oil and 440Kg of calcium sulfonate after deep purification and conversion into the reactor, heat to 80℃, and stir for 30min at constant temperature;

[0044] (2) Add 50Kg of dodecylhydroxystearic acid to the material obtained in step (1), stir at 80°C, wait for it to completely melt, add 75Kg of transforming agent and 60Kg of water, a...

Embodiment 3

[0051] The method for preparing lubricating grease from waste gear oil in this embodiment is as follows:

[0052] Process (1): The process steps of deep purification and conversion of gear oil are the same as the process (1) of Example 1;

[0053] Process (2): Preparation of high-performance calcium sulfonate grease from waste gear oil of this embodiment is made of raw materials with the following weight components: 34.1% of advanced waste gear oil, 40% of calcium sulfonate with high alkali value, Alkylbenzene sulfonic acid 6%, transforming agent 8%, water 6.5%, boric acid 1.0%, triphenyl phosphate and isobutylene sulfide 1.1%, calcium hydroxide 0.6%, diphenylamine and N-phenyl-a naphthylamine 1.6% , Ethylene-propylene copolymer and random polypropylene 1.1%.

[0054] The preparation process is as follows:

[0055] (1) Add 341Kg of converted gear oil and 400Kg of calcium sulfonate to the reaction kettle in process (1) deep purification, heat to 70℃, and stir for 30min at constant tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com